Method and device of high-effective flue gas demercuration for coal-fired power plant

A coal-fired power plant, high-efficiency technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of mercury saturation, increase the mercury removal capacity of wet desulfurization system, etc., achieve burden reduction and high promotion and application value , The effect of low installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

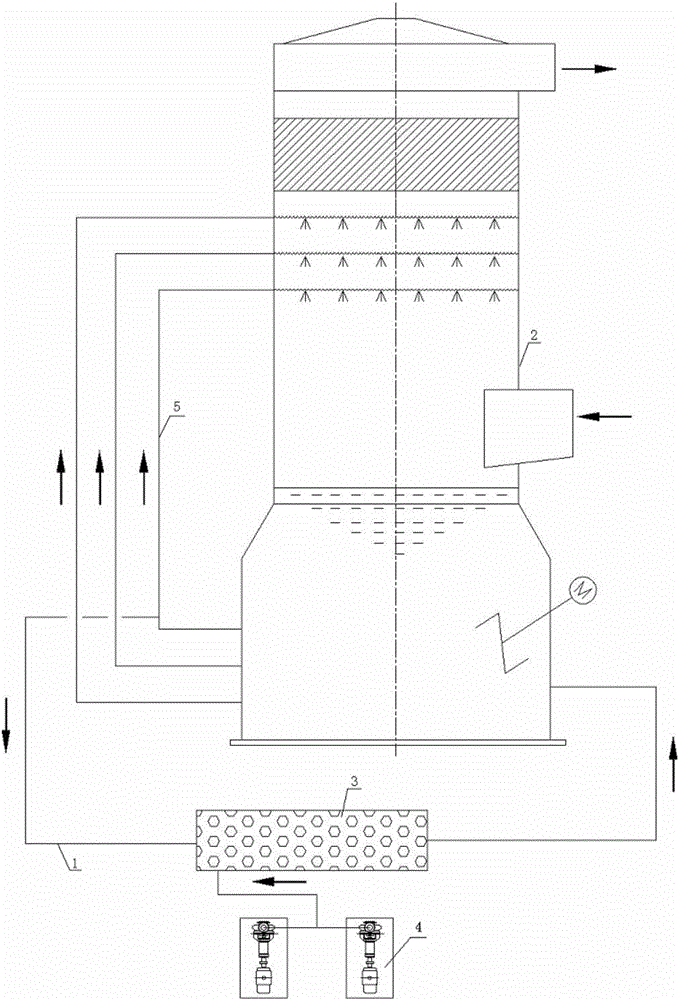

Image

Examples

Embodiment Construction

[0025] Working principle of the present invention:

[0026] Under the synergistic removal of existing environmental protection facilities, flue gas mercury can reach a lower emission level, and the general flue gas mercury concentration can be reduced to 0.015-0.03mg / Nm 3 .

[0027] However, through actual tests and research, it is found that unless activated carbon injection technology with high operating costs is used, when the flue gas mercury concentration is reduced to 0.003-0.005mg / Nm 3 , no matter what other measures are taken, the emission value cannot be further reduced. The reason is that, according to Henry's law, under isothermal and pressure conditions, the solubility of a certain gas in a solution is proportional to the equilibrium pressure of the gas on the liquid surface, that is, Pa=Kx,a·Xa. Where Pa is the gas phase partial pressure of the component, Kx,a is the pressure coefficient, and Xa is the concentration of the liquid phase component. It can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com