Flexible light wide-temperature leaky coaxial cable

A leaky coaxial cable, lightweight technology, used in circuits, leaky waveguide antennas, etc., can solve problems such as affecting performance, coaxial cable opening deformation, penetration, etc., to achieve good high and low temperature resistance and mechanical properties, good flexibility and environmental protection The effect of weather resistance, good high temperature resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

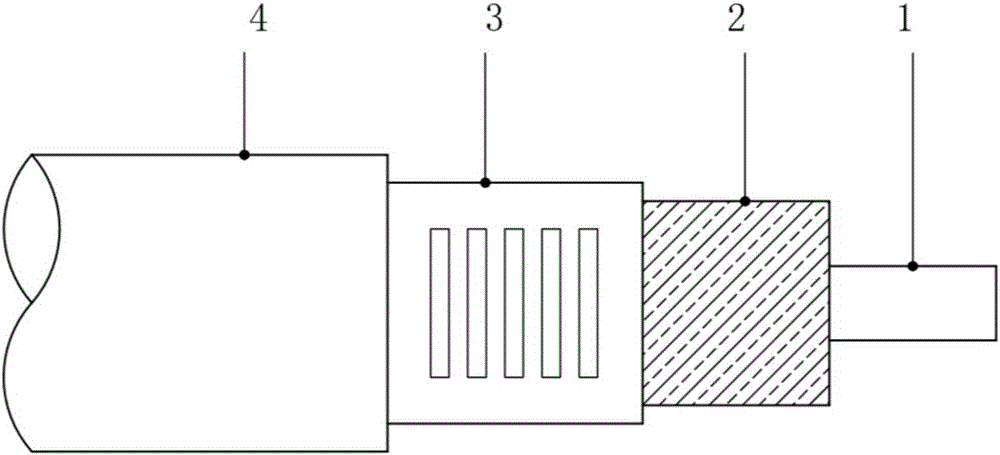

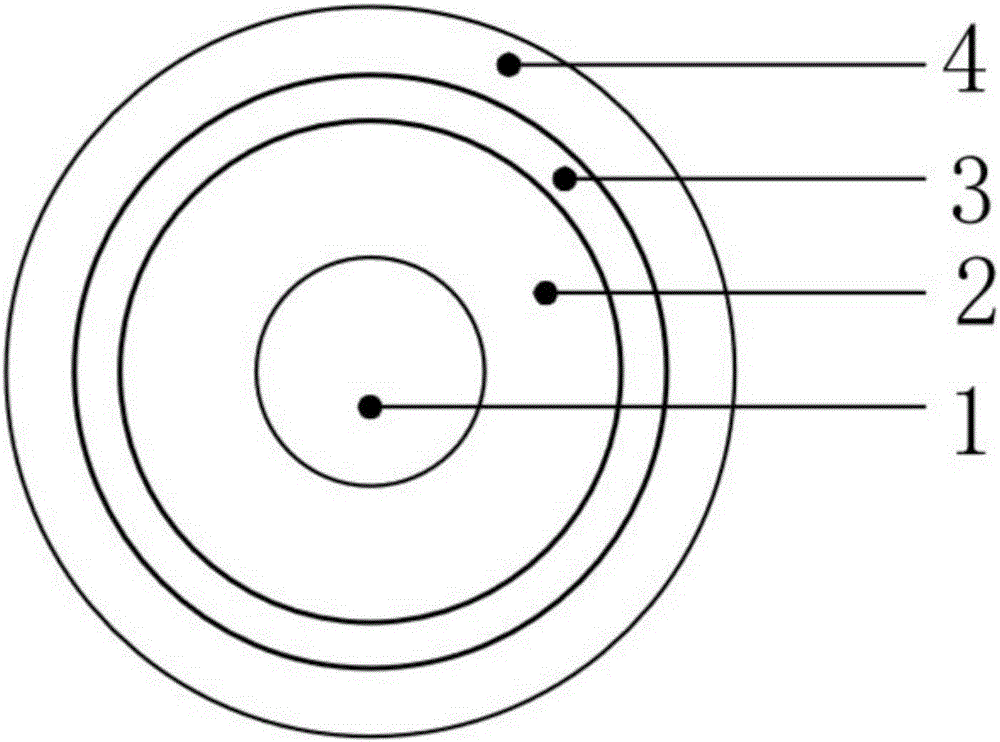

[0027] Attached below figure 1 , attached figure 2 The present invention is further implemented and described:

[0028] A flexible light-duty wide-temperature leaky coaxial cable, which is arranged sequentially from the inside to the outside: a cable inner conductor 1, an insulating layer 2, an outer conductor 3 and a sheath layer 4, and the inner conductor 1 and the outer conductor 3 of the cable are made of carbon It is composed of nanotube fiber material; the outer conductor 3 is provided with slots, and the slots are uniform in size. In the embodiment, the slots are vertical holes arranged uniformly.

[0029] Specific as attached figure 1 A flexible lightweight wide temperature leakage coaxial cable is shown, with figure 1 Shown is a schematic diagram of the cross-sectional structure of the leaky coaxial cable proposed by the present invention. as attached figure 1 As shown, the leaky coaxial cable includes an inner conductor, an insulating layer, an outer conductor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com