Grinding process for container for high-purity ultra-pure electronic chemical product

A technology of electronic chemicals and grinding technology, which is applied in the direction of machine tools, grinding machines, manufacturing tools, etc., which are suitable for grinding the edge of workpieces. It can solve the problems of low inner wall finish, poor product quality, and difficult to completely remove substances, and achieve high inner wall finish. , Good grinding effect, fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

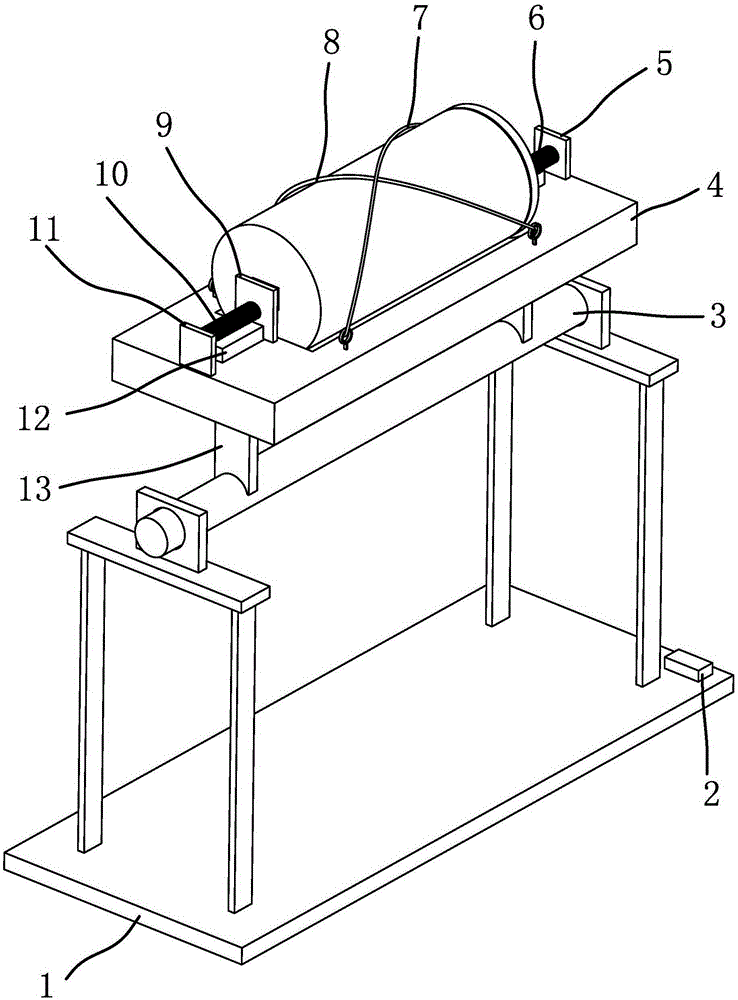

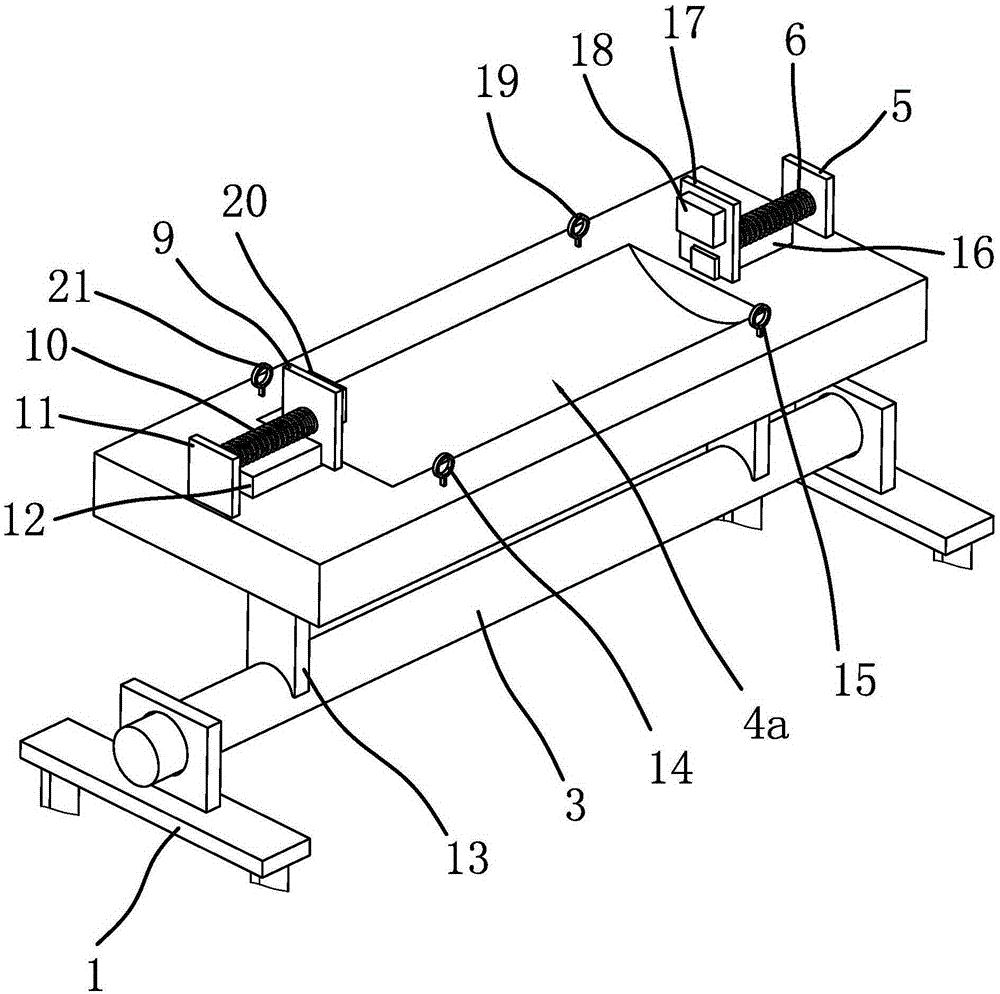

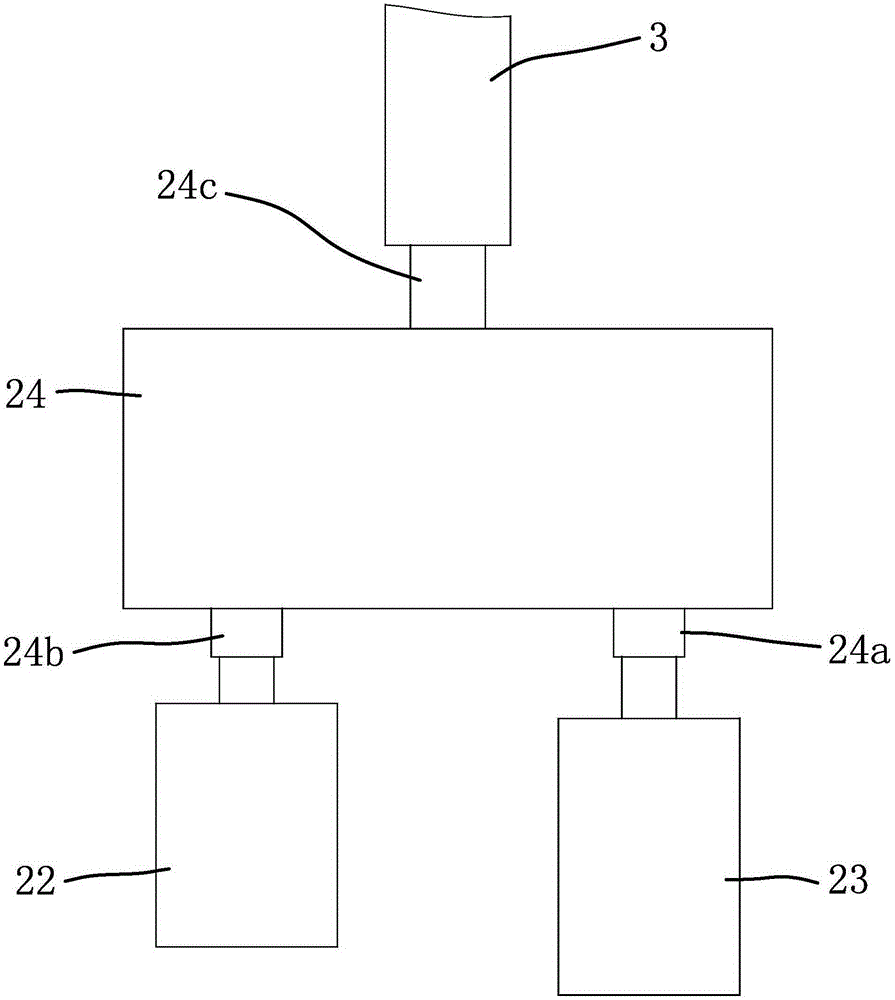

[0041] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0042] The grinding process of the container for high-purity and ultra-pure electronic chemicals includes the following steps: a. preparing the container to be ground; Go to the grinder, turn on the grinder for 10-15 hours, the coarse grinding time can be 10, 12 or 15 hours; make the coarse abrasive roll in the container, so as to coarsely grind the inner wall of the container; c, the first cleaning : the coarse abrasive in the container is poured out, and the inner wall of the container is cleaned by the cleaning device, so that the coarse abrasive is completely separated from the container; d, drying for the first time: using the gas drying device to dry the container; e, fine grinding: Load an appropriate amount of fine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com