Method for activating carbon nanotube-supported palladium nanoparticle catalyst and application thereof

A technology of carbon nanotubes and palladium nanometers, which is applied in the field of new green and environmentally friendly activated carbon nanotube-loaded palladium nanoparticle catalysts, can solve the problems of insufficient proven reserves, waste, and low utilization rate, so as to reduce energy consumption and improve catalytic performance , the effect of simple application equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

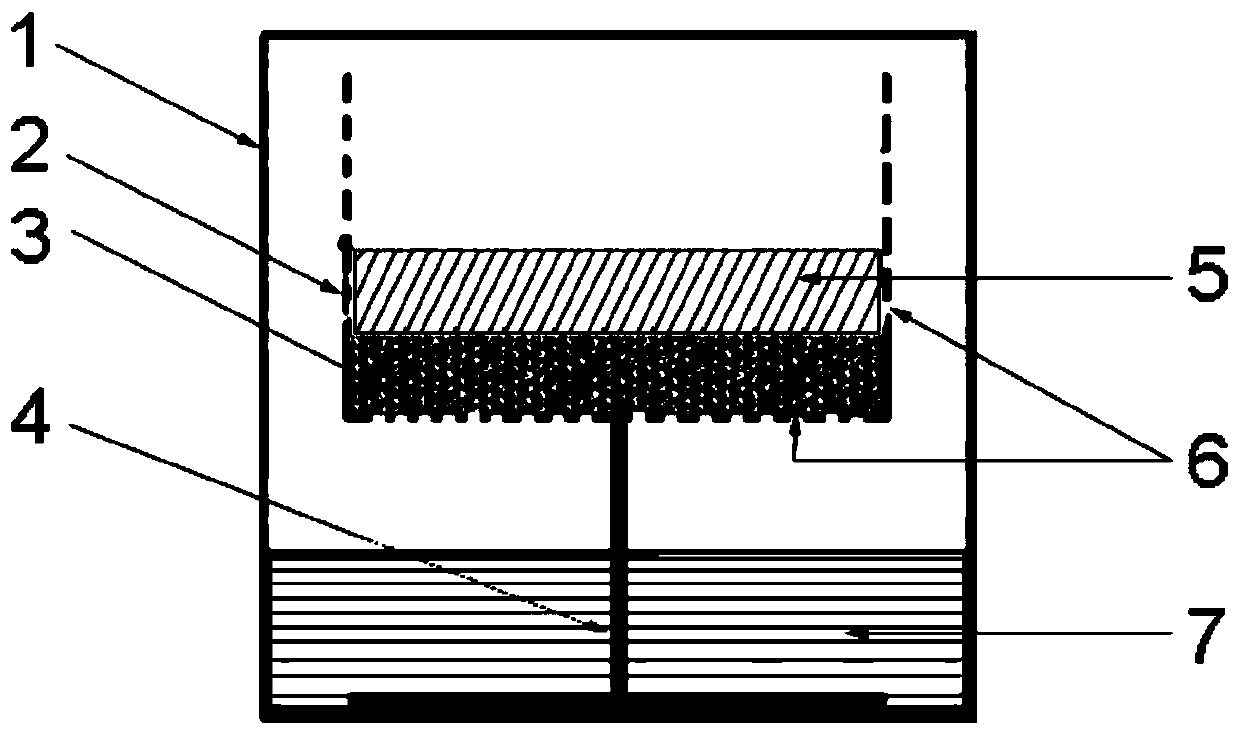

[0024] (1) Preparation of carbon nanotube-supported palladium nanoparticles catalyst

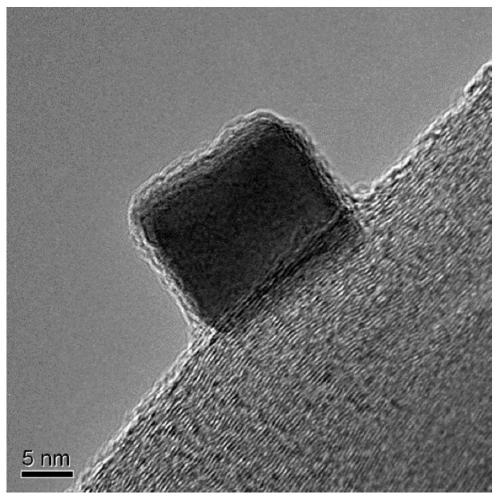

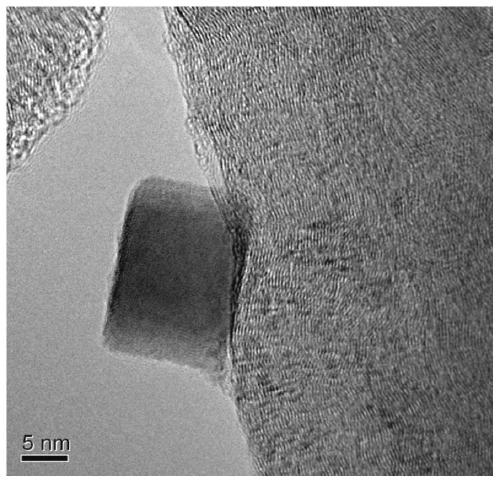

[0025] 1) Take 60mg of ascorbic acid, 105mg of PVP and 600mg of potassium bromide, add 8mL of distilled water to dissolve, stir to dissolve, put it in an oil bath at 80°C for 1 hour, then quickly add 3mL of Na 2 PdCl 4 Aqueous solution (contains Na 2 PdCl 4 57 mg), continued to react in an oil bath at 80°C for 3 h, centrifuged, and dried the product in a vacuum oven to obtain a bright black solid powder, namely palladium nanoparticles.

[0026] 2) Put 2 mL of palladium nanoparticle solution with a concentration of 1 mg / mL in a beaker, add absolute ethanol to dilute to 15 mL, sonicate for three minutes, and pour it into a titration funnel for use.

[0027] 3) Weigh 100mg of carbon nanotubes (LNT) into a 100mL round-bottomed flask, add 20mL of ethanol, and after ultrasonication for 8 minutes, start to drop the ethanol solution of palladium nanoparticles, keep the flow rate for 1-2 seconds ...

Embodiment 2

[0033] (1) Application of Activated Carbon Nanotube-supported Palladium Nanoparticle Catalysts in Suzuki Reaction

[0034] 1. Activation: The carbon nanotube-supported palladium nanoparticle catalyst prepared in Example 1 was placed in a container, and the method was the same as step (2) of Example 1, and treated at 60° C. for 4 hours.

[0035] 2. Mix 0.5853g of phenylboronic acid, 1.1057g of potassium carbonate, 40mL of aqueous ethanol (ethanol:water=5:3v / v), and 10mg of activated carbon nanotube-supported palladium nanoparticle catalyst, and mix them uniformly, and place them in an oil bath at 60°C After stirring for 10 minutes, 0.44 mL of bromobenzene was added to continue the reaction. A small amount of product was taken at 15, 25, 35 and 50 minutes respectively, and the reaction product was analyzed by GC. After 25 minutes of reaction, the conversion rate was 50%.

Embodiment 3

[0039] 1. Activation: The carbon nanotube-loaded palladium nanoparticle catalyst prepared in Example 1 was placed in a container, and the method was the same as step (2) of Example 1, and treated at 80° C. for 4 hours.

[0040]2. Mix 0.5853g of phenylboronic acid, 1.1057g of potassium carbonate, 40mL of aqueous ethanol (ethanol:water=5:3v / v), and 10mg of activated carbon nanotube-supported palladium nanoparticle catalyst, and mix them uniformly, and place them in an oil bath at 60°C After stirring for 10 minutes, 0.44 mL of bromobenzene was added to continue the reaction. A small amount of product was taken at 15, 25, 35 and 50 minutes respectively, and the reaction product was analyzed by GC. After 25 minutes of reaction, the conversion rate was 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com