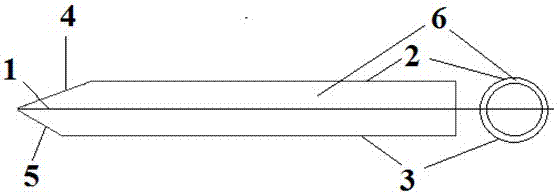

A push-bending forming device and method for continuous reverse-bending aluminum alloy pipe fittings

A technology for aluminum alloy and pipe fittings, which is applied in the field of push-bending forming devices for continuous reverse-bending aluminum alloy pipe fittings, can solve problems such as cross-sectional distortion of the second bending section of continuous reverse-bending, reduce the number of tests, suppress cross-sectional distortion, and shorten the The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

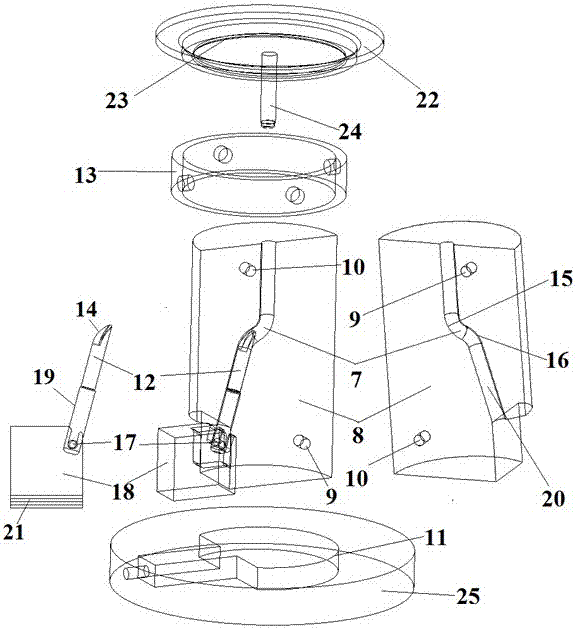

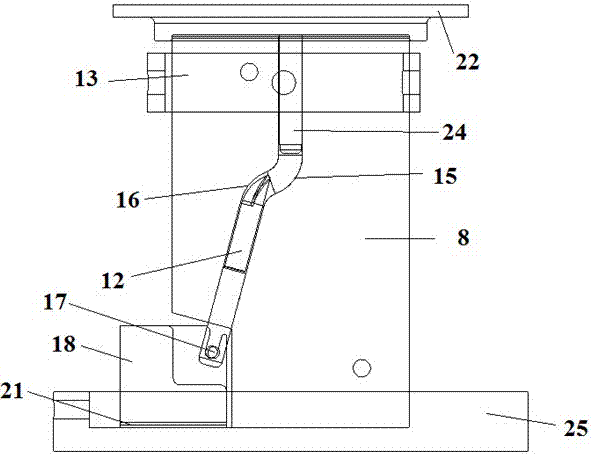

Method used

Image

Examples

Embodiment 1

[0046] The continuous reverse bending pipe fitting in this embodiment is a certain type of continuous reverse bending elbow, the material is 5A02 aluminum alloy, the outer diameter of the tube blank is 20mm, the wall thickness is 1mm, the length is 130mm, and the radius of the first and second bending sections of the continuous reverse bending is 25mm. , the angle between two straight pipelines is 15°. The entire pushing and bending process is carried out on a 100-ton press, and the pressing speed of the table is about 8mm / s. The finite element simulation results and push bending test results of continuous reverse bending aluminum alloy pipe fittings are as follows: Figure 5 As shown in the figure, it can be seen that both of them have formed a continuous curved geometric feature, and the cross-sectional distortion has been effectively suppressed to meet the product requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com