Air inflow adjusting structure of solid propellant rocket engine

A solid impulse engine and air intake adjustment technology, which is applied in the direction of machines/engines, mechanical equipment, jet propulsion devices, etc., can solve the problem of small adjustment range, achieve wide adjustment range, improve thrust and maneuverability, and flexibly adjust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

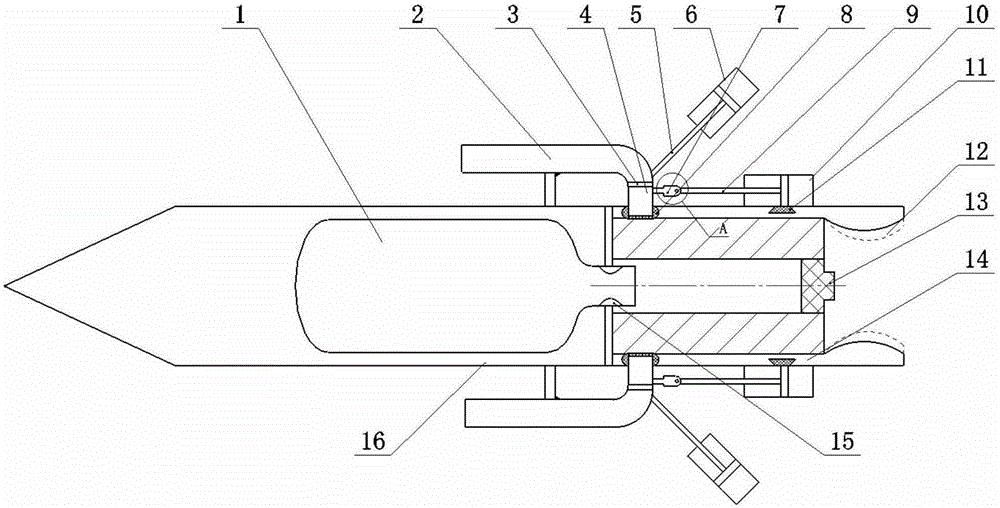

[0021] This embodiment is an air intake regulating structure of a solid impulse engine.

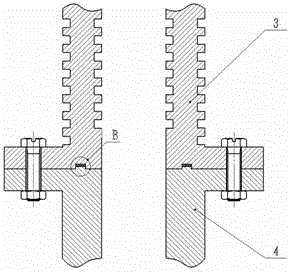

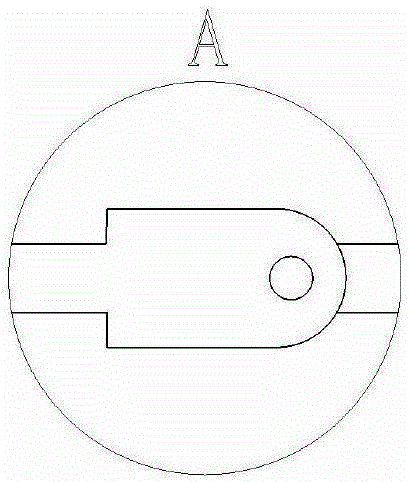

[0022] refer to Figure 1 to Figure 8 , the air intake adjustment structure of the solid impulse engine is composed of the solid impulse engine and the intake adjustment structure. The gas generator 1 of the solid impulse engine is fixed in the engine casing 16 and installed at the front of the engine combustion chamber 14. The solid charge Placed in the engine combustion chamber 14, the igniter 13 is installed in the engine combustion chamber 14 and fixed in the round hole at the end of the solid charge, near one end of the tail nozzle 12, the gas generator nozzle 15 and the igniter 13 are coaxially installed.

[0023] The air intake adjustment structure includes an air inlet fixed section 2, an air inlet adjustable section 4, a flexible connecting section 3, a first connecting rod 5, a second connecting rod 9, an outlet reversing ball 8, an actuating connecting rod 7, a second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com