Pipeline defect type distinguishing method based on ultrasonic guided waves

A defect type, ultrasonic guided wave technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, and processing the response signals of detection. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0033] A method for discriminating pipeline defect types based on ultrasonic guided waves, comprising the following steps:

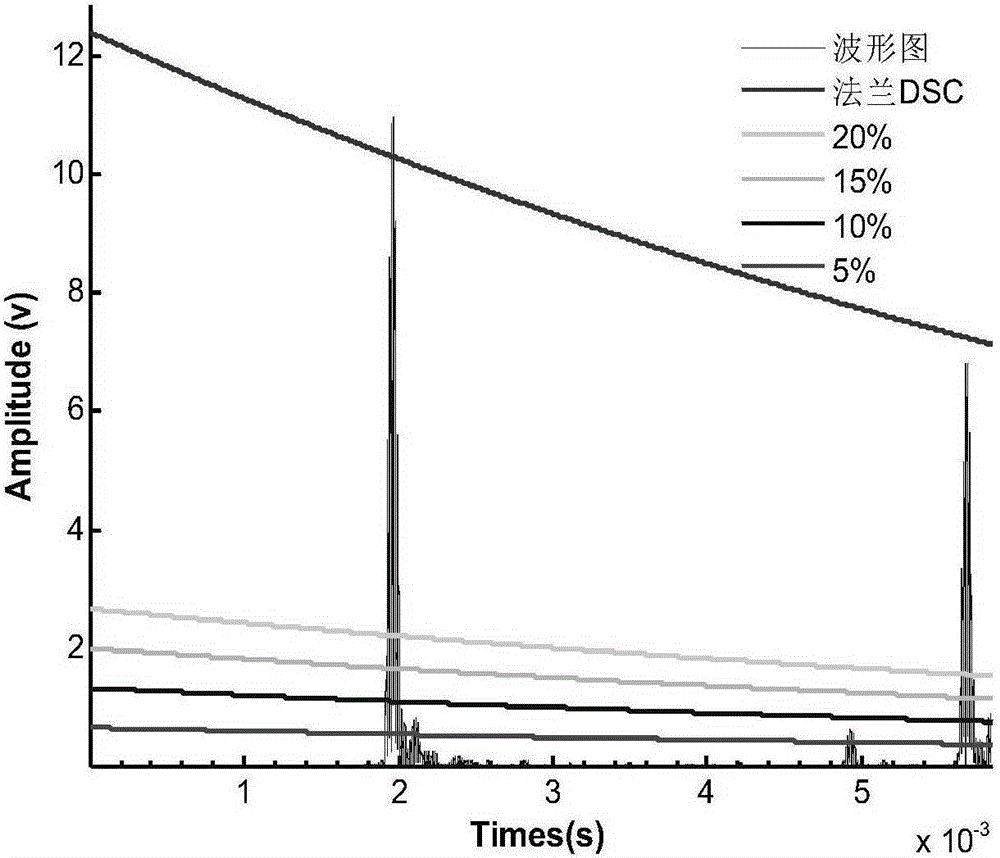

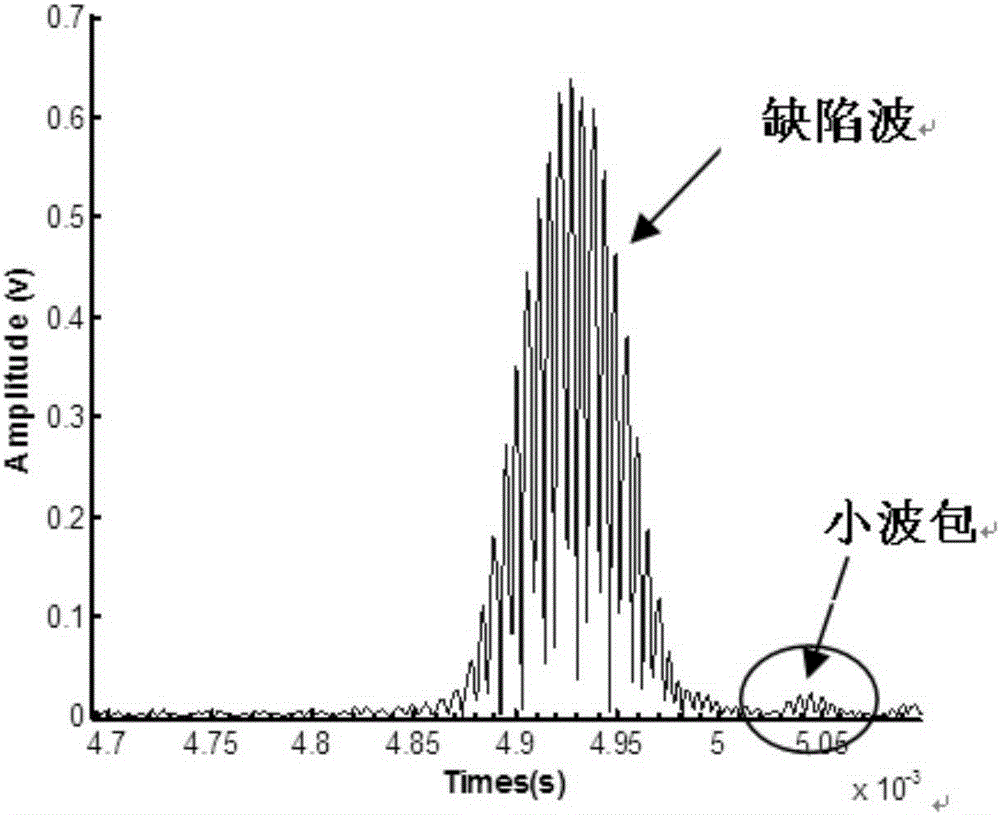

[0034] S1: Take a standard pipeline with a length of 9m, an outer diameter of 108mm, and a wall thickness of 5mm with uniform medium and no defects. The material of the pipeline is 45# steel; make a circumferential crack with a section defect rate of 8.5% and a width of less than 2mm in one place of the pipeline For defects, the guided wave sensors are evenly distributed on the pipeline in the circumferential direction, and the guided wave sensors excite ultrasonic guided waves to detect the pipeline. The distance between the defect and the detection position is 7.5m; without changing the cross-sectional defect rate of 8.5%, the width of the crack de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com