Composite anticaking agent used for food-grade potassium chloride

An anti-caking agent, potassium chloride technology, applied in the field of composite anti-caking agent, can solve problems such as affecting the whiteness of salt products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

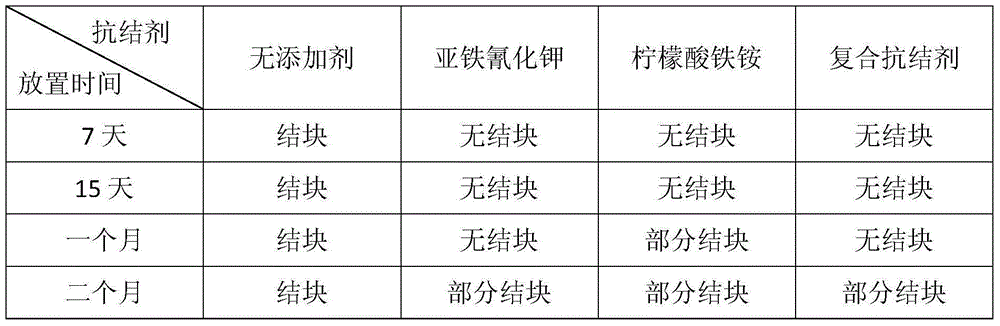

Embodiment 1

[0021] Weigh 53g of D-mannitol, 4.5g of potassium stearate and 42.5g of calcium dihydrogen phosphate, pulverize into powder and mix with 10L of water and stir evenly. It is added to the recrystallization mother liquor which can precipitate 1000KgKCl finished product. After being dried and dried, the mother liquor is put into a ventilated woven bag and placed in an environment at 25°C and a humidity of 50%. The agglomeration status is detected after 7, 15, 30 and 60 days respectively. After testing, the finished product has no agglomeration within one month, and a small amount of agglomeration occurs after 60 days, which has reached the anti-caking effect of industrial food-grade KCl.

Embodiment 2

[0023] Weigh 79g of D-mannitol, 6g of potassium stearate and 15g of calcium dihydrogen phosphate, pulverize into powder and mix with 20L of water and stir evenly. Add it to the recrystallization mother liquor that can precipitate 500KgKCl finished product. After being dried and dried, the mother liquor is put into a ventilated woven bag and placed in an environment at 25°C and a humidity of 50%. The agglomeration status is detected after 7, 15, 30 and 60 days respectively. After testing, the finished product has no agglomeration within two months, and it has reached the anti-caking effect of industrially produced food-grade KCl.

Embodiment 3

[0025] Weigh 53g of D-mannitol, 4.5g of potassium stearate and 42.5g of calcium dihydrogen phosphate, pulverize the ingredients and mix them with 10kg of KCl finished product to form a semi-finished product. Put the above-mentioned semi-finished product and the sample just after drying into the air-permeable woven at the same time In the bag, the mixing mass ratio of the two is 1:200. The bagged samples were placed in an environment at 25° C. and a humidity of 50%, and the agglomeration was detected after 7, 15, 30, and 60 days. After testing, the finished product has no agglomeration within one month, and a small amount of agglomeration occurs after 60 days, which has reached the anti-caking effect of industrial food-grade KCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com