Method of dispersing arc to improve service life of generator and arc plasma generator

An arc generation and generator technology, applied in the direction of plasma, electrical components, etc., can solve the problems of complex structure and high maintenance cost of thermal plasma generators, and achieve the effects of improving life, reducing electrode ablation, and expanding the scope of application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

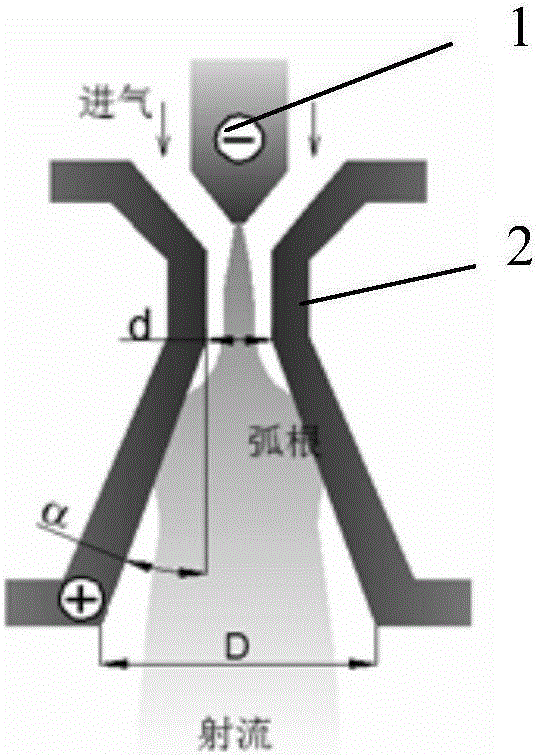

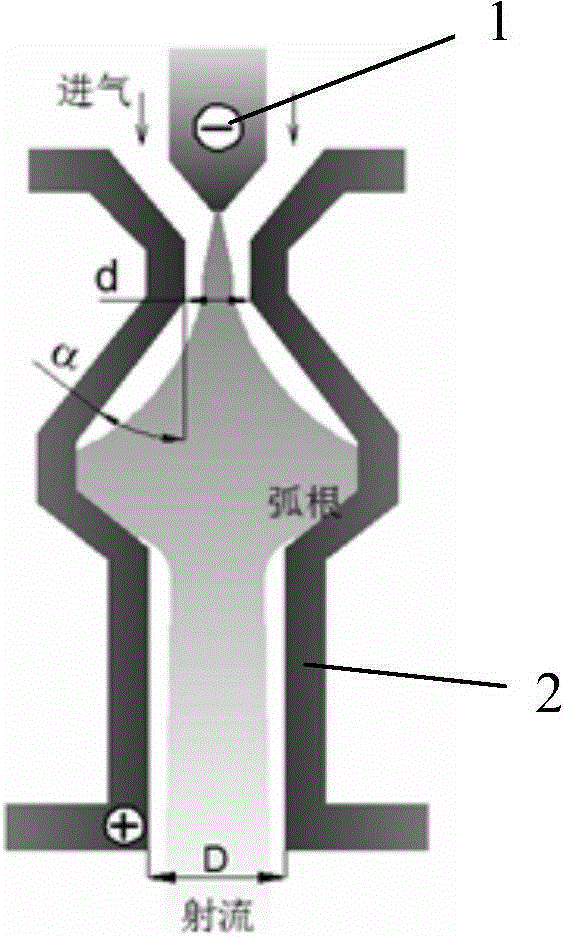

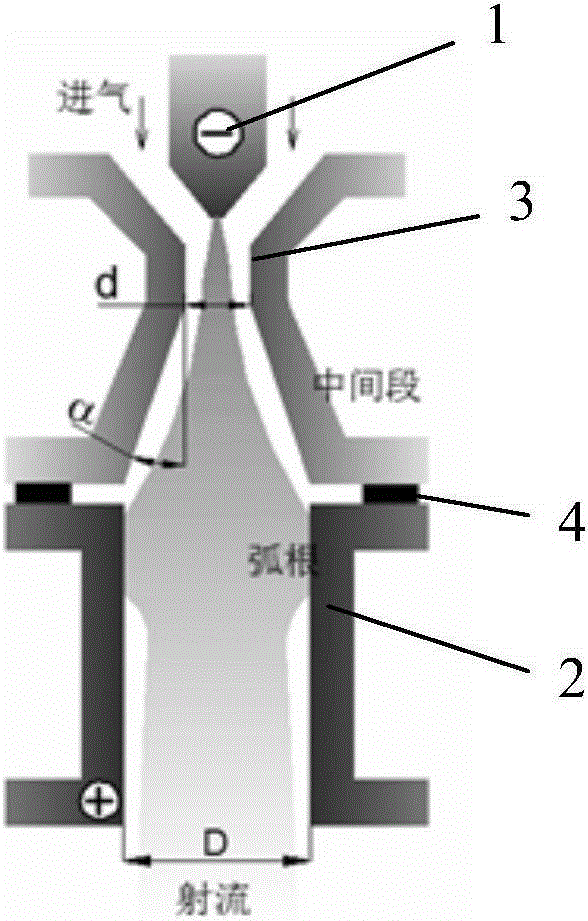

[0026] The basic idea of the invention is to disperse the arc into a state of lower current density in the channel away from the anode surface, ie to expand the arc discharge gas. From the perspective of the arc channel structure of the generator, the arc flows through the small-diameter confinement channel and the expansion structure channel that promotes the expansion and dispersion of the arc before attaching the anode. The expansion and dispersion of the arc reduces the current density of the arc in the electrode surface attachment area. Therefore, electrode ablation is reduced, and the expansion half angle of the pneumatic expansion structure channel is within 45 degrees.

[0027] figure 1 and 2 An arc plasma generator is given, including a cathode 1, and a confinement and expansion structure channel 2, and the confinement and expansion structure channel 2 is also an anode.

[0028] It is arranged downstream of the cathode along the arc transmission direction, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com