Water-based ceramic material for 3D printing and preparation method thereof

A technology of 3D printing and ceramic materials, applied in the field of composite materials, can solve the problems of reducing ceramic products, high cost of additives, non-environmental protection, etc., and achieve the effect of ensuring environmental protection and good physical and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for preparing a water-based ceramic material for 3D printing, comprising the following steps:

[0028] S1, the ceramic base material is successively subjected to coarse crushing, medium crushing, fine crushing, screening, pressure filtration, and mud refining to obtain raw mud;

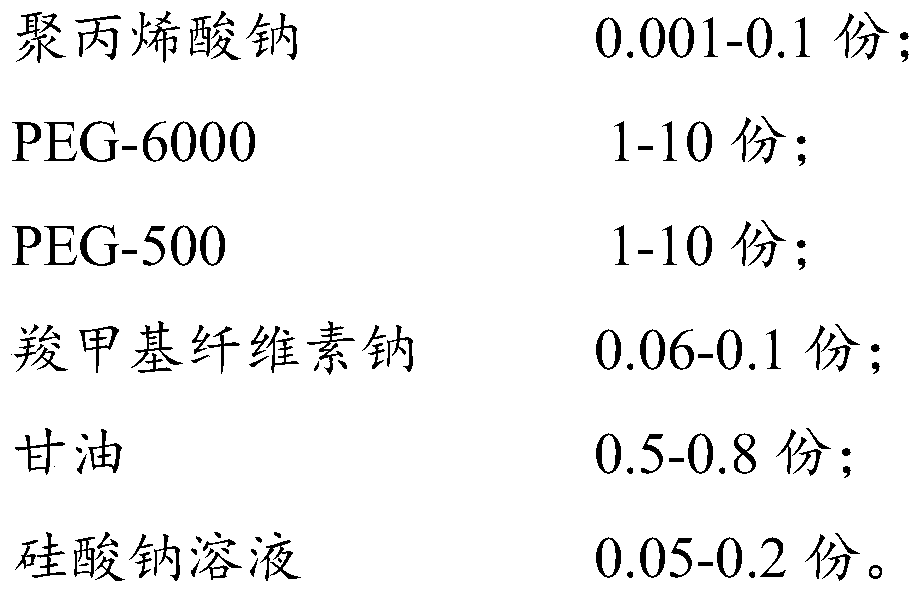

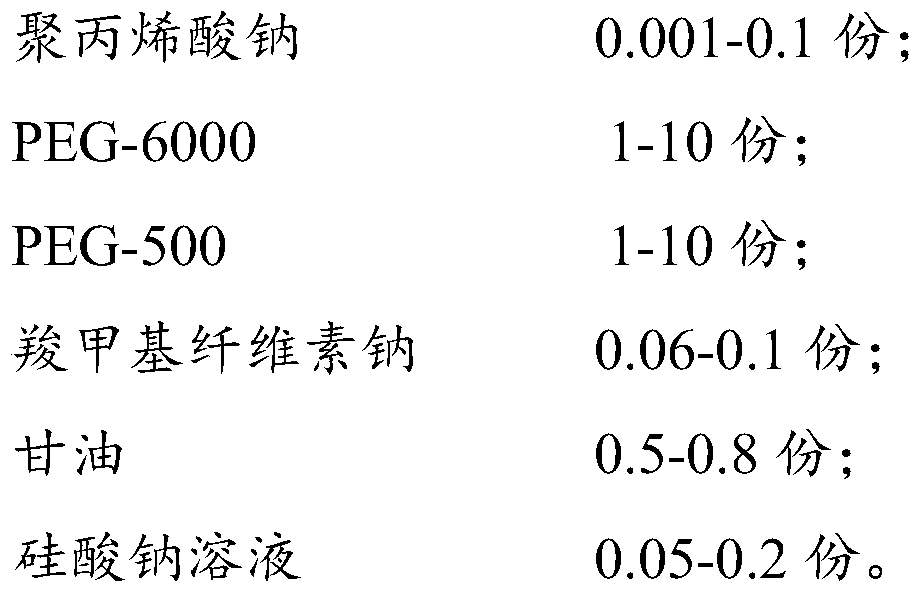

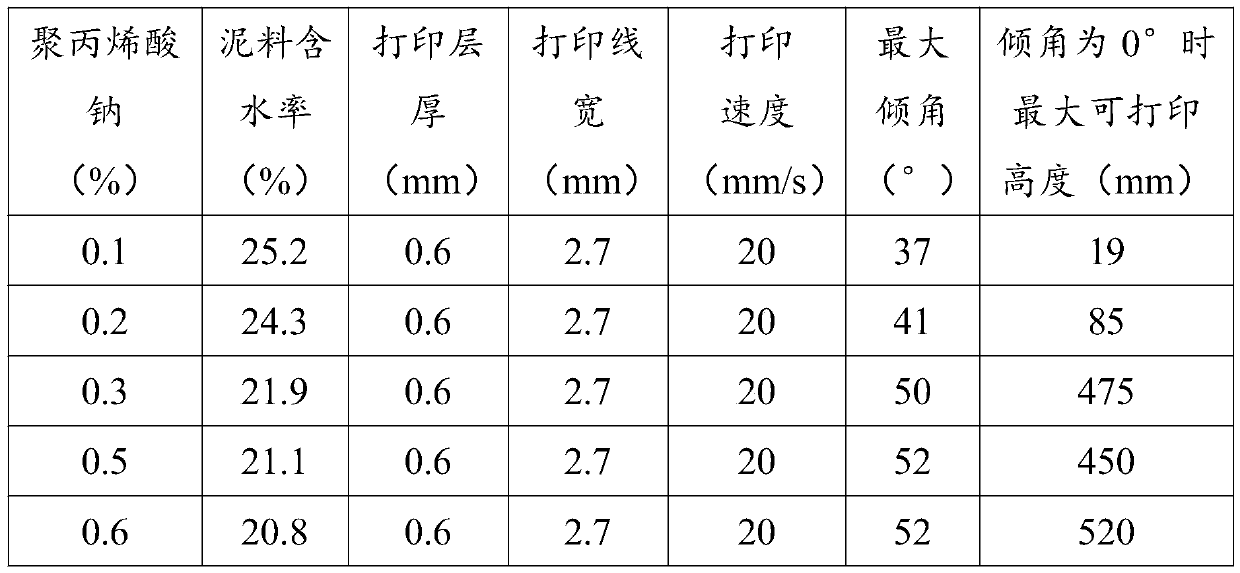

[0029] S2. Add sodium polyacrylate, 9 parts of PEG-6000, 7 parts of PEG-500, 0.08 parts of sodium carboxymethylcellulose and 0.7 parts of glycerin in the modifier to industrial water, and stir at a medium speed for 20 minutes until Dissolve completely, make modification solution; The ratio of the addition amount of described modification agent and industrial water is 0.002:26;

[0030] S3, adding the raw mud to the modified solution prepared in step S2, and stirring in stages under vacuum conditions to obtain the mud; the ratio of the added amount of the raw mud, modifier and industrial water is 100: 0.002:26; described modifying agent is also added with Kathon; the addition of descri...

Embodiment 2

[0038] A method for preparing a water-based ceramic material for 3D printing, comprising the following steps:

[0039] S1, the ceramic base material is successively subjected to coarse crushing, medium crushing, fine crushing, screening, pressure filtration, and mud refining to obtain raw mud;

[0040]S2. Add sodium polyacrylate, PEG-6000, 7 parts of PEG-500, 0.08 parts of carboxymethylcellulose sodium and 0.7 parts of glycerin in the modifier to industrial water, stir at a medium speed for 20 minutes until completely dissolved, A modified solution is obtained; the ratio of the added amount of the modifier and industrial water is 0.002:26;

[0041] S3, adding the raw mud to the modified solution prepared in step S2, and stirring in stages under vacuum conditions to obtain the mud; the ratio of the added amount of the raw mud, modifier and industrial water is 100: 0.002:26; described modifying agent is also added with Kathon; the addition of described Kathon accounts for 0.08%...

Embodiment 3

[0049] A method for preparing a water-based ceramic material for 3D printing, comprising the following steps:

[0050] S1, the ceramic base material is successively subjected to coarse crushing, medium crushing, fine crushing, screening, pressure filtration, and mud refining to obtain raw mud;

[0051] S2. Add 0.008 parts of sodium polyacrylate, PEG-6000, 7 parts of PEG-500, sodium carboxymethylcellulose and 0.7 parts of glycerin in the modifier to industrial water, stir at a medium speed for 20 minutes until completely dissolved, A modified solution is obtained; the ratio of the added amount of the modifier and industrial water is 0.002:26;

[0052] S3, adding the raw mud to the modified solution prepared in step S2, and stirring in stages under vacuum conditions to obtain the mud; the ratio of the added amount of the raw mud, modifier and industrial water is 100: 0.002:26; described modifying agent is also added with Kathon; the addition of described Kathon accounts for 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com