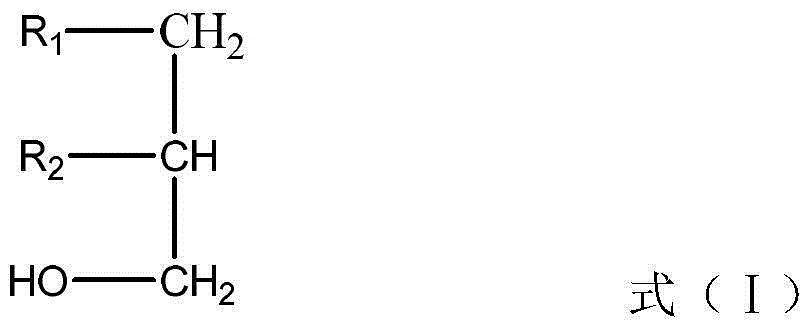

Lubricant composition for glass fiber reinforced engineering plastic and preparation method thereof

A technology of lubricant composition and engineering plastics, applied in the field of lubricant composition, to achieve the effect of strong versatility and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

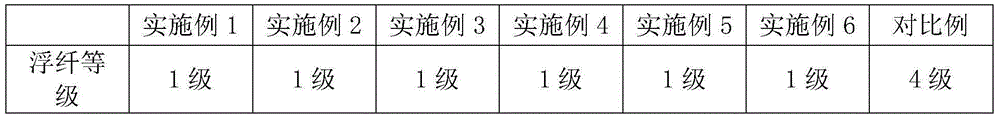

Examples

Embodiment 1

[0034] In the reaction kettle, put 100kg component A-glyceryl monostearate, 100kg component B-pentaerythritol tetrastearate, 50kg component C-stearyl polydimethylsiloxane (Guangdong standard silicone Fluorine New Material Co., Ltd., brand name is SF-233), using heat transfer oil to heat to 70 ℃ ~ 85 ℃, after the material is completely melted, then enter the rotary steel belt condensation granulator for granulation, and the particle size is about 6mm pellet finished product.

Embodiment 2

[0036] In the reactor, put 50kg component A-glycerol monolaurate, 100kg component B-pentaerythritol tetrapalmitate, 20kg component C-C 20-40 Alkyl polydimethylsiloxane (manufactured by Guangdong Biaomei Silicon Fluorine New Material Co., Ltd., the brand name is SF-240), heated to 70 ℃ ~ 85 ℃ with heat transfer oil, after all the materials are melted, then enter the rotary steel Granulate in a condensing granulator to obtain a finished product with a particle size of about 6mm.

Embodiment 3

[0038] In the reaction kettle, put 50kg component A-glyceryl monostearate, 50kg component B-pentaerythritol tetrapalmitate, 30kg component C-C 20-40 Alkyl polydimethylsiloxane (manufactured by Guangdong Biaomei Silicon Fluorine New Material Co., Ltd., the brand name is SF-240), heated to 70 ℃ ~ 85 ℃ with heat transfer oil, after all the materials are melted, then enter the rotary steel Granulate in a condensing granulator to obtain a finished product with a particle size of about 6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com