Fluorosilicone resin, preparation method and application thereof

A technology of fluorosilicone resin and reaction solution, which is applied in textiles, papermaking, fiber treatment, etc. It can solve the problems of poor moisture permeability and achieve the effects of no change in whiteness, excellent moisture permeability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

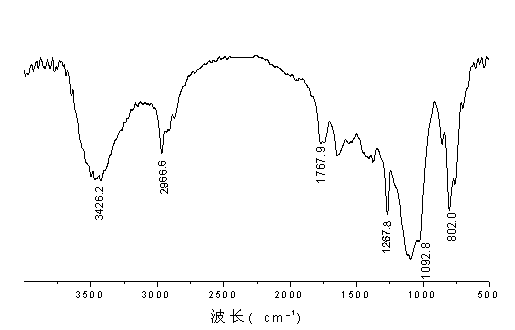

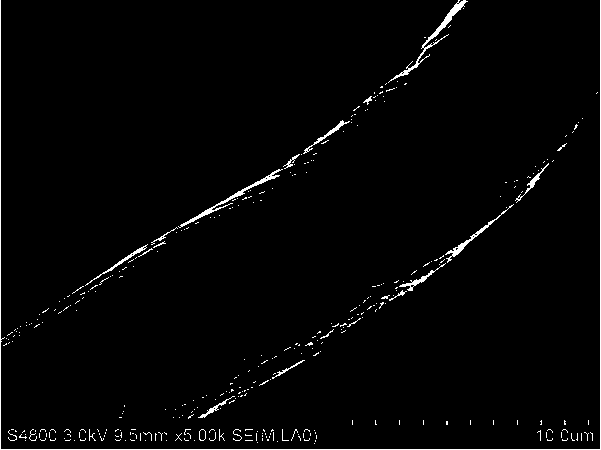

Image

Examples

Embodiment 1

[0028] 1. Synthesis of silicone resin

[0029] The reactor is equipped with mechanical stirring, thermometer, constant pressure addition funnel, ice-water bath cooling and reflux condenser.

[0030] First mix 650 grams of dimethyldichlorosilane and 1500 grams of methyltrichlorosilane to prepare mixed monomers.

[0031] Add 1200 g of water into the reactor, and after cooling to 0-25°C, add the above-mentioned mixed monomers into the constant-pressure feeding funnel, and slowly add the monomers dropwise. Control the reaction temperature below 25°C, add the mixed monomers dropwise in 3 hours, and keep warm at 0-25°C for 3 hours after the addition. After the reaction, 1200 g of butyl acetate was added for extraction x 3 times, the extracts were combined, washed with water 400 g x 3 times, dried by adding 120 g of anhydrous sodium sulfate for 2 h, and the desiccant was removed by filtration.

[0032] The filtrate was distilled off under reduced pressure at 50° C. and a vacuum of ...

Embodiment 2

[0043] 1. Preparation of fluorosilicone resin

[0044] The reactor is equipped with mechanical stirring, thermometer, oil bath heating, water separator and reflux condenser.

[0045]120 grams of cyclohexane, 45 grams of silicone resin and 70 grams of fluororesin (fluororesin 212 purchased from Wuxi Wanbo Paint Chemical Co., Ltd., with a carboxyl content of 3.5%) were sequentially added to the reactor. Stir to dissolve evenly. After adding 1.1 g of dibutyltin dilaurate and 2.8 g of glycidoxypropylmethyldimethoxysilane, the temperature of the reaction solution was raised to 70° C. and refluxed for water separation for 8 hours.

[0046] After the reaction ended, the reaction was stopped, and 4.5 grams of water were separated out. The reaction solution was distilled off cyclohexane under reduced pressure at 50°C and a vacuum of 10 mmHg to obtain 112 g of a colorless viscous fluorosilicone resin product with a yield of 97%.

[0047] 2. Coating agent for fabric finishing

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com