A Visualized Liquid-liquid Two-phase Flow Loop Experimental Device

An experimental device and loop technology, which is applied to measurement devices, fluid dynamics tests, instruments, etc., can solve the problems of large parameter variation range, huge differences in measured data, and inability to compare with each other, so as to reduce workload, large utilization rate, Full-featured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and implementation examples.

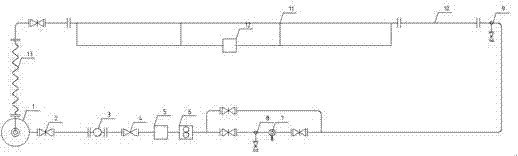

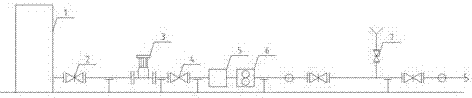

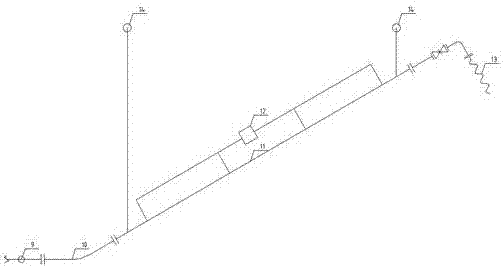

[0020] see figure 1 , the loop experiment device consists of a liquid storage tank 1, an outlet valve 2, a centrifugal pump 3, a flow regulating valve 4, a temperature transmitter 5, a flow transmitter 6, a filling system 7, a first blowdown valve 8, and a second blowdown valve The valve 9, the acrylic elbow 10, the upwardly inclined pipeline 11, the differential pressure transmitter 12, and the return system 13 are sequentially connected by flanges. The pipe diameter of the loop test device is 50mm, and the materials are galvanized steel pipe, acrylic pipe and steel wire spiral hose. The design dimensions and functions of each part of the device are as follows:

[0021] The size of the liquid storage tank 1 is a cylindrical steel barrel with a diameter of 323.9mm and a height of 1200mm. The bottom of the liquid storage tank is an inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com