Self-pressurizing device for automotive liquefied natural gas cylinder

A liquefied natural gas, self-pressurization technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as pressure drop in the bottle, no emergency shut-off valve device protection, and small flow rate of the vaporizer , to stabilize the pressure inside the gas cylinder, reduce heat leakage, and improve the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

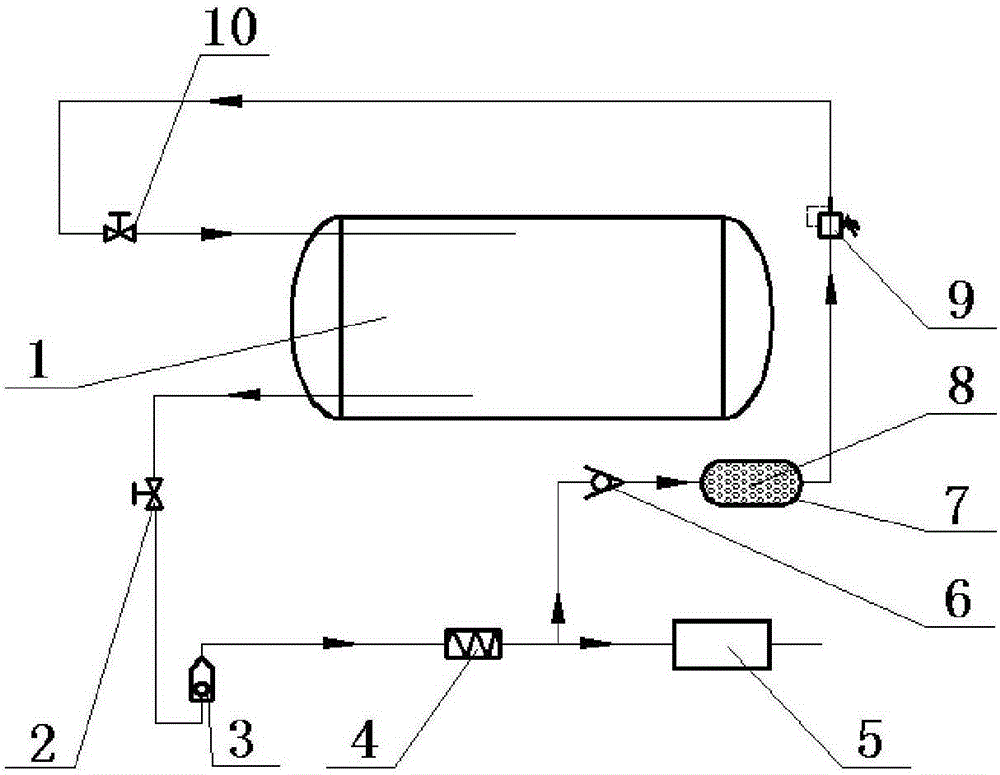

[0020] A self-pressurizing device for liquefied natural gas cylinders for vehicles, such as figure 1 Said, including vehicle liquefied natural gas cylinder 1, liquid outlet shut-off valve 2, emergency shut-off valve 3, carburetor 4, one-way valve 6, adsorption gas storage device 7, adsorbent 8, booster valve 9, gas phase shut-off valve 10 .

[0021] The liquefied natural gas cylinder 1 for vehicles communicates with the liquid outlet stop valve 2 and the gas phase stop valve 10 through pipelines.

[0022] Liquid outlet cut-off valve 2, emergency cut-off valve 3, vaporizer 4, one-way valve 6, adsorption gas storage device 7, booster valve 9, and gas phase cut-off valve 10 are sequentially connected in series on the pipeline.

[0023] The carburetor 4 communicates with the one-way valve 6 and the engine system 5 through pipelines respectively.

[0024] The adsorption gas storage device 7 is filled with an adsorbent 8 .

[0025] The working principle of the present invention i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com