Method for preparing graphene by continuous jet coating of liquid CO2 suspension of graphite powder

A technology of suspension and graphite powder, which is applied in the field of new material manufacturing, can solve the problems of small scale, dispersed human resources, and low level, and achieve the effect of simple application equipment, no production waste, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with specific embodiment the present invention is described in further detail:

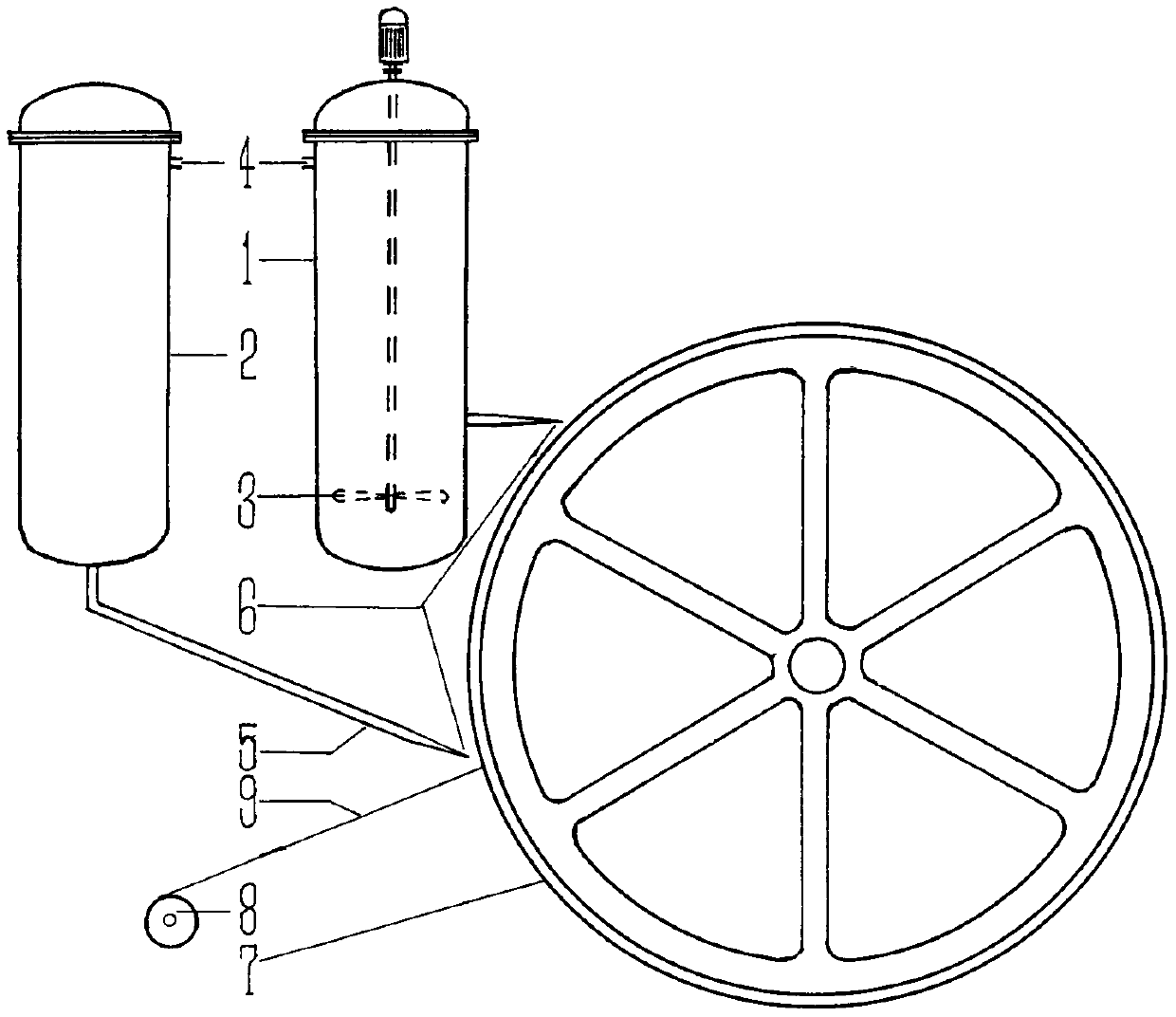

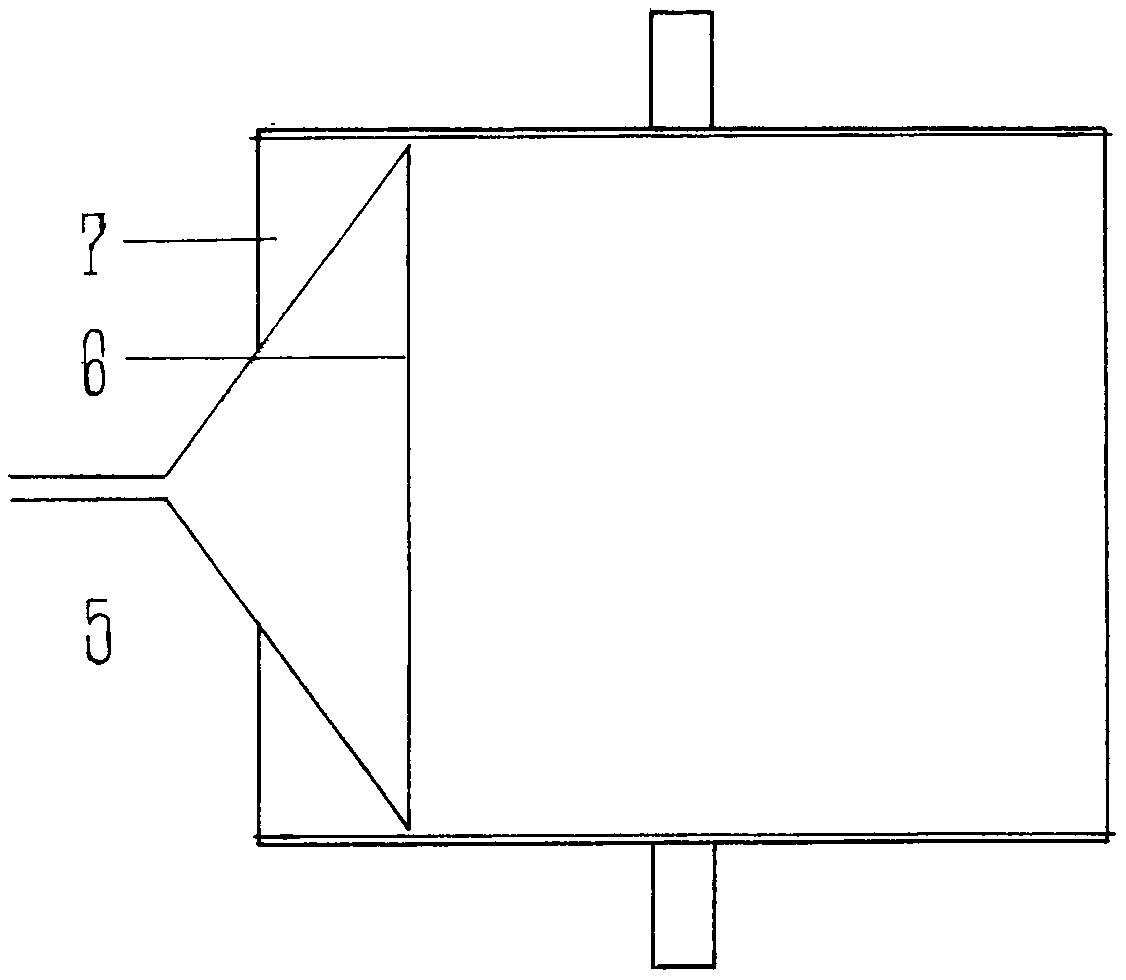

[0025] Such as figure 1 , figure 2 Shown: graphite powder liquid CO of the present invention 2 The method for preparing graphene by continuous spray coating of suspension includes: loading nanoscale graphite powder and liquid CO 2 Seal tank 1 and load liquid CO 2 Seal barrel 2, form the roller 7 of graphene diaphragm 9 and the roll shaft 8 of wrapping graphene diaphragm 9, the agitator 3 that reaches the lower part of seal pot 1 is attached on the seal cover of seal pot 1, and the side wall top one A feed port 4 is arranged on the side, and an output pipe 5 whose end is connected to a linear nozzle 6 is arranged on one side of the middle and lower part of the side wall. A feed inlet 4 is arranged on the upper side of the side wall of the sealed barrel 2, and an output pipe 5 whose end is connected to a linear spout 6 is arranged in the center of the bottom. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com