Array substrate, manufacturing method thereof and liquid crystal display panel

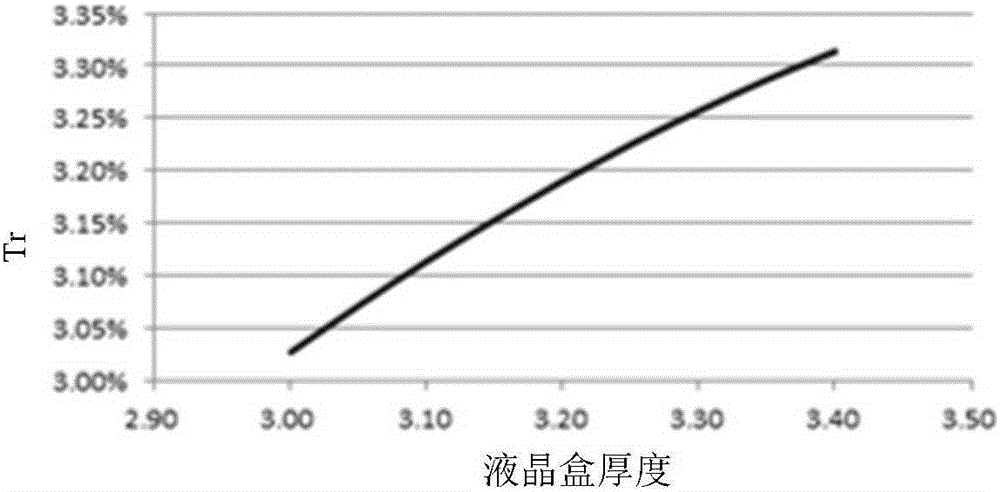

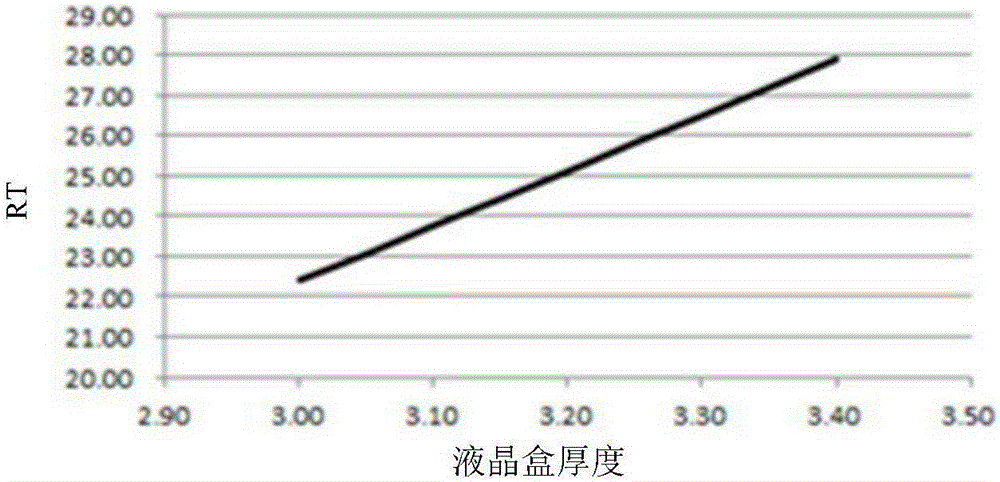

A liquid crystal display panel and array substrate technology, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of affecting the imaging quality of the panel and increasing the response time of the liquid crystal display panel, so as to improve the problem of large viewing angle deviation and response time Reduce and increase the effect of Tr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

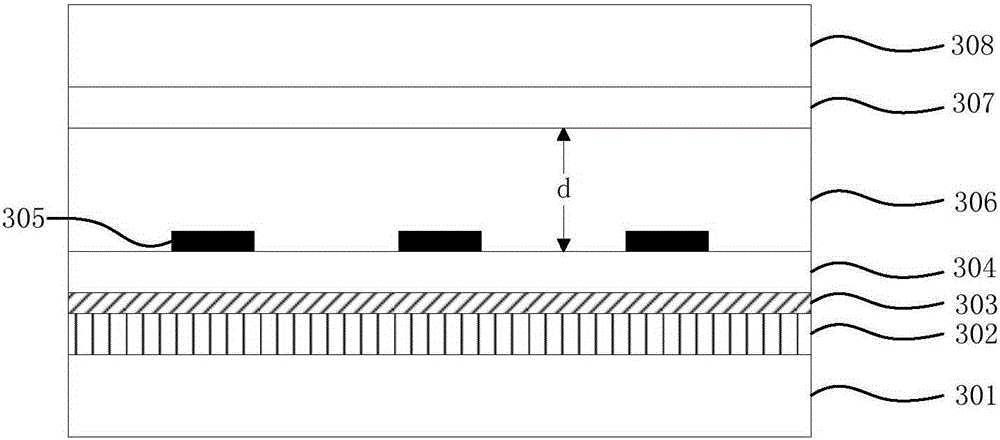

[0045] image 3 A schematic structural diagram of an existing FFS type liquid crystal display panel is shown.

[0046] Such as image 3 As shown, the existing liquid crystal display panel includes: an array substrate, a liquid crystal cell 306 and a CF substrate. Wherein, the array substrate includes: a lower substrate 301 , a first insulating layer 302 , a common electrode 303 , a second insulating layer 304 and a pixel electrode 305 . The CF substrate includes a color filter 307 and a glass substrate 308 . Wherein, the pixel electrode 305 is formed on the second insulating layer 304 . For the liquid crystal cell 306 , its thickness is the distance d between the color filter 307 and the second insulating layer 304 . For the existing FFS liquid crystal display panel, the thickness d of the liquid crystal cell is also its effective thickness. The lower substrate 301 includes structures such as a light-transmitting liner, an insulating layer, and scan lines and / or data line...

Embodiment 2

[0065] Figure 7 A schematic structural diagram of an existing IPS liquid crystal display panel is shown.

[0066] Such as Figure 7 As shown, the existing liquid crystal display panel includes: an array substrate, a liquid crystal cell 704 and a CF substrate. Wherein, the array substrate includes: a lower substrate 701 , an insulating layer 702 and an electrode layer 703 . The CF substrate includes a color filter 705 and a glass substrate 706 . Wherein, the electrode layer 703 is formed on the insulating layer 702 . For the liquid crystal cell 704 , its thickness is the distance d between the color filter 705 and the insulating layer 702 . For the existing IPS liquid crystal display panel, the thickness d of the liquid crystal cell is also its effective thickness.

[0067] The existing liquid crystal display panel increases the transmittance Tr of the panel by increasing the thickness of the liquid crystal cell 704 , however, the increase in the thickness of the liquid c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com