Vacuum frame and sealing method for EUV (extreme ultraviolet) lithography device

A lithography equipment and frame technology, which is applied to microlithography exposure equipment, photolithographic process exposure devices, etc., can solve the problems of low reliability and complex structure, and achieves small space, flexible manual operation, and reusable gas. dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

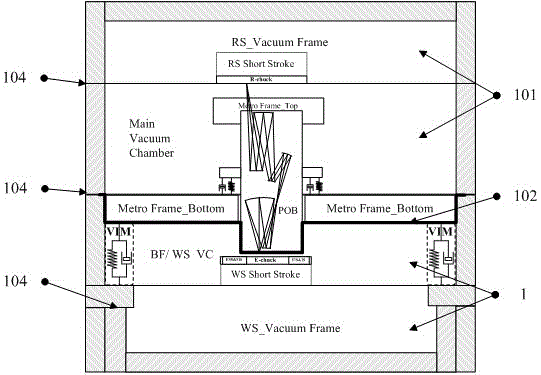

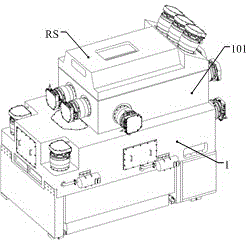

[0028] figure 1 A vacuum frame of a lithographic apparatus according to Embodiment 1 of the present invention is schematically shown. The mask part (vacuum degree requirement is 10-7~10-9mbar) and the silicon wafer exposure part (vacuum degree requirement is 10-5~10-7mbar) require different vacuum degrees, so the main substrate is used as the interface to The vacuum chamber is divided into a main vacuum chamber (MainVacuumChamber) 101 and a workpiece table vacuum chamber (WSVacuumChamber) 1, and the dynamic balance of high vacuum is realized by means of pumping and exhausting respectively. Several sealing surfaces 104 are also included between each vacuum chamber. The main substrate serves as the interface 102 between the main vacuum chamber 101 and the vacuum chamber 1 of the workpiece table.

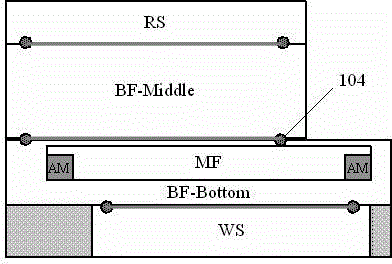

[0029] The layout diagram of the vacuum syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com