Connecting structure for motorcycle plastic covering parts

A technology of plastic covering and connecting structure, used in bicycle accessories, weather guards, transportation and packaging, etc., can solve problems such as reduced work efficiency, damage, unsightly appearance, etc., to improve production efficiency, reduce assembly difficulty, and facilitate assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

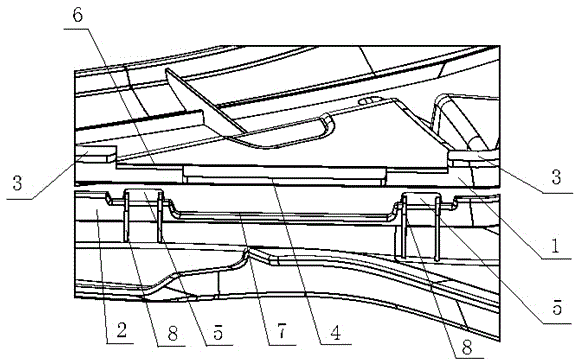

[0013] Such as figure 1 As shown, a connection structure of a motorcycle plastic cover in this specific embodiment includes a connection block I1 located on the cover I and a connection block II2 located on the cover II, the connection block I1 and the The abutment surface of the connection block II2 is fixedly connected with two plug-in blocks I3 and II4 arranged up and down and extending towards the direction of the connection block II, and the abutment surface of the connection block II2 and the connection block I1 There is an insert block III5 extending towards the connecting block I1 in fixed connection, the insert block III5 is located between the insert block I3 and the insert block II4 up and down, and the connecting block I1 is equipped with a The socket I6 where the plug block III5 is inserted, and the socket II7 that allows the plug block II4 to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com