Resin composition and prepreg and laminated board fabricated by using same

A technology of resin composition and prepreg, which is applied in the field of resin composition, prepreg and laminate, can solve the problems of no halogen-free flame retardant, toxic hydrogen halide gas, harm to human health, etc., and achieve excellent dielectric properties, low Effects of dielectric constant and excellent heat and humidity resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

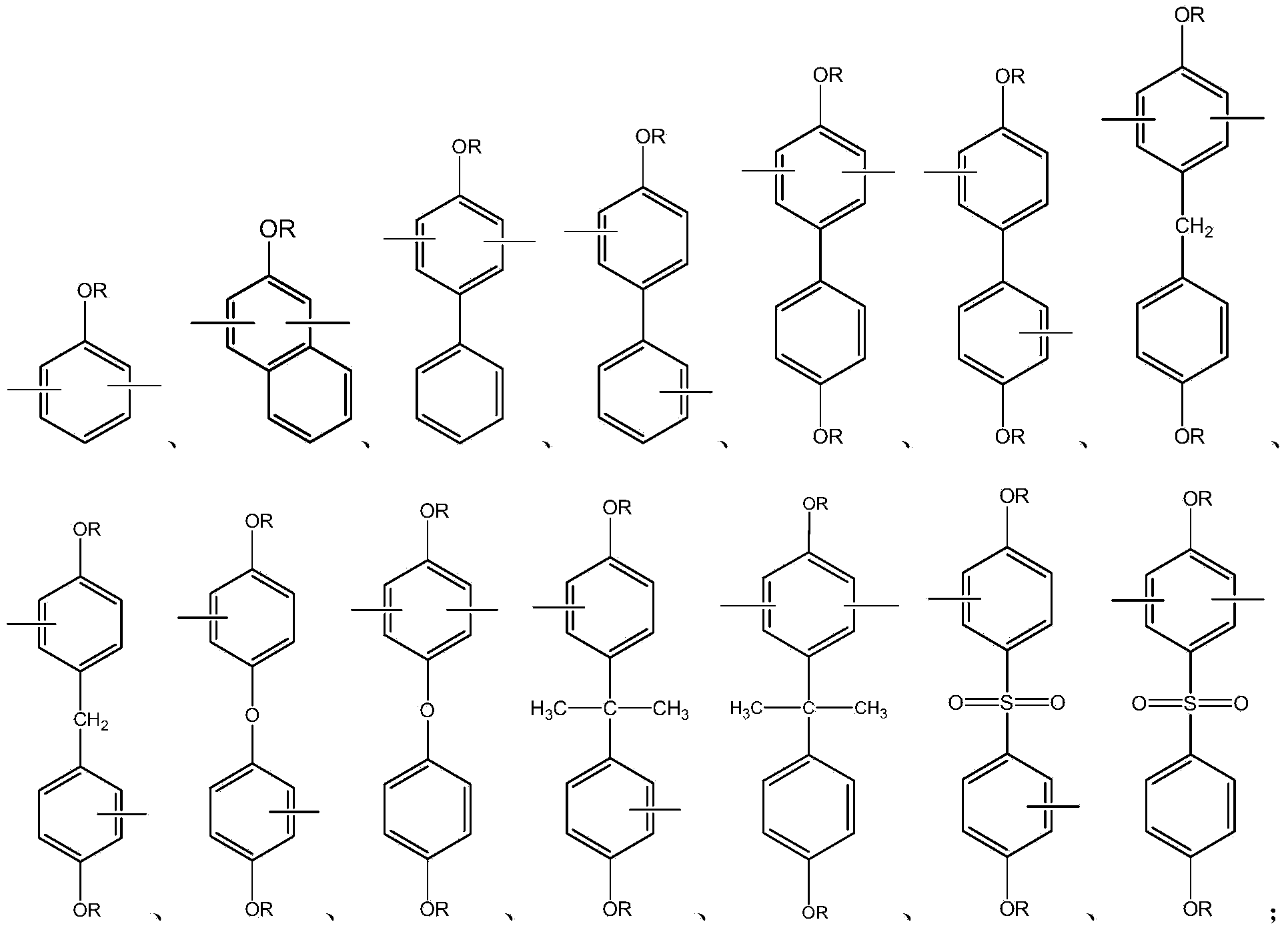

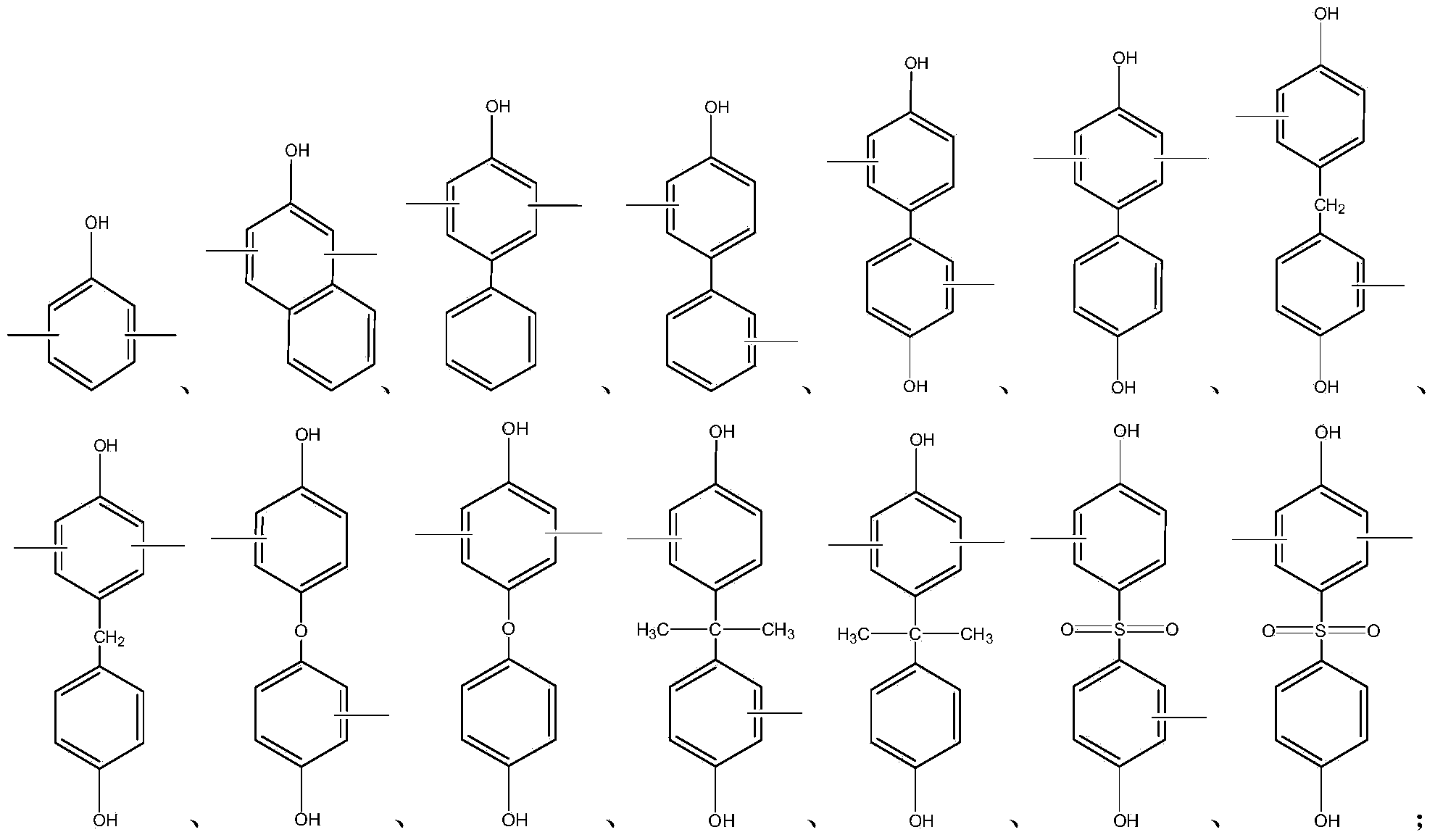

Method used

Image

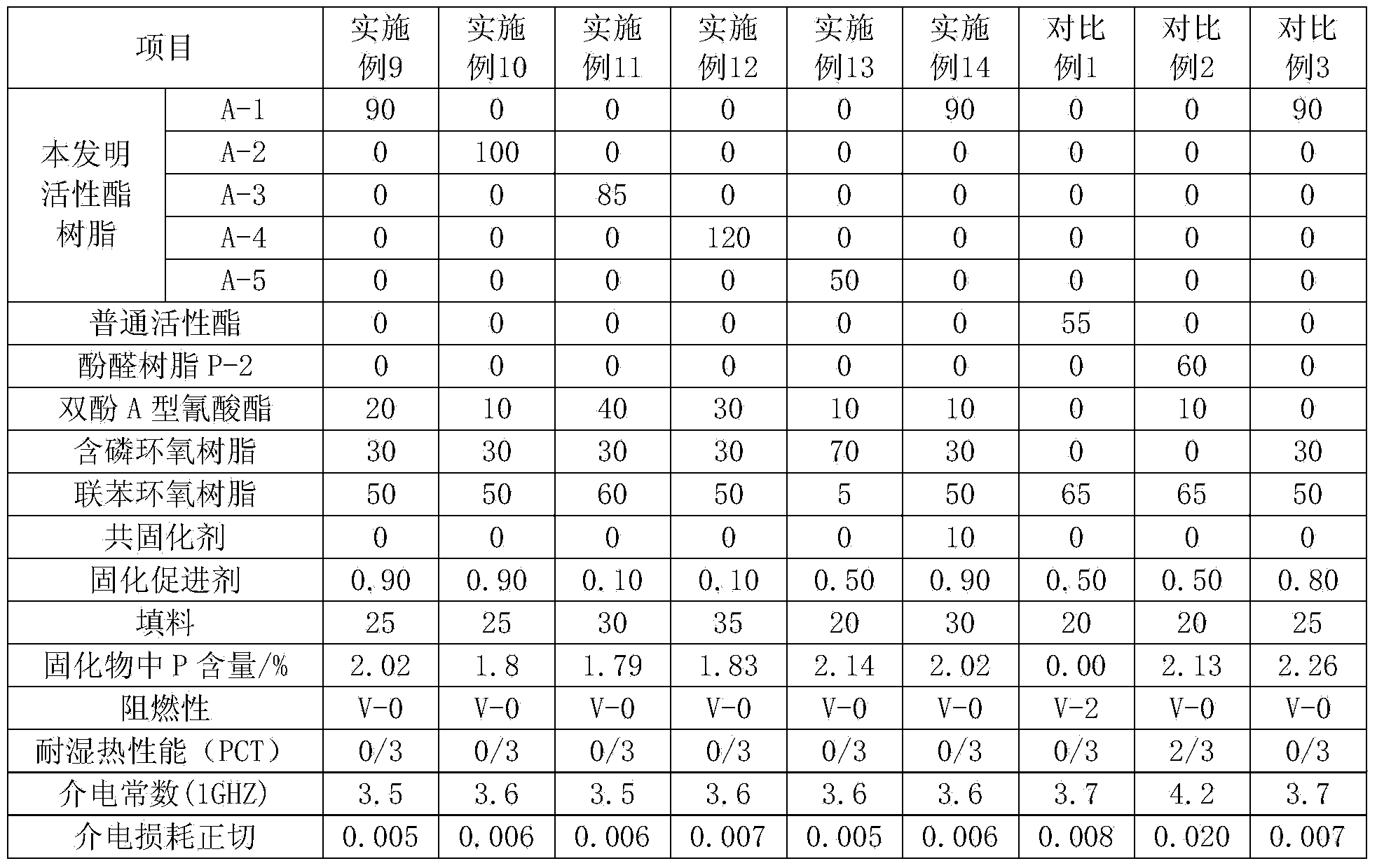

Examples

Embodiment and

[0052] Embodiment and comparative example:

[0053] Examples 1-3 are the synthesis of nitrogen-containing and phosphorus-containing multifunctional phenolic compounds of the present invention, Examples 4-8 are the synthesis of active ester resins, and Examples 9-14 and Comparative Examples 1-3 are the preparation and physical properties of the resin composition evaluate. Unless otherwise specified below, "parts" represent "parts by weight", and "%" represent "% by weight".

Embodiment 1

[0055] Drop into N-(4-hydroxyphenyl)maleimide (50g, 0.265mol), phenol (50g, 0.532mol) and oxalic acid (5g) in the there-necked flask that thermometer, condensing tube, stirrer are installed, mix After stirring evenly, place it in a constant temperature water bath at 70°C; then, under stirring, add formaldehyde solution (55mL, 37% formaldehyde aqueous solution, the ratio of phenol / aldehyde is 1 / 0.8) dropwise to the flask for 0.5 hours; After formaldehyde, maintain the temperature of 70°C and stir for 15 hours; then, dissolve and dilute the reaction product with 200mL acetone, and then precipitate the reaction product with 40% methanol aqueous solution; repeat the above dissolution-precipitation operation 3 to 5 times, It is filtered, separated, and dried to obtain pure nitrogen-containing polyfunctional phenolic compound; then, take the above-mentioned synthetic nitrogen-containing polyfunctional phenolic compound (50 g), and -10-Oxa (24g, 0.116mol) was added to a three-necked ...

Embodiment 2

[0057] Drop into N-(4-hydroxyphenyl)maleimide (50g, 0.265mol), bisphenol A (50g, 0.201mol) and oxalic acid (5g) in the there-necked flask that thermometer, condensing tube, stirrer are installed After mixing and stirring evenly, place it in a constant temperature water bath at 70°C; then, under stirring, add formaldehyde solution (35mL, 37% formaldehyde aqueous solution, the ratio of phenol / aldehyde is 1 / 0.8) to the flask dropwise for 0.5 hours; After adding formaldehyde, maintain the temperature of 70°C and stir for 15 hours; then, dissolve and dilute the reaction product with 200mL acetone, and then precipitate the reaction product with 40% methanol aqueous solution; repeat the above dissolution-precipitation operation for 3-5 Once, it was filtered, separated, and dried to obtain a pure nitrogen-containing polyfunctional phenolic compound; Phosphenanthrene-10-oxa (26g, 0.116mol) was added to a three-necked flask equipped with a thermometer, condenser, and stirrer, and 200mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com