Assembly device and welding method using same

A pairing and flange technology, used in auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of inconvenient movement and adjustment, difficulty in pairing, low coaxiality, etc., and achieve high welding efficiency and labor intensity of workers. Low, the effect of ensuring the overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

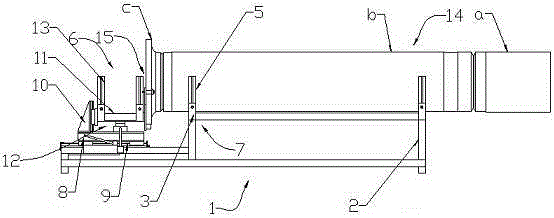

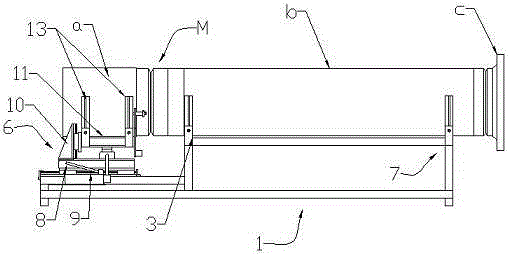

[0067] Example 1, such as figure 1 , figure 2 , image 3 As shown, a pairing device includes a base 1, and two sets of support bases 2 are fixedly connected to the middle of the base 1. The two sets of support bases 2 are provided with a support platform 7 for supporting a workpiece 14, and the support bases 2 are used to support The part with the largest weight or volume in the workpiece is generally an intermediate pipe.

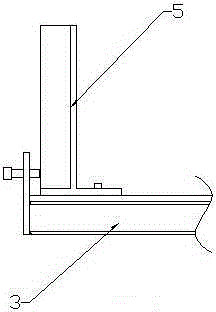

[0068] The support platform 7 is a support beam 3 or a support plate. When the support platform 7 is a support beam 3, the number of support beams 3 is at least two.

[0069] The upper end faces of the supporting beam 3 and the bottom of the workpiece 14 are flush with each other and maintain the same flatness.

[0070] One side of the upper end surface of the support beam 3 is provided with at least two first fixed plates, and the other side of the upper end surface of the support beam 3 is provided with at least two first fixed adjustment plates 5, ...

Embodiment 2

[0090] Example 2, such as Figure 6 As shown, a pairing device includes a base 1, and two sets of support bases 2 are provided in the middle of the base 1, wherein one set of support bases 2 is fixedly connected with the base 1, and the other set of support bases 2 passes through the third guide rail 21 and The sliding seat 22 is slidingly connected with the base 1, the supporting seat 2 is fixedly connected with the sliding seat 22, the third guide rail 21 is fixed on the base 1, the sliding seat 22 is slidingly connected with the third guiding rail 21, and the two sets of supporting seats 2 are equipped with The support device for the workpiece 14, the support seat 2 is used to support the part with the largest weight or volume in the workpiece, which is generally the middle pipe.

[0091] The support platform 7 is a support beam 3 or a support plate. When the support platform 7 is a support beam 3, the number of support beams 3 is at least two.

[0092] The upper end faces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com