A silicon-based flame retardant

A flame retardant, silicon-based technology, used in the field of flame retardants, can solve the problems of difficult interface formation and bonding, poor compatibility with polymers, poor compatibility, etc., to improve thermal stability and surface activity. , the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

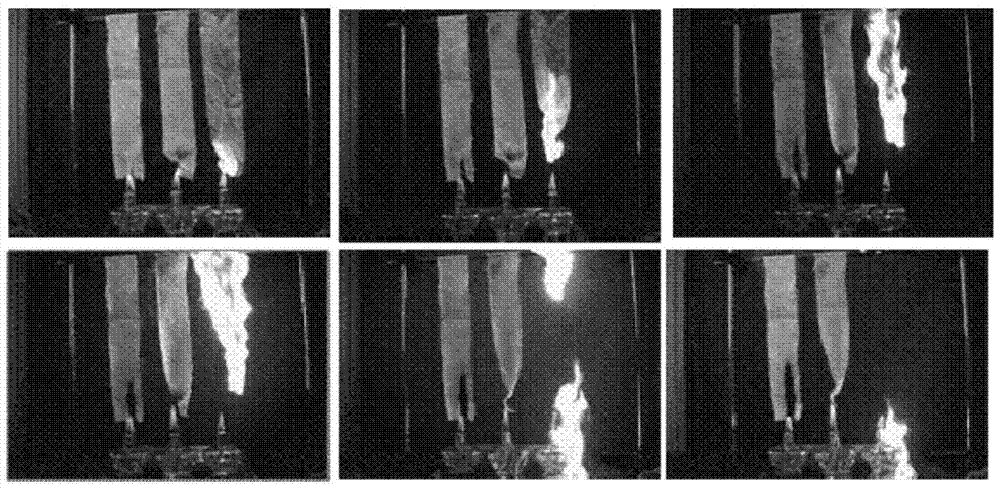

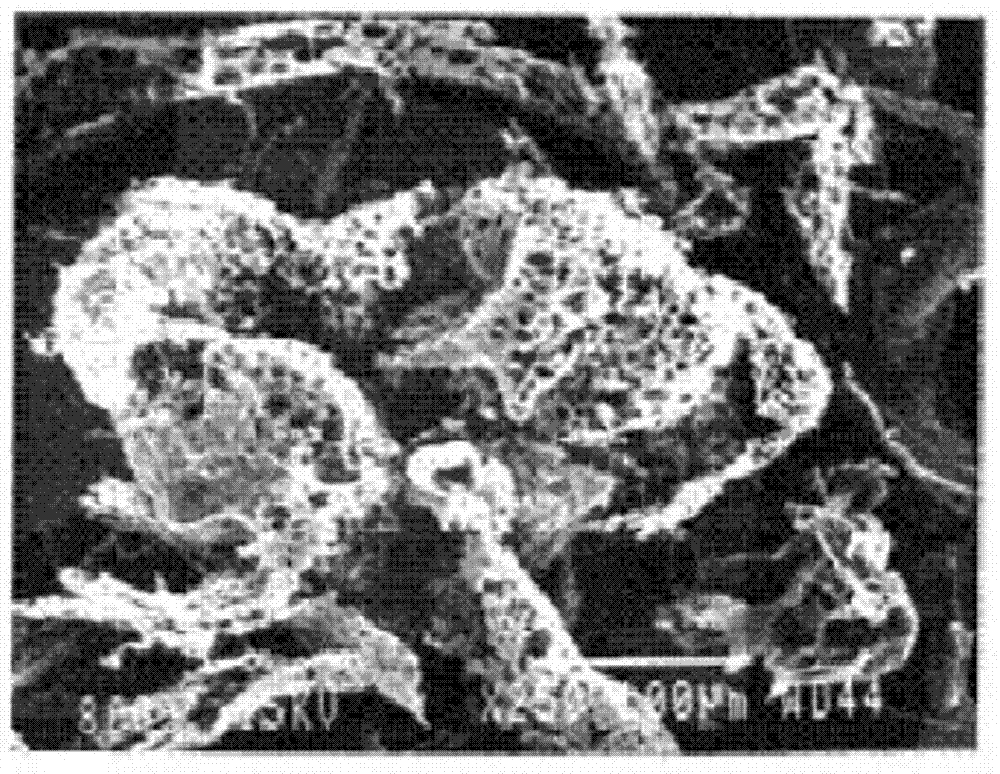

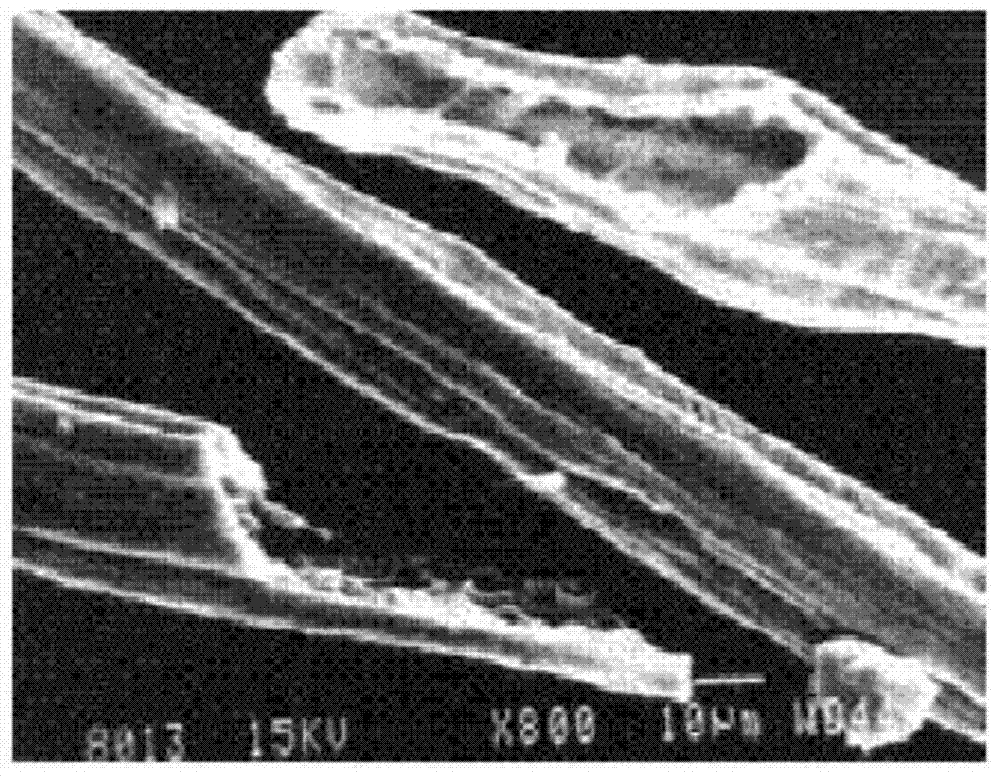

Image

Examples

Embodiment 1

[0029] Sodium silicate with a modulus of 1.4 is used to compound with aluminum hydroxide, sodium metaborate, ammonium polyphosphate and ammonium molybdate according to the compounding ratio of 48:2:1:1:0.3 to obtain a silicon-based flame retardant.

Embodiment 2

[0031] Sodium silicate with a modulus of 1.8 is used to compound with aluminum hydroxide, sodium metaborate, ammonium polyphosphate and ammonium molybdate according to the compounding ratio of 500:3:3:1:0.6 to obtain a silicon-based flame retardant.

Embodiment 3

[0033] Use the sodium silicate of modulus 1.8, carry out surface modification first, mix with aminopropyltriethoxysilane, the usage amount of aminopropyltriethoxysilane is 1.5wt% of described sodium silicate, then It is compounded with aluminum hydroxide, sodium metaborate, ammonium polyphosphate and ammonium molybdate according to the compounding ratio of 500:3.5:1.5:1:1 to obtain a silicon-based flame retardant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com