Flocculation concentration device with grille structure bodies and filtrate recycling tank with grille structure bodies

A technology of concentration device and structure, which is applied in the direction of filtration circuit, flocculation/sedimentation water/sewage treatment, filtration and separation, etc. It can solve the problems of low solid-liquid separation efficiency, slow propulsion speed, high water content, etc., and achieve growth flocculation reaction Time, increase the treatment capacity, reduce the effect of water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

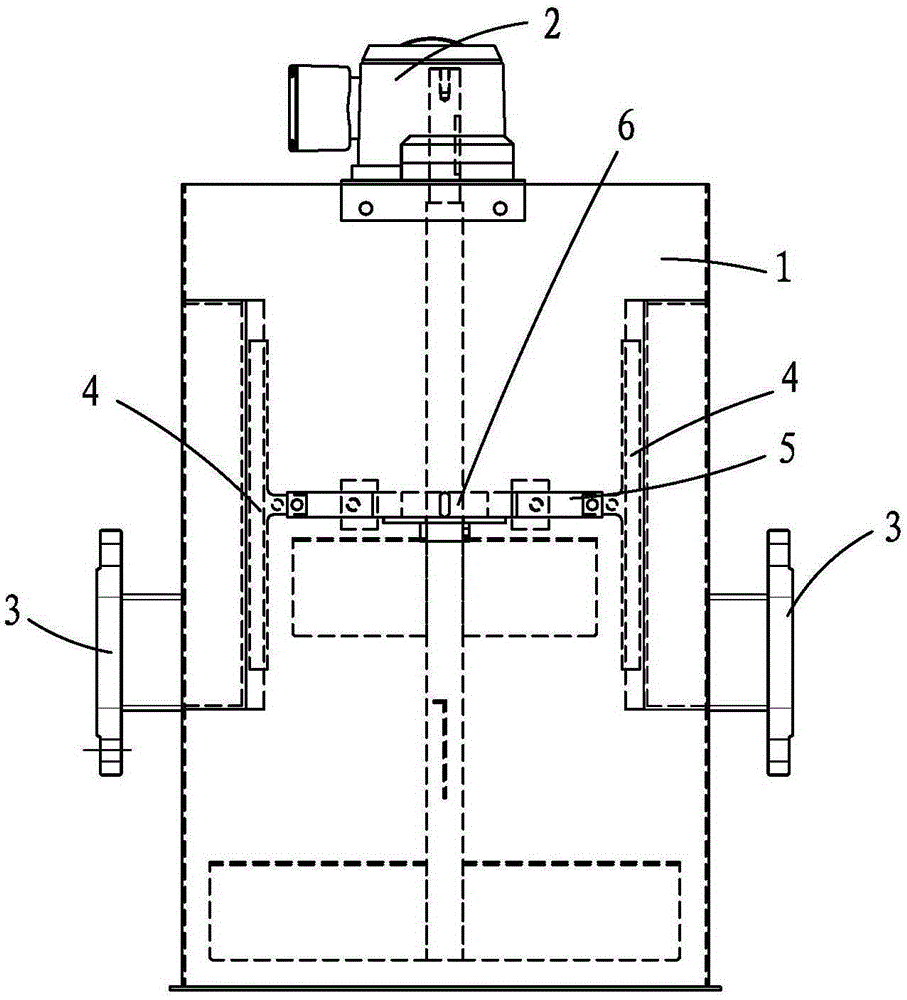

[0026] Such as figure 1 , 2 As shown in . and 3, a flocculation concentration device with a grid structure includes a flocculation mixing tank 1, a stirring device 2 is arranged in the flocculation mixing tank 1, and on two opposite tank walls of the flocculation mixing tank 1 A supernatant overflow port 3 is respectively provided, and a grid structure 4 is arranged at the supernatant liquid overflow port 3 .

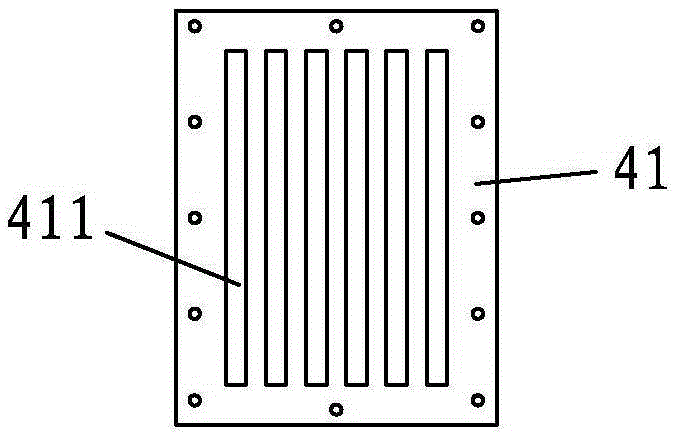

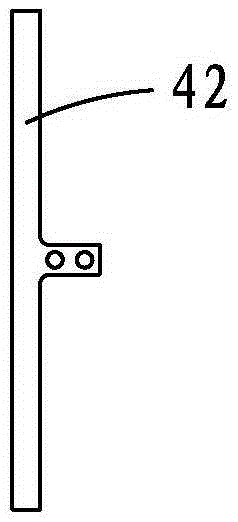

[0027] The grid structure 4 includes a fixed grid 41 and a plurality of grid bars 42, the fixed grid 41 is fixedly arranged at the supernatant overflow port 3 in the flocculation mixing tank 1, and the fixed grid The surface of the plate 41 is provided with a plurality of filter slits 411, and a grid bar 42 is arranged in each filter slit 411, and the grid bar 42 is connected to the stirring shaft of the stirring device 2 through a transmission rod 5 and an eccentric device 6. The eccentric device 6 on the stirring shaft drives the transmission rod 5 to make the grid ...

no. 2 example

[0030] Such as figure 2 , 3 , 4, a flocculation concentration device with a grid structure, including a flocculation mixing tank 1, a partition 7 is arranged in the flocculation mixing tank 1 to divide it into a flocculation reaction zone 11 and a concentration settlement zone 12; The height of the partition plate 7 is lower than the height of the flocculation mixing tank 1; the stirring device 2 is located in the flocculation reaction zone 11; the tank wall of the concentrated settlement zone 12 is provided with a supernatant overflow port 3 , a grid structure 4 is provided at the overflow port 3 of the supernatant liquid.

[0031] The grid structure 4 includes a fixed grid 41 and a plurality of grid bars 42, the fixed grid 41 is fixedly arranged at the supernatant overflow port 3 in the flocculation mixing tank 1, and the fixed grid The surface of the plate 41 is provided with a plurality of filter slits 411, and a grid bar 42 is arranged in each filter slit 411, and the ...

no. 3 example

[0037] Such as figure 2 , 3 , 5, a filtrate recovery tank 100 with a grid structure, the tank wall of the filtrate recovery tank 100 is provided with a grid structure 4.

[0038] The grid structure 4 includes a fixed grid 41 and a plurality of grid bars 42, the fixed grid 41 is fixedly arranged on the tank wall of the filtrate recovery tank 100, and the surface of the fixed grid 41 is provided with multiple Each filter slit 411 is provided with a grid bar 42 in each filter slot 411, and the grid bar 42 is driven by a driving device (not shown in the figure), thereby making the grid bar 42 move. The unblocked state of the filter slit 411 can be kept to avoid clogging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com