Imidazolyl group modified silicone oil, and preparation method and application thereof

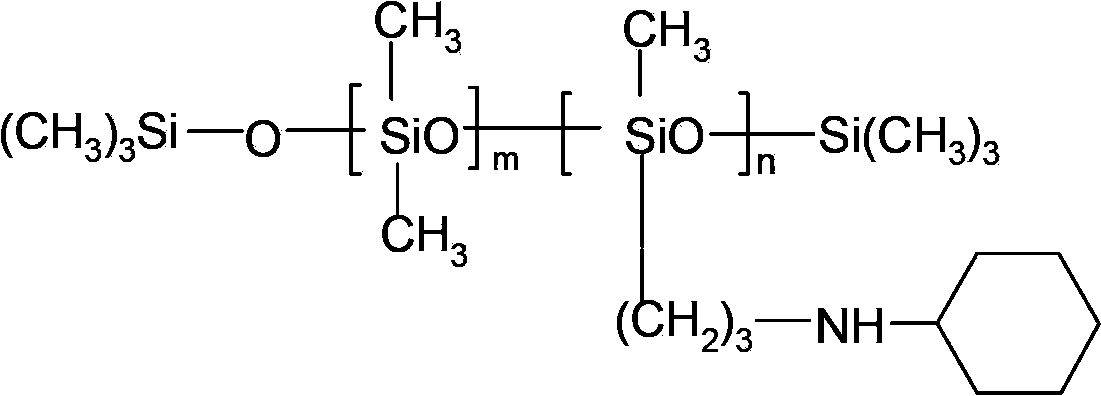

A technology for modifying silicon and imidazole groups, which is applied in the fields of organosilicon material synthesis and fabric finishing. It can solve the problems of complex process, difficult and cumbersome raw materials, etc., and achieve the effect of wide source, simple preparation process and full hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

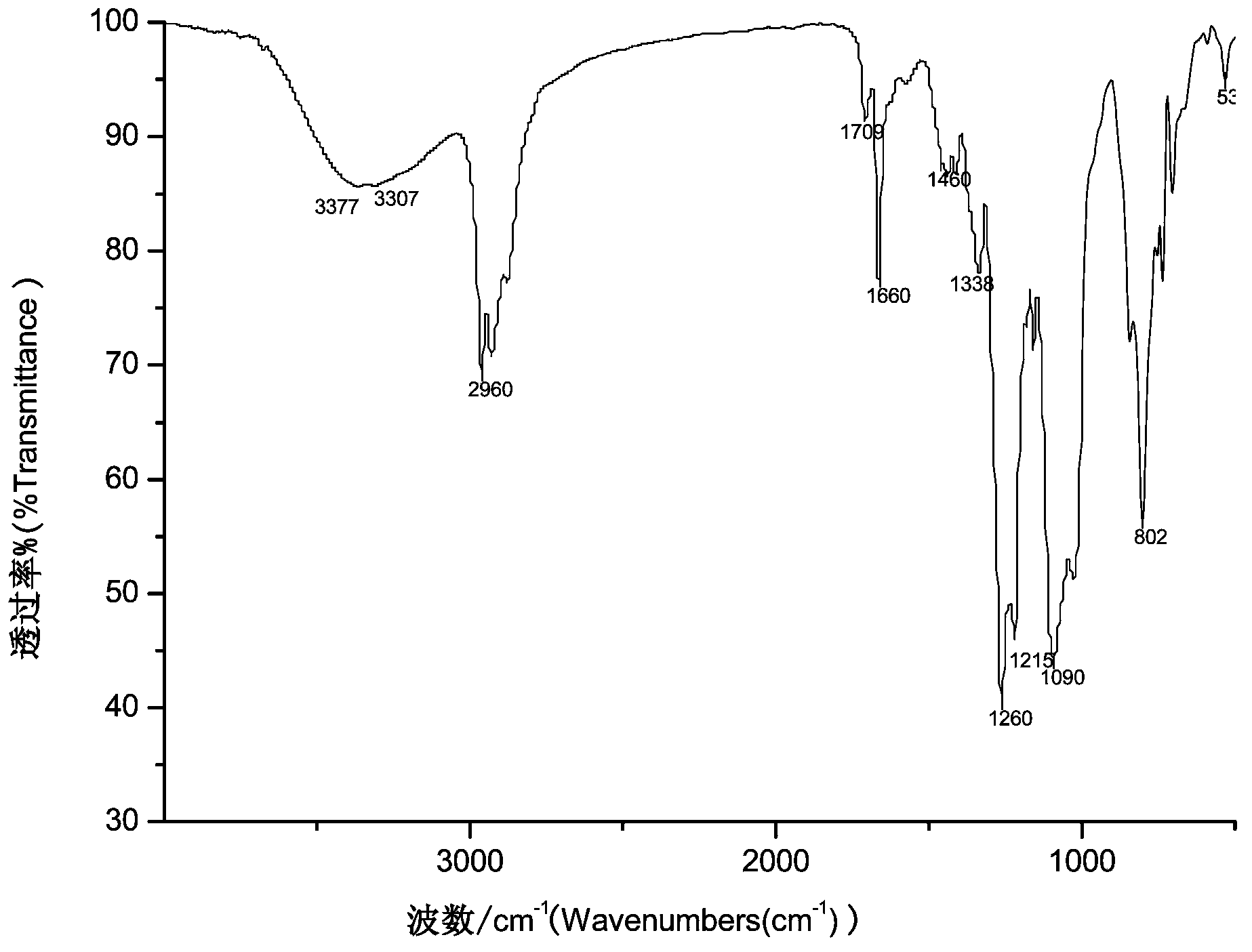

[0034] 1. Preparation of imidazole-β-ethyl methyl silicone oil

[0035] 1000ml four-neck flask, equipped with mechanical stirring, thermometer, constant pressure addition funnel, water separator and reflux condenser.

[0036] Dissolve 125 grams of carboxypropyl silicone oil in 250 grams of toluene to prepare a carboxypropyl silicone oil solution, and add it to a constant-pressure addition funnel. Then, 51.5 grams of ethylenediamine and 100 grams of toluene were added to the reactor in sequence. After the reaction mixture was heated to 110°C, the carboxypropyl silicone oil solution was slowly added dropwise, and the addition was completed in 4 hours. Water reacted for 10 hours.

[0037] 6.5 grams of zinc chloride was added to the above reaction solution, and the temperature was continued at 112° C. for reflux and water separation for 16 hours. After the reaction ended, the reaction was stopped, and 25 grams of water were separated out. Cool the reaction solution, transfer it...

Embodiment 2

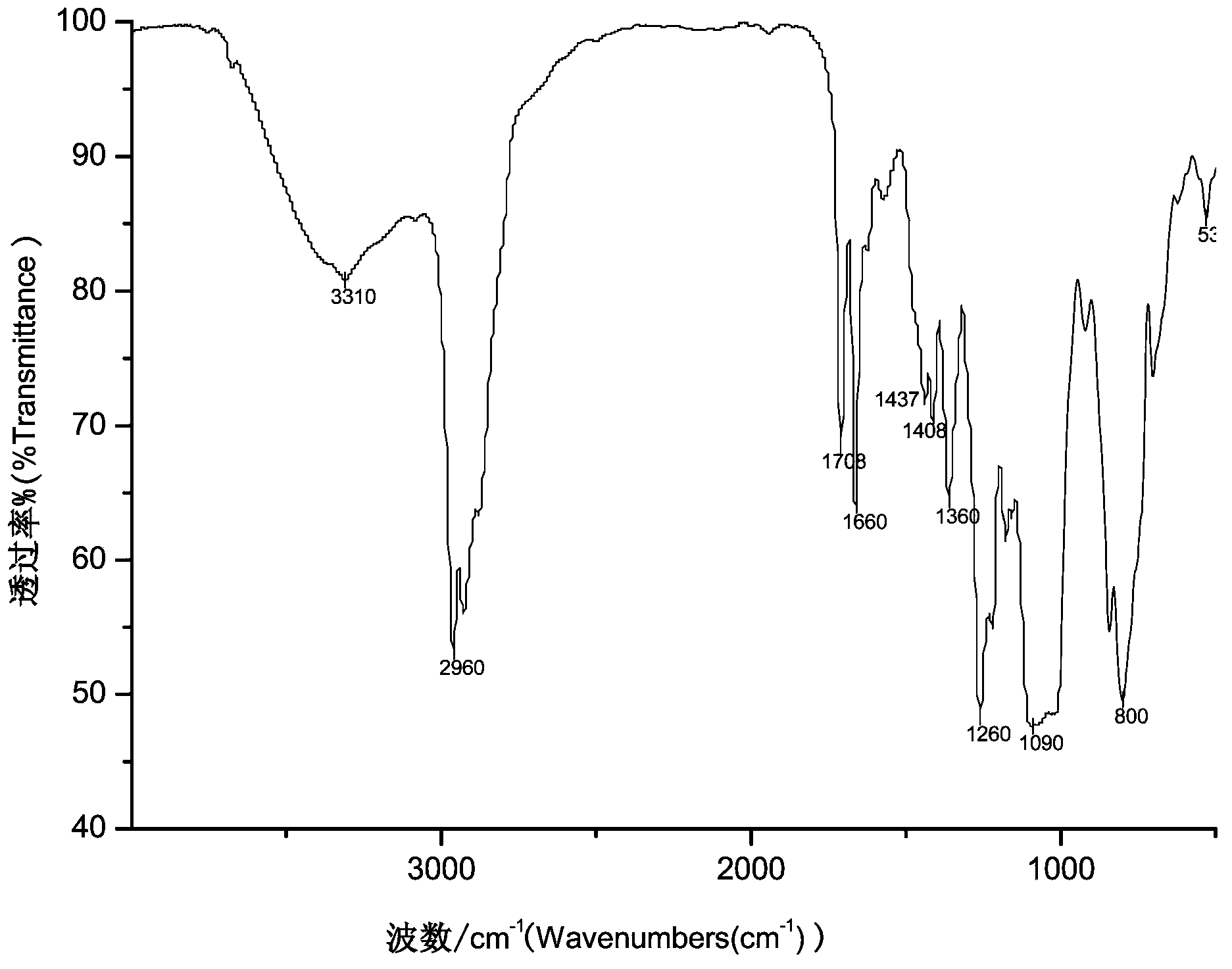

[0047] 1 Preparation of imidazolium decyl methyl silicone oil

[0048] 1000ml four-neck flask, equipped with mechanical stirring, thermometer, constant pressure addition funnel, water separator and reflux condenser.

[0049] Dissolve 180 grams of carboxyundecyl silicone oil in 360 grams of toluene to prepare a carboxyl silicone oil solution, and add it to a constant pressure addition funnel. Then add 55.6 grams of ethylenediamine and 110 grams of toluene to the reactor in sequence. After raising the temperature of the reaction mixture to 110°C, slowly add the carboxyl silicone oil solution dropwise, and finish the dropwise addition in 3 hours. 12 hours.

[0050] 5.4 grams of zinc chloride was added to the above reaction solution, and the temperature was continued at 110° C. for reflux and water separation for 16 hours. After the reaction ended, the reaction was stopped, and 27 grams of water were separated out. Cool the reaction solution, transfer it to a 1000ml separatory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com