Exhaust silencer achieving air inflow adjustment

An exhaust muffler and adjustable technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of difficult to control the intake air volume, incomplete function of the muffler, high cost, etc., and achieve the effect of preventing dust, simple structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

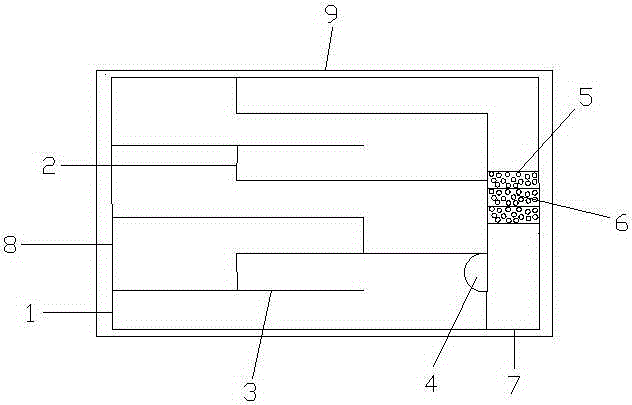

[0020] Example: such as figure 1 As shown, an exhaust muffler with adjustable air intake in the present invention comprises an air inlet 1, a first muffler net 2, a sound insulation board 3, a small fan 4, a second muffler net 5, activated carbon 6, and an air outlet 7. Housing 8 and dustproof cover 9; it is characterized in that, the housing 8 is provided with a plurality of the sound insulation boards 3, the first noise elimination net 2 is arranged between the sound insulation boards 3, and the The upper right side of the air inlet 1 is provided with a small fan 4, the air inlet 1 and the air outlet 7 are respectively connected to the housing 8, and the upper part of the air outlet 7 is provided with a plurality of second Muffling net 5.

[0021] Further, in order to make the air flow smoothly and increase the noise reduction effect, the sound insulation board 3 forms a plurality of internal passages.

[0022] Further, in order to purify the air and prevent pollution, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com