System used for controlling machine production data and method thereof

A production data and monitoring system technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of finding, error, lack of validity and accuracy of parameter range, etc., to expand the range of data parameters, improve Effective and feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

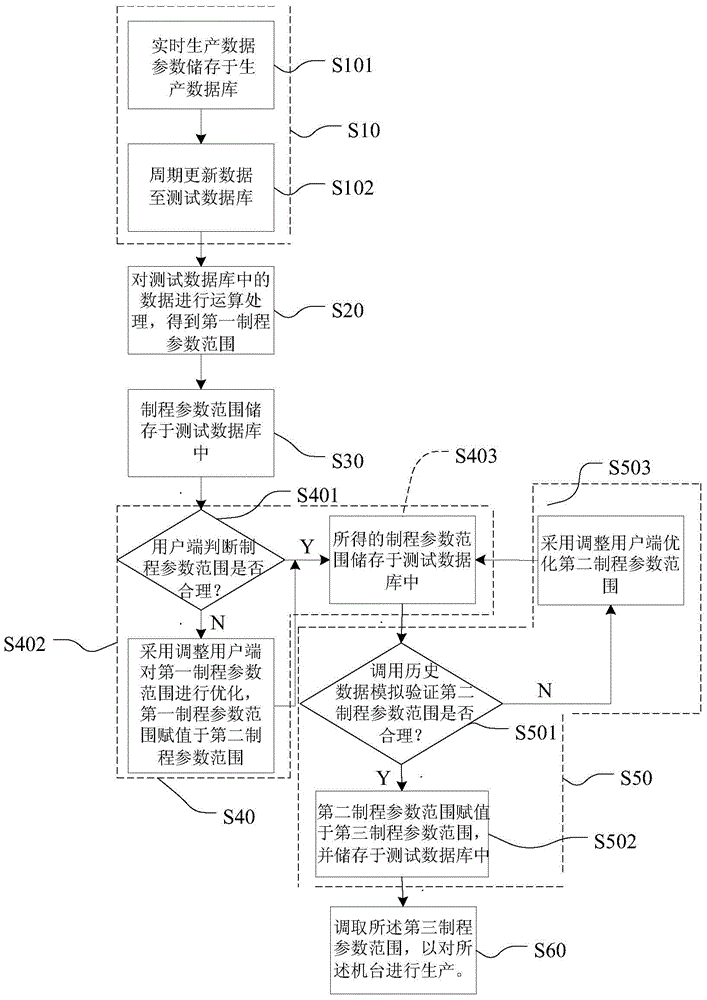

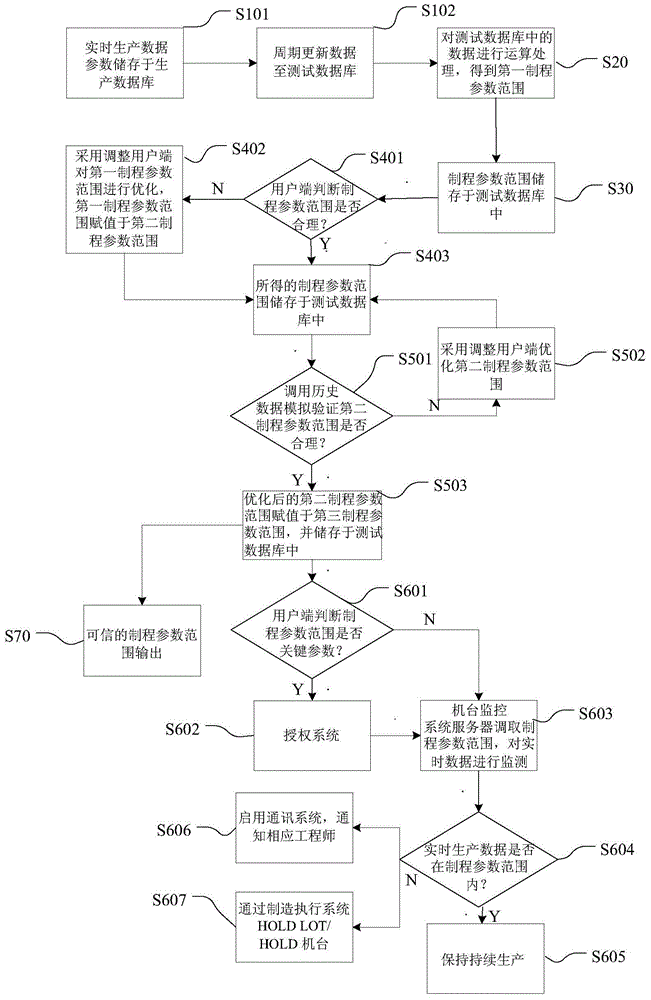

[0062] The system and method of the present invention also involve changes in the range of process parameters in the actual production environment that must be authorized before they can be used in actual production, and whether the range of changes in these data parameters is within the controllable or beyond the controllable range. The abnormal rate of the process parameter range and the appropriate measures for different abnormal rates need to be signed off to form a systematic production management.

[0063] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

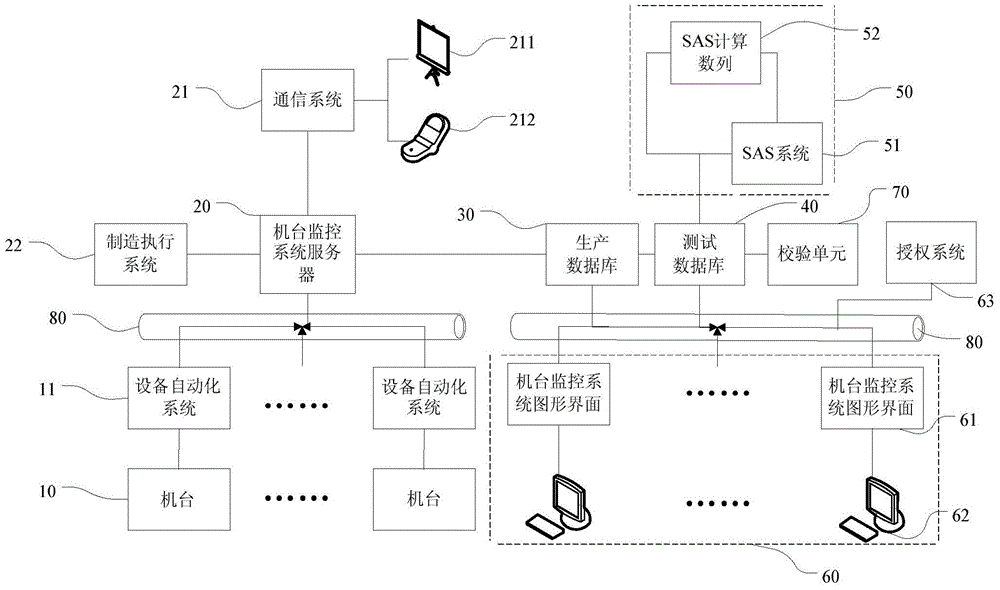

[0064] figure 1 It is an architecture diagram showing a system for managing and controlling production data of a semiconductor machine applied in an embodiment of the present invention. The system described in the embodiment of the present invention first includes several machines (such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com