Transformer for welding machine

A transformer and welding machine technology, which is applied in the direction of transformer/inductor cooling, transformer/inductor magnetic core, transformer/inductor parts, etc., can solve the problems of iron core quality degradation, accelerated transformer aging, and increased magnetic induction intensity. Achieve the effect of convenient operation, convenient disassembly and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

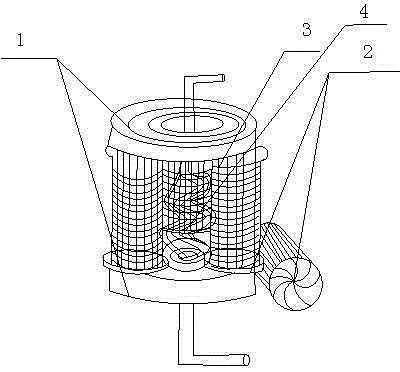

[0015] like figure 1 As shown, the present invention includes a yoke 1, a plurality of stems 2, a coil 3 and a water circulation pipe 4. The yoke 1 is rolled from a strip-shaped cold-rolled silicon steel sheet, and a plurality of stems are located between two yokes 1. Between two yoke irons 1 and multiple core columns are fixed by bolts; the water circulation pipe 4 penetrates from the center of one yoke iron and spirally extends downward through the cavity surrounded by multiple core columns 2 , passing through the middle of another yoke.

[0016] The transformer is sleeved on the core column through a coil, and the yoke is connected to three iron core columns to close the magnetic circuit, and the yoke is rolled from a strip-shaped cold-rolled silicon steel sheet. Bolts are fixed. When the transformer needs to be disassembled, only need to remove the corresponding bolts to realize the disassembly of the iron core column and the yoke iron, then replace the faulty core colum...

Embodiment 2

[0018] This embodiment is preferably as follows on the basis of Embodiment 1: the water circulation pipeline 4 includes a helically coiled main pipe and a plurality of helically coiled branch pipes connected to the main pipe. The design of more branch pipes can allow more water to stay in the cavity formed by multiple stems and take away more heat.

[0019] Each iron core column 2 is formed by lamination of silicon steel sheet inserts with an involute cross-section. This arrangement can avoid curling of the core post during the connection and fixation process with the yoke iron.

[0020] There are three stem pillars 2, and the three stem pillars are triangularly distributed. Improve the stability of the transformer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com