Method for quickly reducing temperature and pressure of runway reaction system

A technology of runaway reaction and reaction system, applied in the direction of pressure vessels used in chemical processes, etc., can solve the problems of material loss, discharge process, production process interruption, etc., and achieve the effect of stable use and lower temperature and pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention discloses a method for rapidly reducing the temperature and pressure of an out-of-control reaction system. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be described in detail below in conjunction with specific examples.

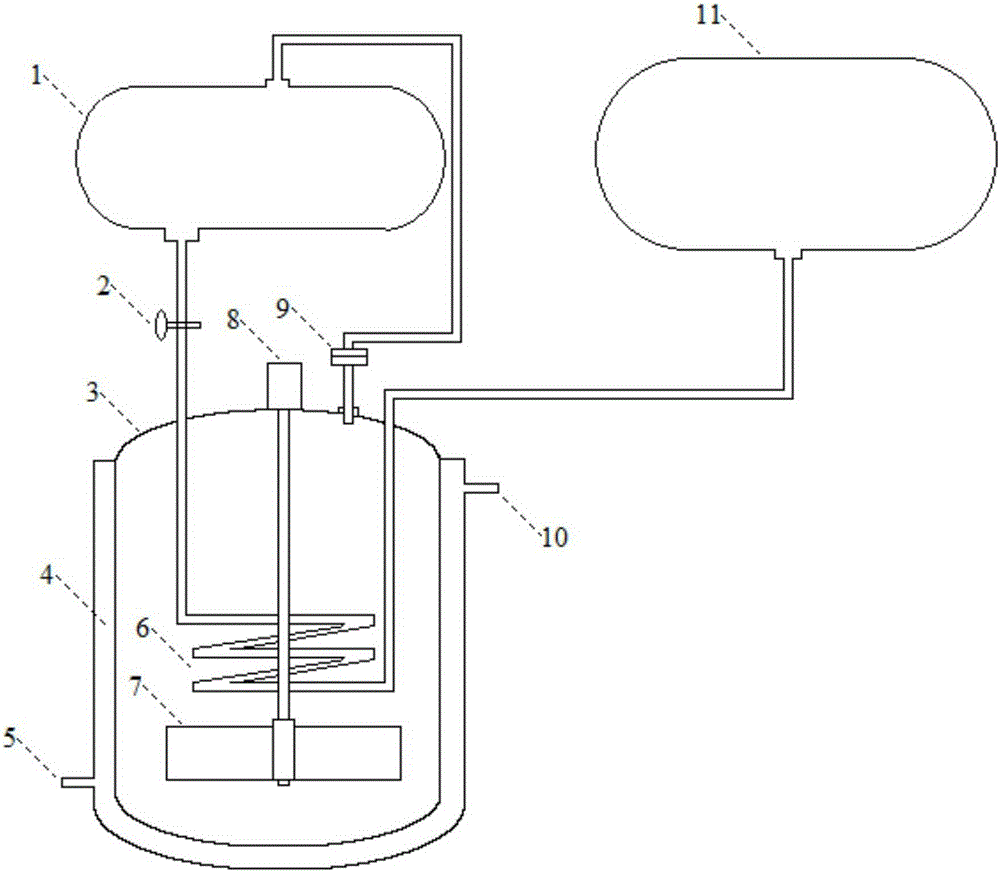

[0023] First, the device used in the method of the present invention is described in detail, as figure 1 As shown, the device of the present invention includes a reaction tank 3, a storage tank one 1 and a storage tank two 11, the reaction tank 3 is used to place reaction materials, and the reaction materials react in the reaction tank 3, and low-temperature raw materials are placed in the storage tank one 1 Solvent or cooling solvent is used to process the high temperature and high pressure situation generated in the reaction tank 3, and it cools the reaction tank by cooling. The specific structures of the reaction tank 3, storage tank one 1 and st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com