A moving electrode non-destructive testing device for pipelines applied to electric field fingerprinting

A technology of moving electrodes and electric field fingerprints, which is applied in the field of pipeline non-destructive testing technology equipment, can solve problems such as inability to weld, difficult welding operations, and easy corrosion of welded joints, to achieve convenient positioning and collection, convenient and reasonable settings, and reduce construction costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

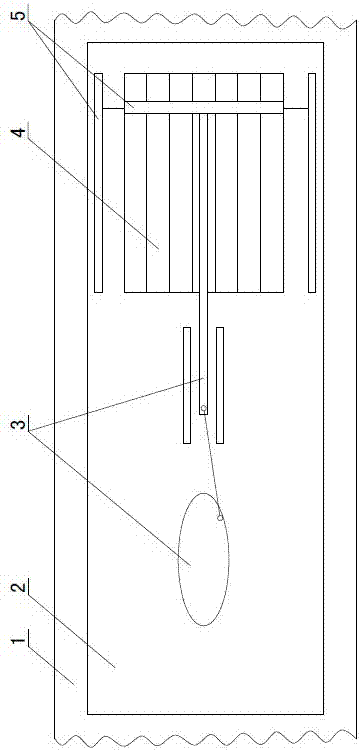

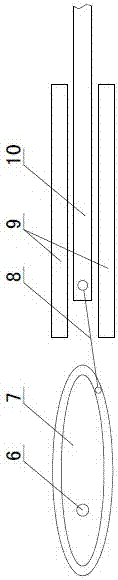

Examples

Embodiment 2

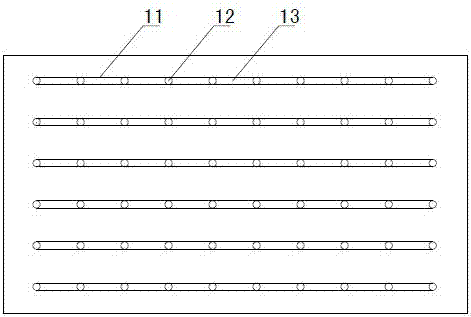

[0062]The difference between this embodiment and Embodiment 1 lies in that the structures of the collection tank unit 4 and the corresponding reciprocating collection unit 5 are different.

[0063] Such as Figure 8 As shown, in the collection tank unit 4 , the collection tank 11 is replaced by a return type collection tank 27 . The return collection tank 27 is also opened on the base plate 2 . The quantity of return type collection groove 27 and the spacing of adjacent two return type collection grooves 27 are determined by detection scheme; In each return type collection groove 27, a plurality of data collection holes 13 are arranged, the quantity of data collection holes 13 and relative The distance between two adjacent data collection holes 13 is also determined by the detection scheme.

[0064] Return rings 26 are provided at both ends of each return collection tank 27 . The return collection tank 27 extends horizontally to form a horizontal section of the return ring ...

Embodiment 3

[0069] The difference between Embodiment 3 and Embodiment 1 is that in this embodiment, both the reciprocating driving unit 3 and the reciprocating collecting unit 5 are directly fixed on the pipeline 1 to be tested, and the bottom plate 2 is only used for setting the collecting tank unit 4 .

Embodiment 4

[0071] The difference between Embodiment 4 and Embodiment 1 is that in this embodiment, travel switches are arranged at both ends of the collection tank 11, the contacts of the travel switch are connected to the controller, and the controller is connected to the motor for controlling the motor. positive and negative. When the probe bracket 15 moves to a certain end of the collection tank 11, the corresponding travel switch is triggered, and at this time the travel switch outputs a control signal to the controller, and the controller controls the motor to rotate in the opposite direction to push the probe bracket 15 in the opposite direction. movement to realize the reciprocating movement of the probe holder 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com