Self-flushing submersible electric pump and method for flushing sediments at its bottom

A submersible electric pump and self-flushing technology, which is applied to components, pumps, pump devices, etc. of pumping devices for elastic fluids, can solve the problems of reduced reliability, uneconomical, and increased energy consumption of water pumps, and achieve prevention Or prevent sedimentation, prevent or prevent sedimentation, and spray far away

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

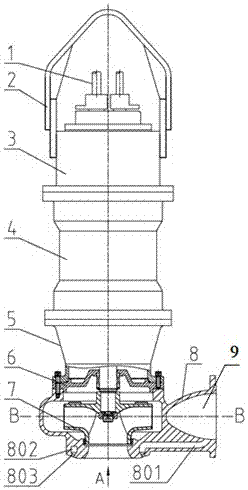

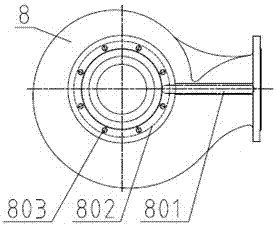

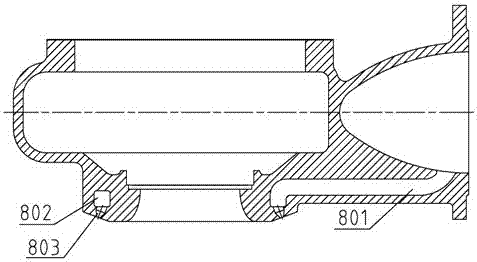

[0025] A self-flushing submersible electric pump, comprising a motor 4, a cable 1, a junction box 3, a pump cover 6, an impeller 7 and a volute 8, the motor 4 and the cable 1 are connected in the junction box 3, and the pump cover 6 is connected to the volute 8 communication constitutes an impeller chamber, the impeller 7 is located in the impeller chamber, the rotating shaft of the motor 4 passes through the pump cover 6, and is connected with the impeller 7, and the volute 8 is provided with a water inlet and a water outlet 9, and in the volute 8 A nozzle 803 and a water inlet channel 801 for scouring the lower part of the submersible electric pump are provided on the upper part. In this embodiment,

[0026] An annular channel 802 is provided on the volute 8, and the other end of the water inlet channel 801 is connected to the nozzle 803 through the annular channel 802; the water inlet channel 801 is located at the water outlet of the volute 8, and the annular channel 802 L...

Embodiment 2

[0028] A method for scouring the sediment at the bottom of a submersible electric pump, a nozzle 803 with a downward spraying direction is installed on the volute 8 of the submersible electric pump, and an inlet for communicating the water inlet and the nozzle 803 is opened on the volute 8 of the submersible electric pump. Water channel 801; install the submersible electric pump to a predetermined underwater area, start the submersible electric pump, the high-pressure water flow generated by the impeller 7 of the submersible electric pump doing work flows into the volute 8, and the maximum pressure is formed near the water outlet of the volute 8 , the water inlet channel 801 leads part of the high-pressure water flow to the nozzle 803, and sprays high-pressure water to the lower part of the submersible electric pump through the nozzle 803, and uses the high-pressure water to wash or clean the lower part of the submersible electric pump to prevent the sedimentation or washing awa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com