Method for improving copper-free hole metallization

A technology without copper holes and copper layers, which is applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems that affect the appearance and yield of printed circuit boards, cannot be cleaned, and are easy to gold, etc., to save palladium removal Effects of potion, improvement of cloaking problem, and improvement of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

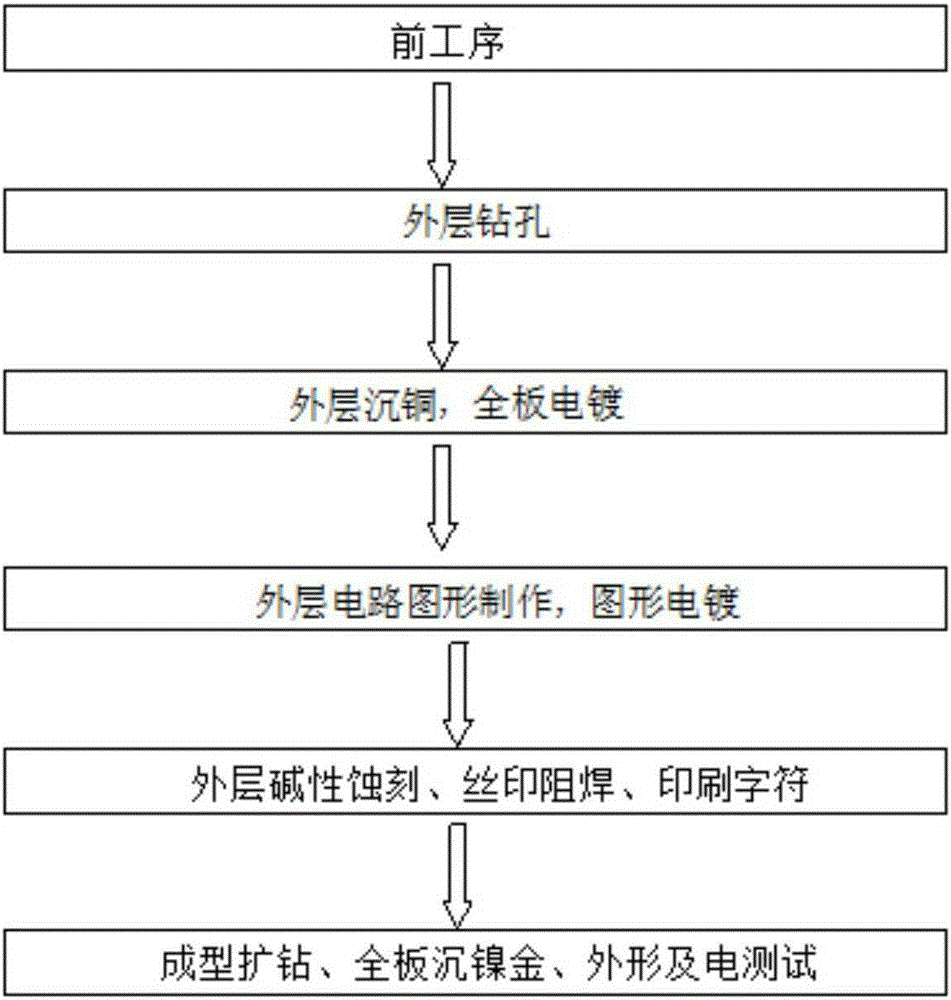

[0030] This embodiment provides a method for improving gold on copper-free holes, which includes the following steps:

[0031] S1. Pre-process: Carry out cutting of the circuit board substrate: cut out the core board according to the size of the imposition; inner layer graphic printing: complete the line exposure of the inner layer core board with a 6-grid exposure ruler, and have different thicknesses of the inner layer copper after development Etching out the circuit pattern of the inner core board; Lamination of the inner and outer layers: select appropriate lamination conditions according to the glass transition temperature of the sheet to carry out lamination of the inner core board and the outer copper foil;

[0032] S2. Drilling the outer layer. According to the board thickness, use the drilling data and use the drill to drill through holes and copper-free holes on the outer layer of the printed circuit board. The size of the copper-free hole requires that the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com