Patents

Literature

41results about How to "No production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

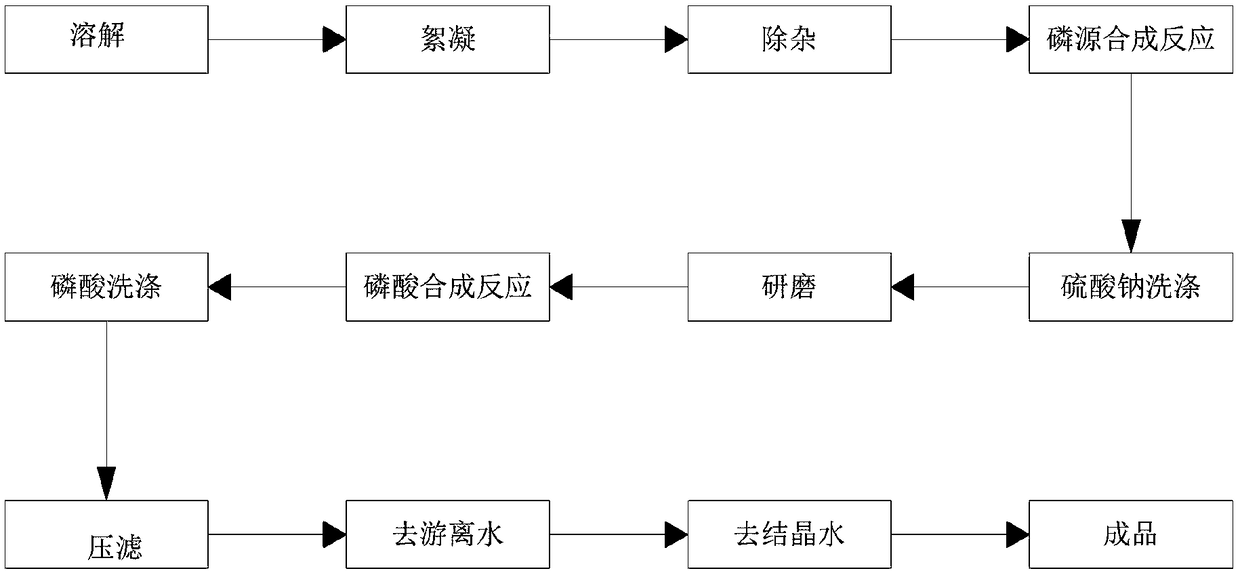

Method for producing battery-grade ferric orthophosphate from titanium dioxide solid waste

The invention belongs to the field of new energy battery materials, and comprises a method for producing battery-grade ferric orthophosphate from titanium dioxide solid waste. The method comprises thefollowing effective steps: adding water for thoroughly dissolving the titanium dioxide solid waste, adding a flocculant, and then performing multi-stage sedimentation filtration to obtain a high-purity ferrous sulfate solution; thoroughly mixing the prepared ferrous sulfate solution and a phosphorus source solution according to a molar ratio of 1:1 in a reaction kettle, then controlling the pH ofthe solution to be 5-7, controlling the temperature at 25-35 DEG C, reacting for about 2 hours while stirring to obtain a ferrous phosphate slurry and sodium sulfate; filtering and washing the ferrous phosphate slurry and the sodium sulfate after a reaction to remove sodium sulfate, slurrying a filter cake after washing, and dispersing and sanding the ferrous phosphate slurry; mixing the sanded ferrous phosphate slurry and phosphoric acid according to a molar ratio of 1:1 to 1:2 in the reaction kettle, adding an oxidizing agent, thoroughly reacting, heating the slurry to 80-100 DEG C, and aging for 2-3 hours; cooling a ferric phosphate slurry after the reaction, washing and performing tympanic membrane suction filtration, then conveying and drying to remove free water, and then removing crystal water through calcination to obtain the battery-grade ferric orthophosphate.

Owner:SHANDONG LUBEI ENTERPRISE GROUP

Tomato gray mold antagonistic strain B-04-glu

The invention provides a tomato gray mold antagonistic strain B-04-glu which is characterized by comprising four steps for the preparation: firstly, a strain of Bacillus cereus for high-efficient antagonistic gray mold is filtered from a soil sample infected by gray mold, and is named as B-04; secondly, bacteria solution which contains the B-04 bacteria is cultured; thirdly, ultrapure water, 1mM Hepes and electric shock buffer solution are used for washing in turn; fourthly, beta-1, 3-dextranase genes are transformed into the B-04 bacteria through electric shock method, and then the antagonistic strain B-04-glu is obtained. The antagonistic strain B-04-glu belongs to biological prevention and cure and does not contain compositions such as pyrilamine, pyrrole, acylamide and so on of chemical pesticide, thereby the antagonistic strain B-04-glu has the advantages of innocuity, no environmental pollution, difficult production of drug resistance, no residue, easy production, long effective period, strong curing ability, good application effect, safety on non-targeted organisms and so on and has wide application prospect.

Owner:SHANDONG UNIV OF TECH

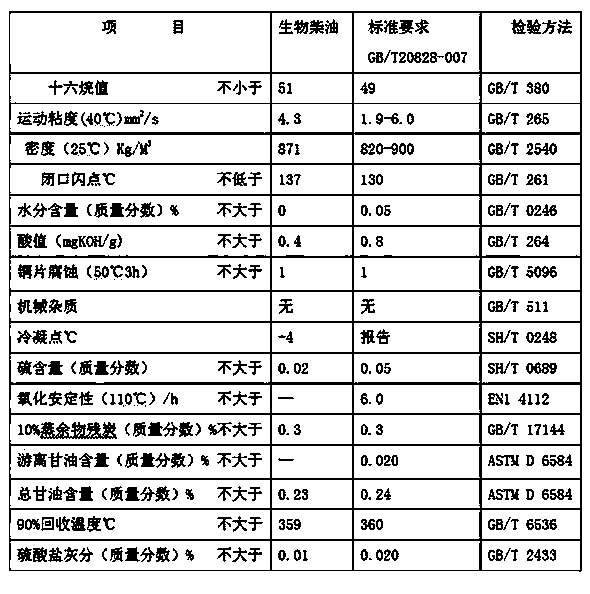

Method for producing biodiesel by means of animal and plant waste oil at high acid value

ActiveCN104004596AEasy to separateLow priceFatty acid esterificationBiofuelsOil and greaseAcetic acid

The invention relates to a preparation method for producing biodiesel by means of animal and plant waste oil at a high acid value, and belongs to the technical field of energy-saving environment-friendly biodiesel manufacturing. The method is characterized in that the collected animal and plant waste oil at the high acid value is processed according to the steps of degumming, pre-esterification, ester exchange, adsorption and decoloring and the like. Ferric sulfate is taken as a pre-esterification catalyst, is low in price and easy to take, does not have high requirements for a reaction kettle and is easy to separate after catalyzation is finished; the catalyst can be reused after being processed, and cost is effectively reduced. During the ester exchange stage, ethyl acetate is added, the reaction speed is increased, complete separation of coarse methyl ester and glycerin is accelerated, washing is not needed in the refining process of the coarse methyl ester, and waste water is prevented from being produced. The yield of products produced in the method is high, and the products meet the requirement of the GB / T2007 standard in China about biodiesel (BD100) for diesel fuel mixing. No waste water is produced in the whole process of production, and the method is environmentally friendly.

Owner:刘火成

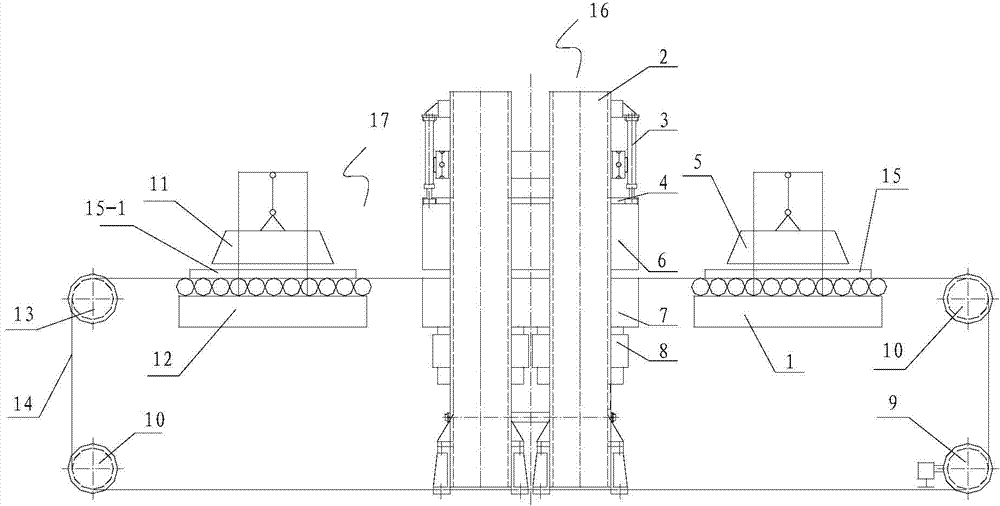

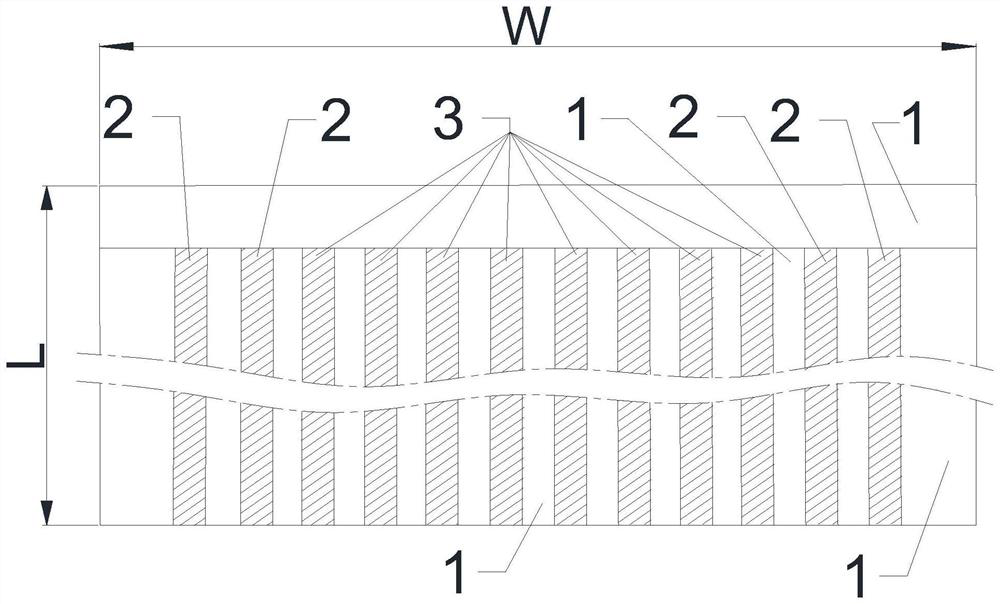

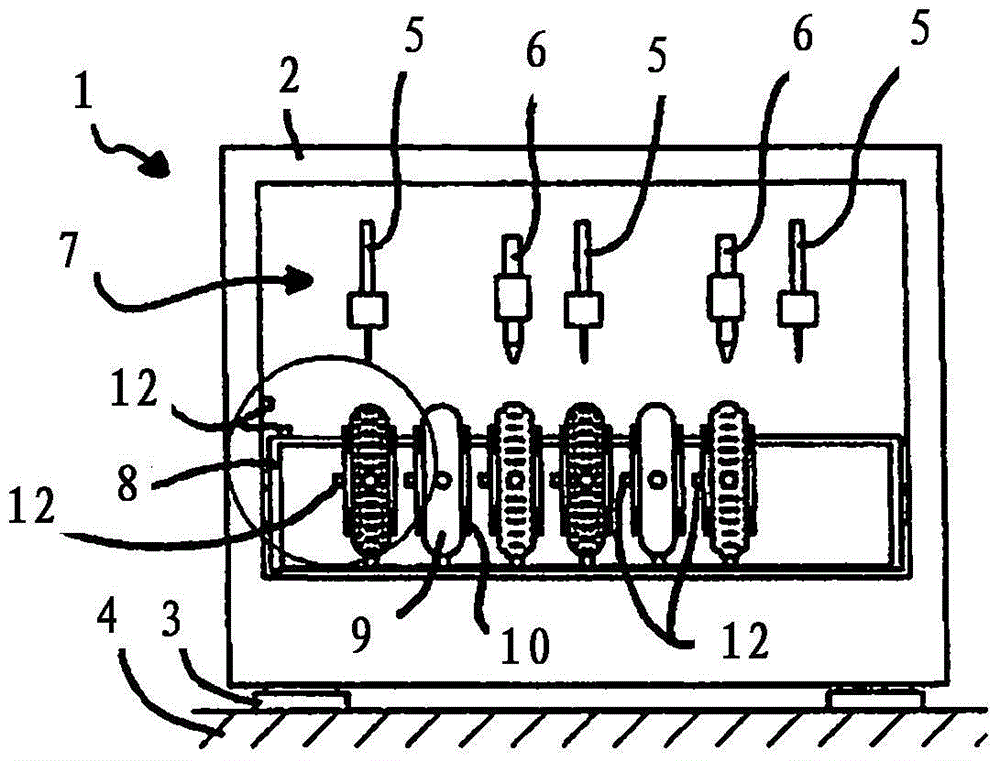

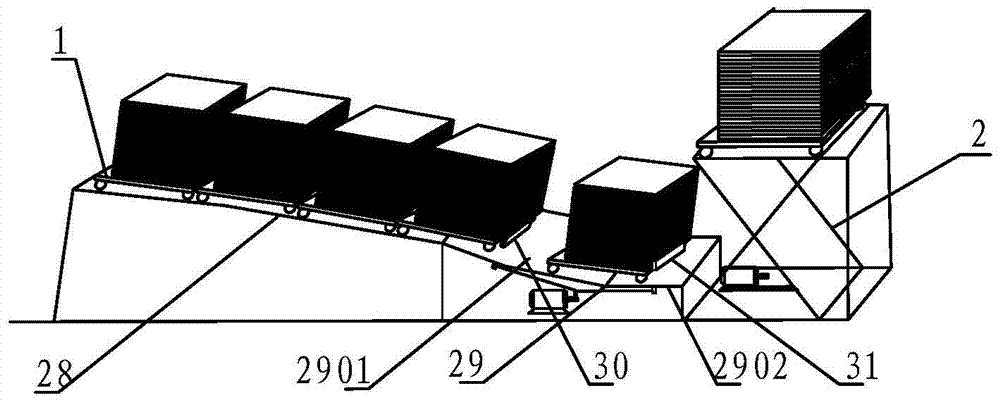

Hydraulic machine for single-piece fiber cement plate pressing

InactiveCN104708842ALow powerReduce deliveryCeramic shaping apparatusPress ramEngineeringHigh pressure water

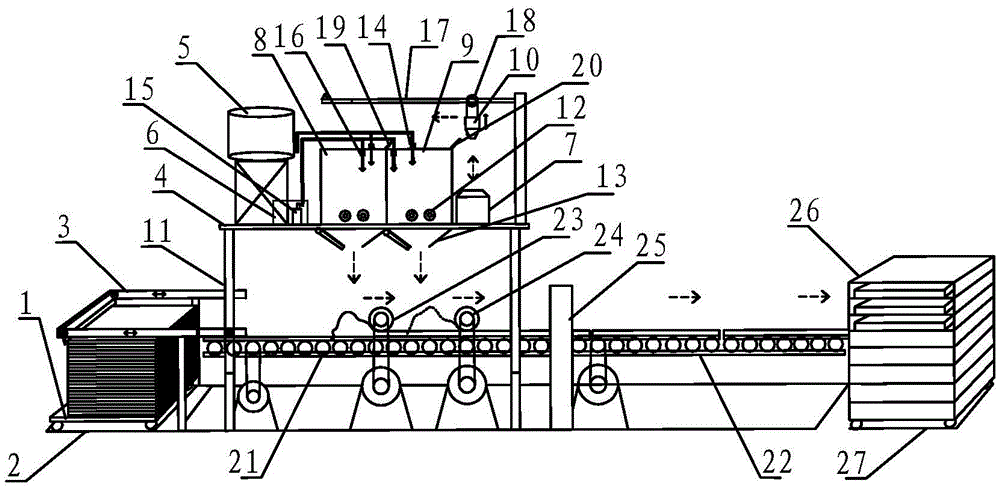

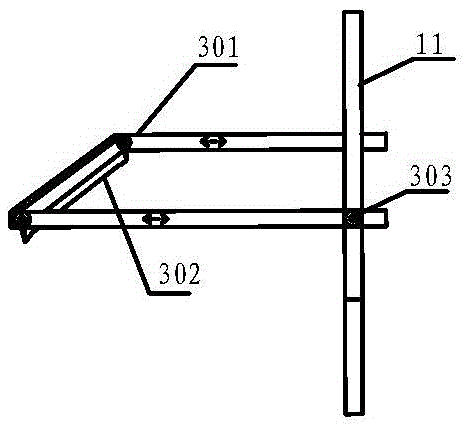

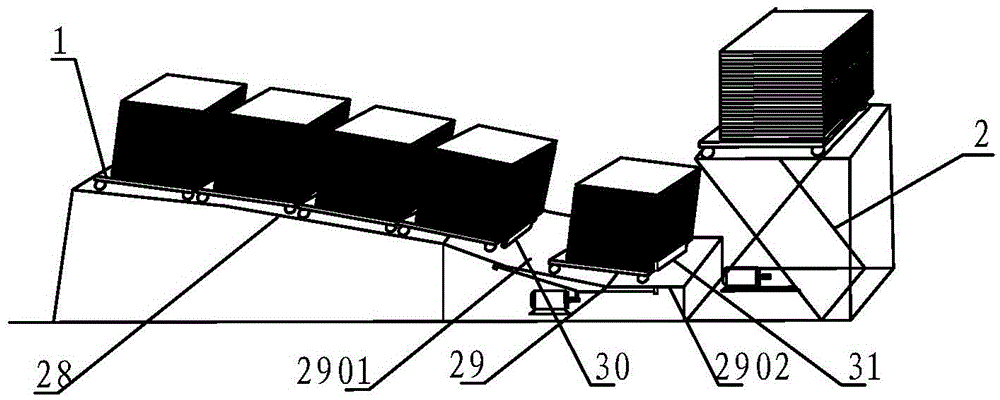

The invention relates to a hydraulic machine for single-piece fiber cement plate pressing. The hydraulic machine is characterized by comprising a hydraulic machine body and a multi-station conveying device, the hydraulic machine body is arranged in the middle of the multi-station conveying device, the multi-station conveying device comprises a conveyer belt, a driving roller, two tensioning rollers and a high-pressure water cleaning roller, the driving roller, one tensioning roller, the high-pressure water cleaning roller and the other tensioning roller are arranged in sequence to form the cyclic multi-station conveying device, a plate blank conveying machine and a dewatered plate blank conveying machine are arranged on the left side and right side of the hydraulic machine body, and plate blank suckers are arranged above the plate blank conveying machine and the dewatered plate blank conveying machine respectively. The hydraulic machine has the advantages that a plate blank or a pressed dewatered plate blank is directly conveyed to the pressing station or stacking station through the multi-station conveying device extending to the two ends of the hydraulic machine body, and vertical drainage can be achieved quickly during pressing due to the fact that the plate blank is conveyed through the fibrage conveyer belt.

Owner:天津太平洋超高压设备有限公司

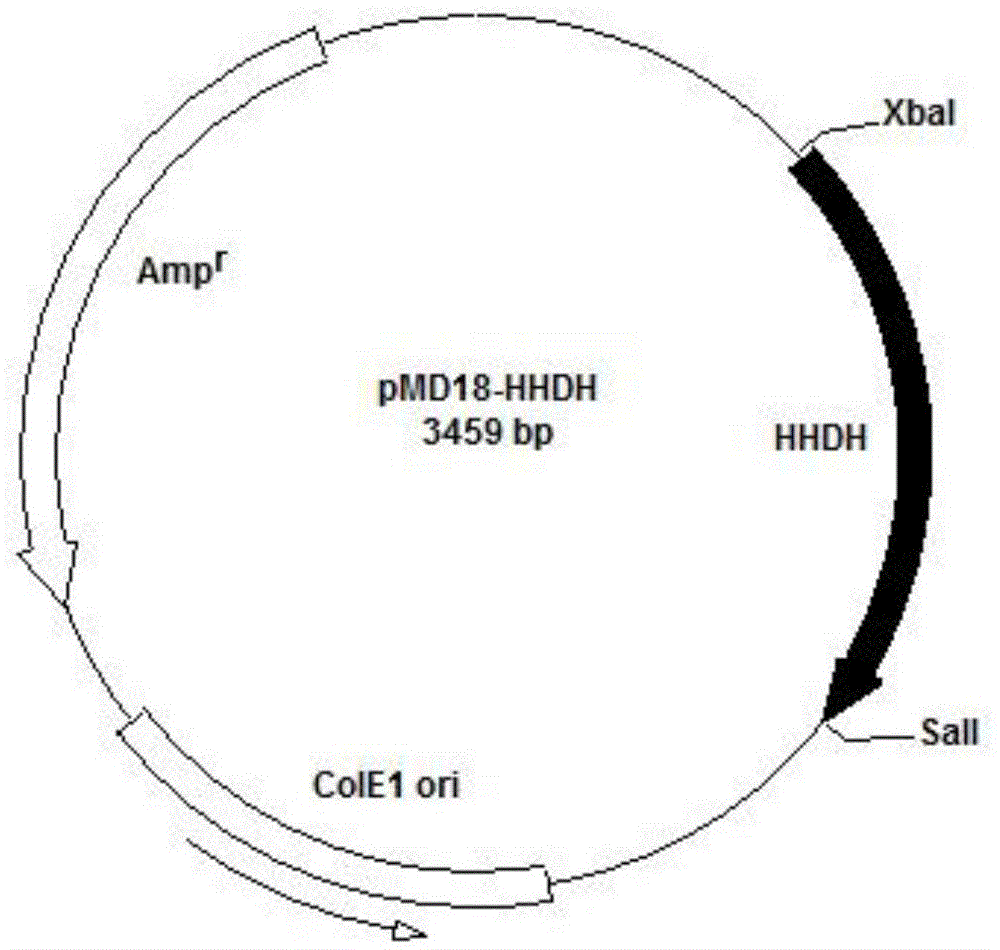

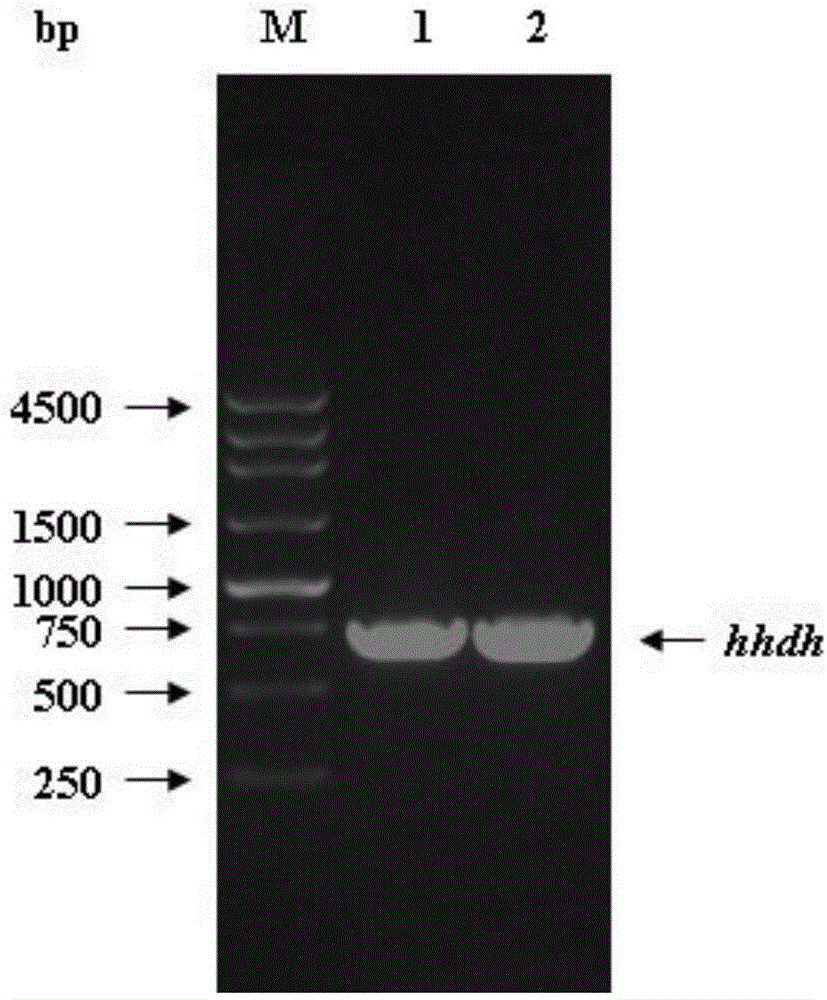

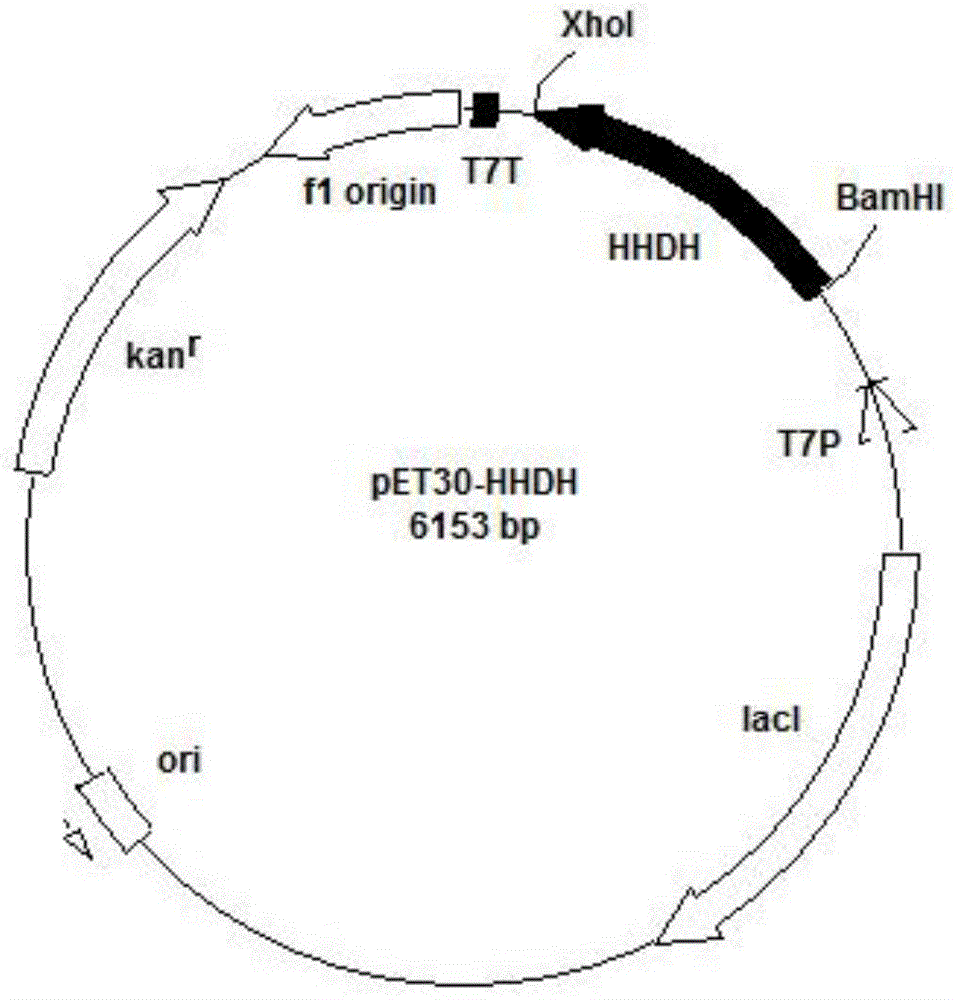

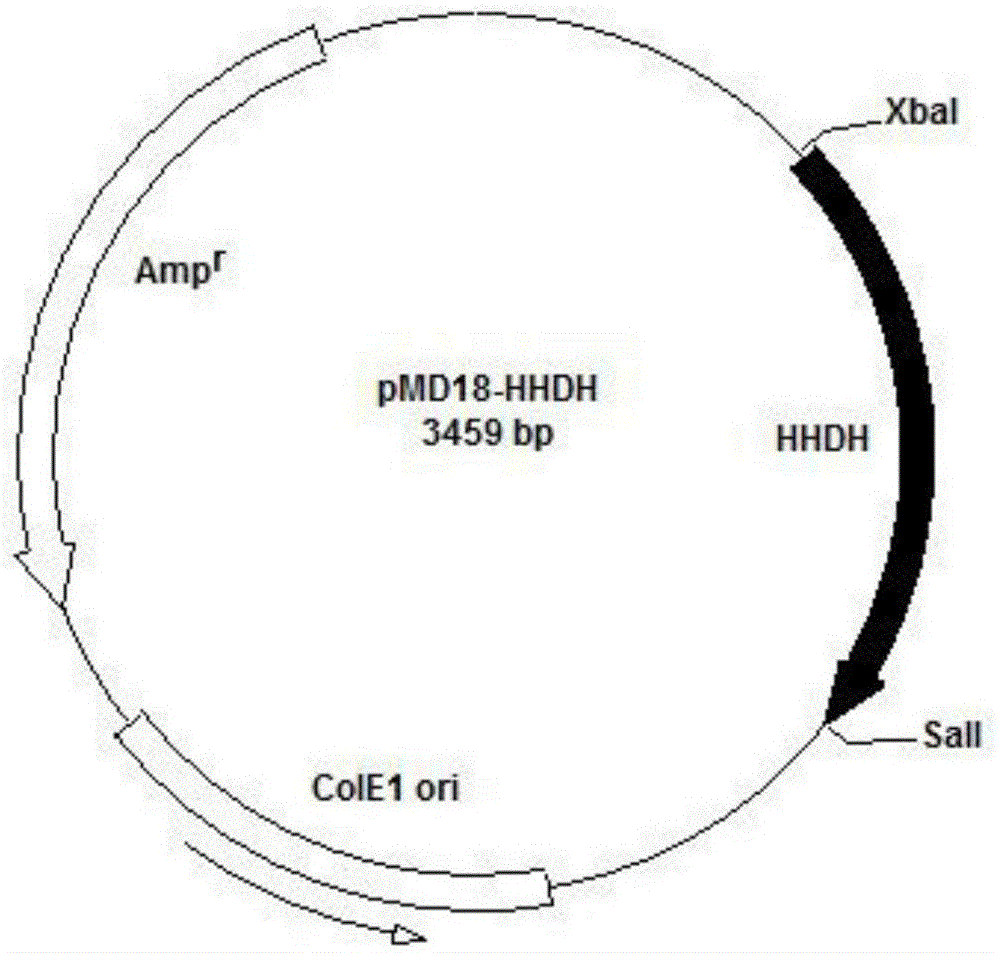

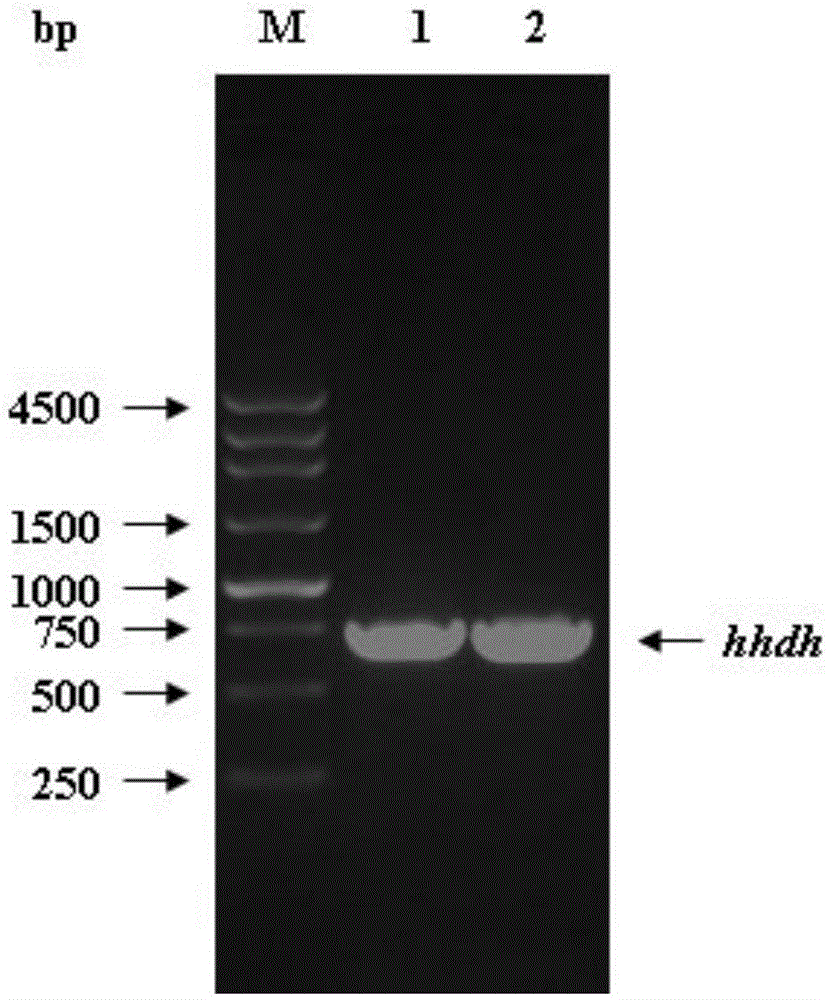

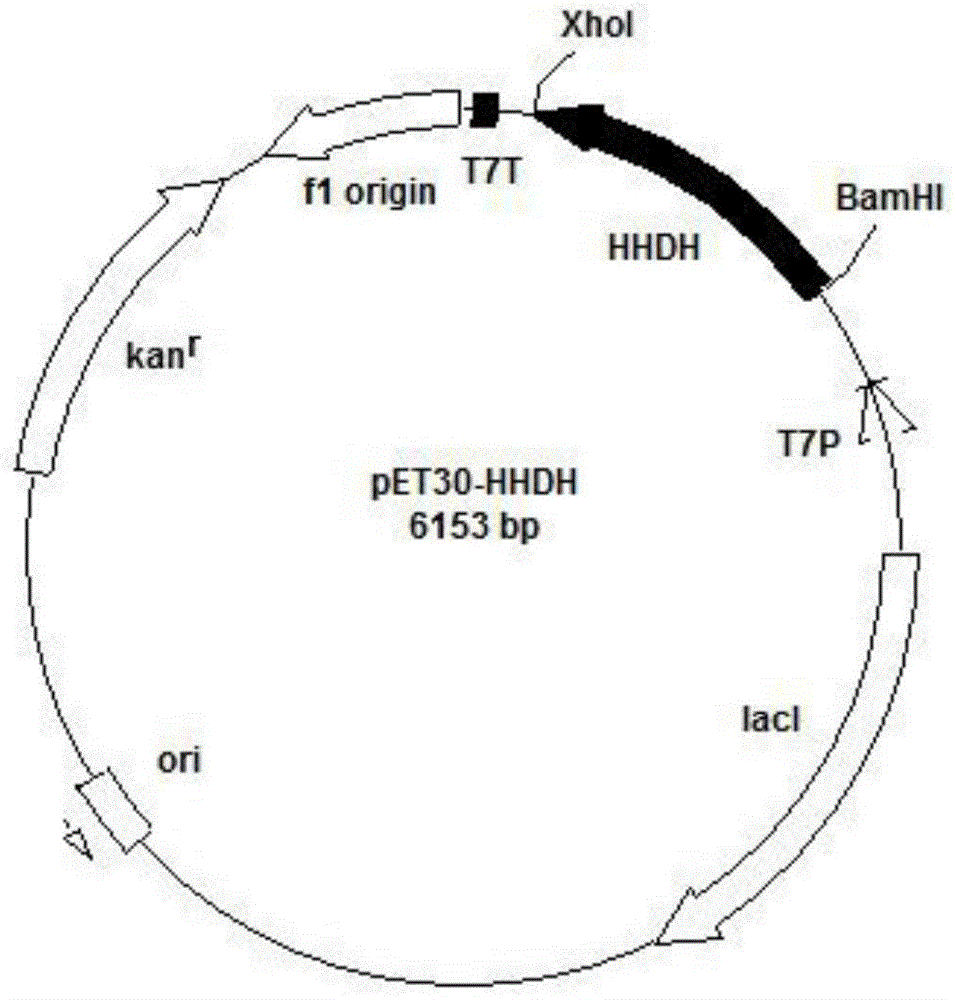

Engineering bacterium and method for preparing tert-butyl (3R, 5R) 6-cyan-3, 5-dyhydroxyl hexanoate

ActiveCN104087547AReduce manufacturing costSimple production processBacteriaMicroorganism based processesEnzymeEthyl Chloride

The invention discloses an engineering bacterium and a method for preparing tert-butyl (3R, 5R) 6-cyan-3, 5-dyhydroxyl hexanoate. The engineering bacterium comprises a host cell and a target gene transformed into the host cell, wherein the target gene is a halohydrin dehalogenase gene. The method comprises the following steps: culturing the engineering bacterium and inducing the halohydrin dehalogenase gene to express; centrifuging to take the cell; resuspending by a buffer liquid to obtain a resting cell suspension; adding tert-butyl (3R, 5S) 6-chloro-3, 5-dyhydroxyl hexanoate and NaCN to the resting cell suspension for reacting, and after reaction, separating and purifying a reaction liquid to obtain a product. Through the catalytic effect of the enzyme, the method disclosed by the invention simplifies the production process of tert-butyl (3R, 5R) 6-cyan-3, 5-dyhydroxyl hexanoate, is free from a lot of reaction byproducts and lowers the production cost.

Owner:ZHEJIANG UNIV

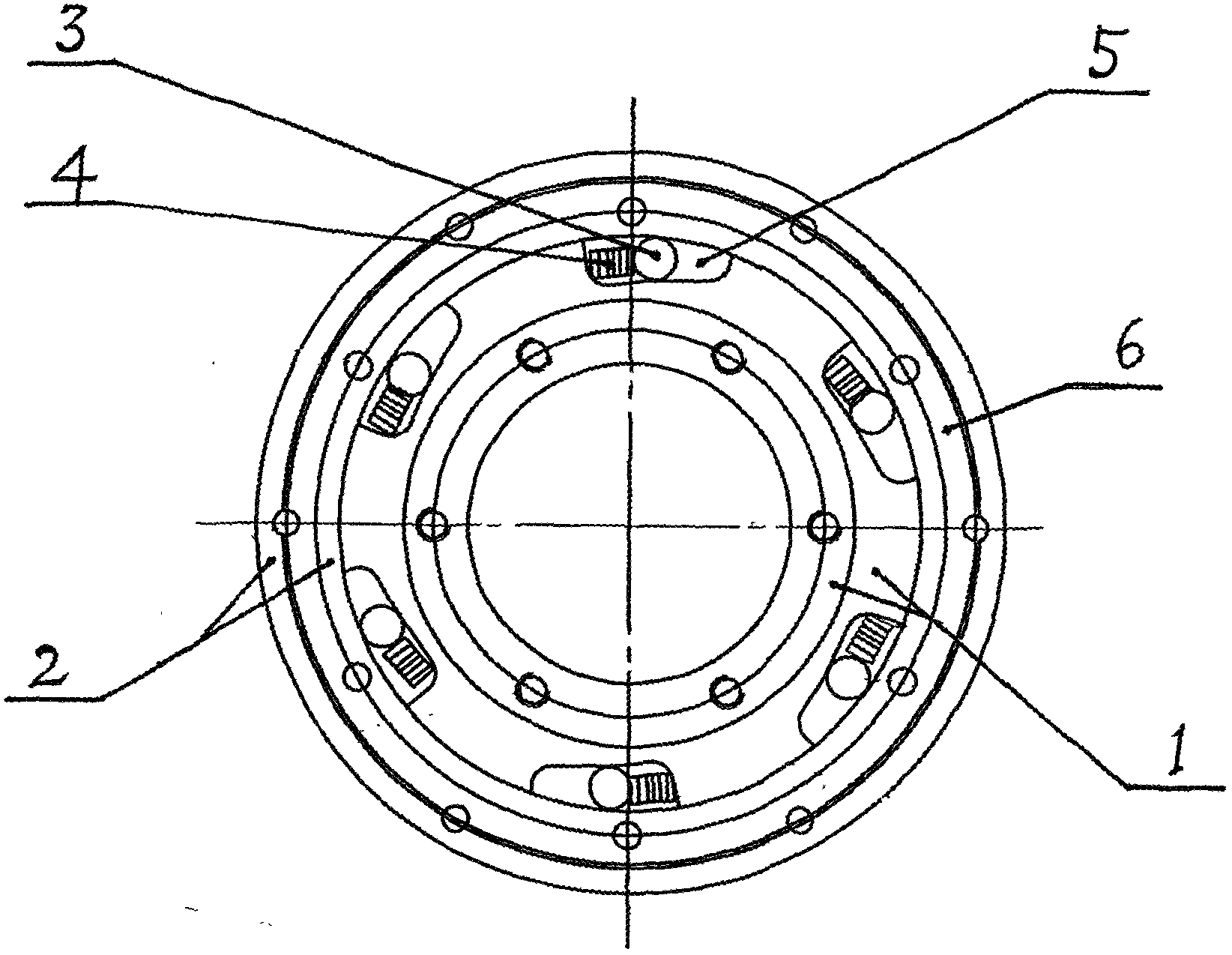

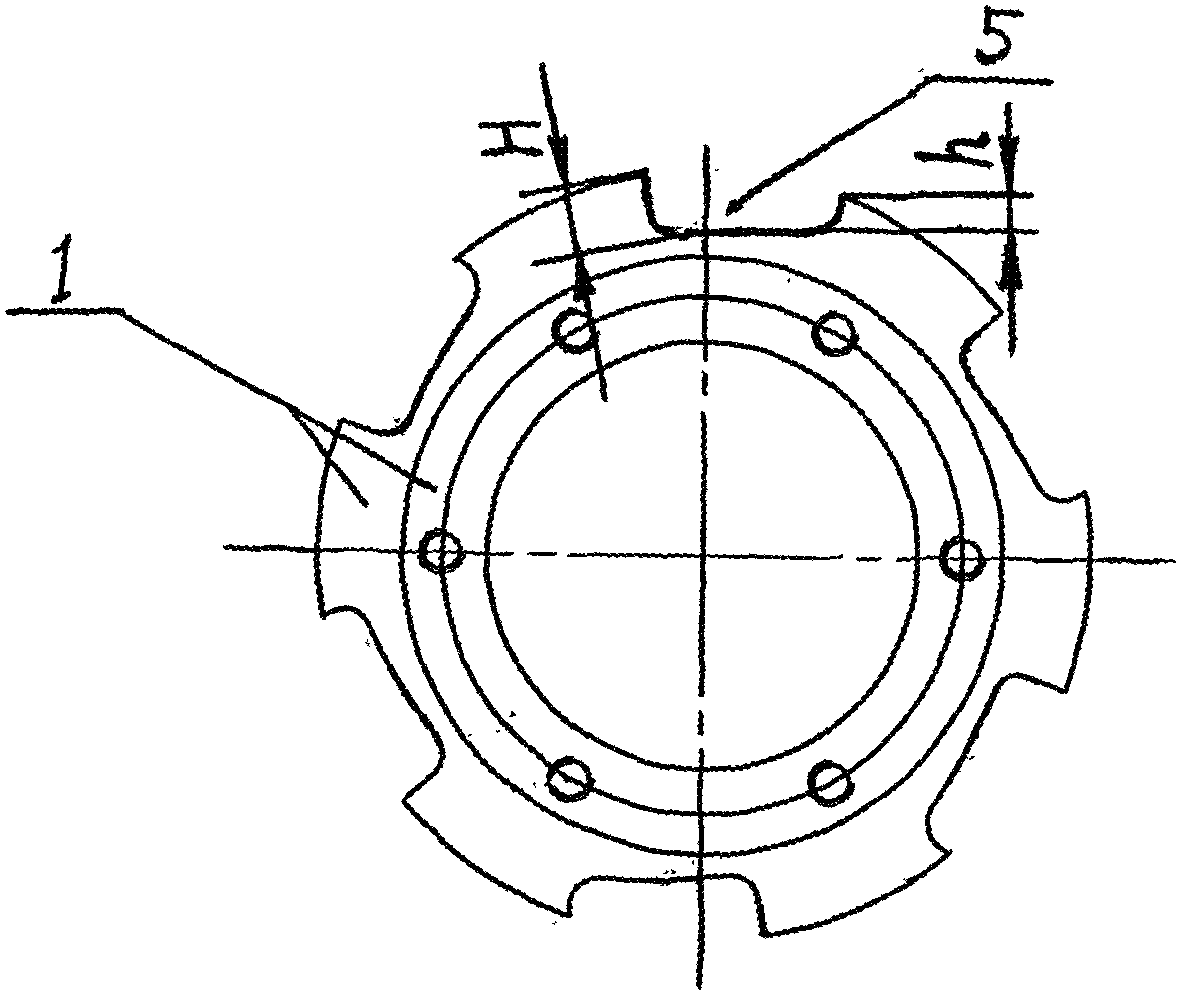

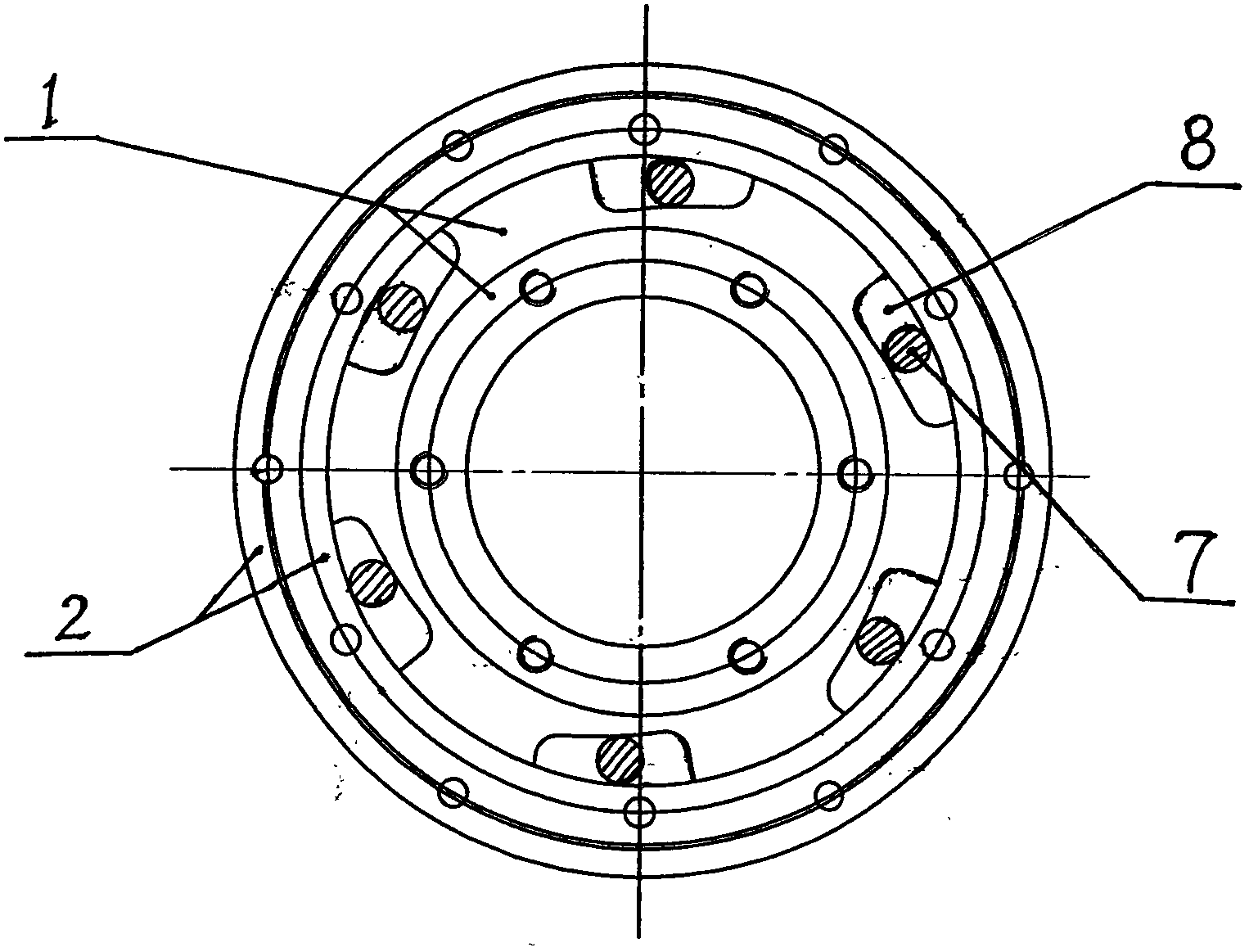

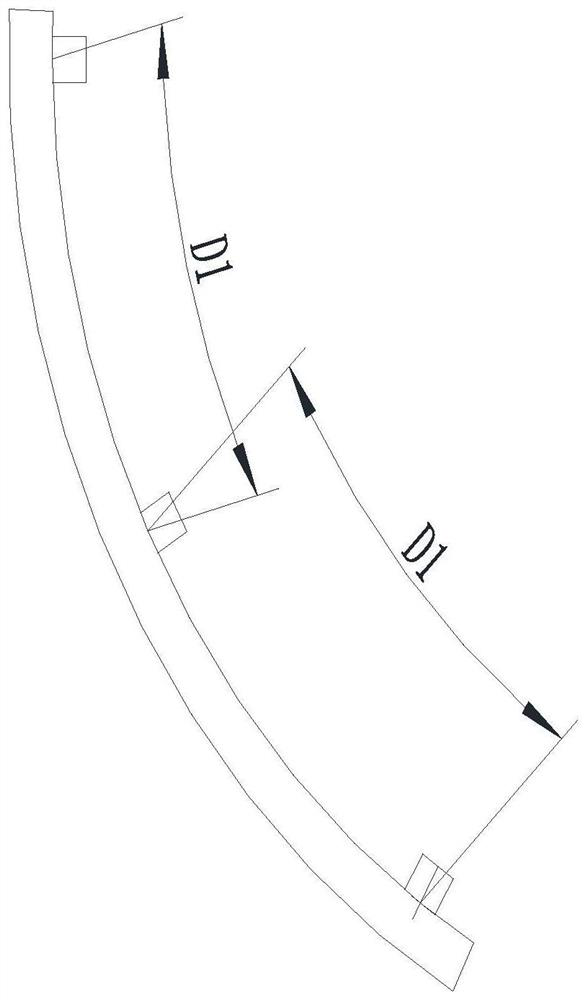

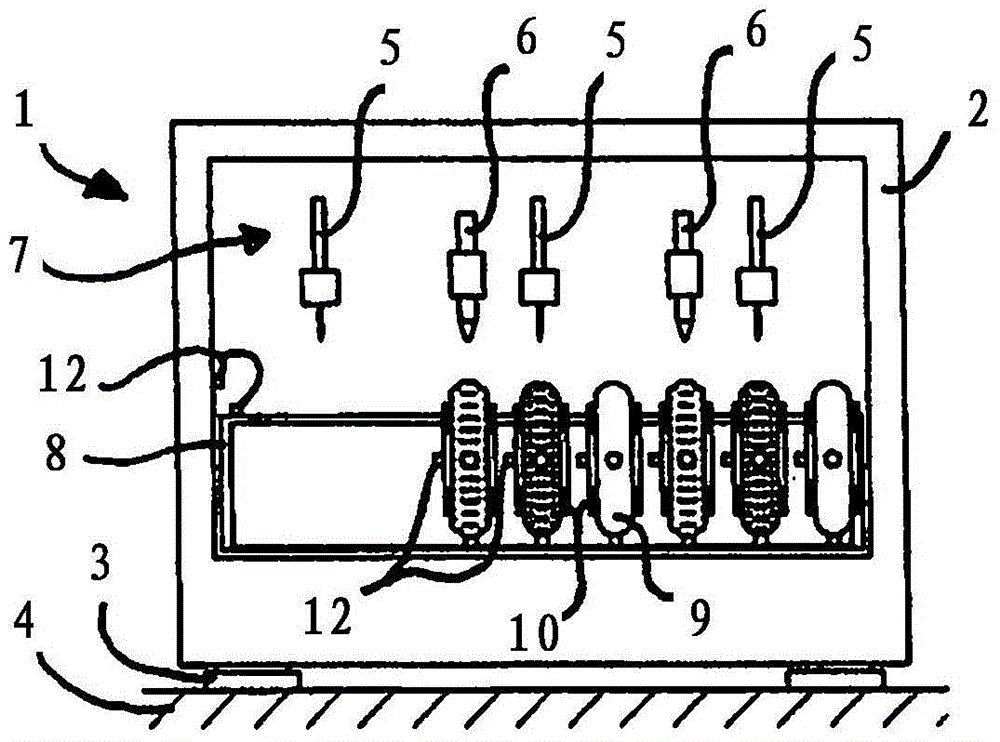

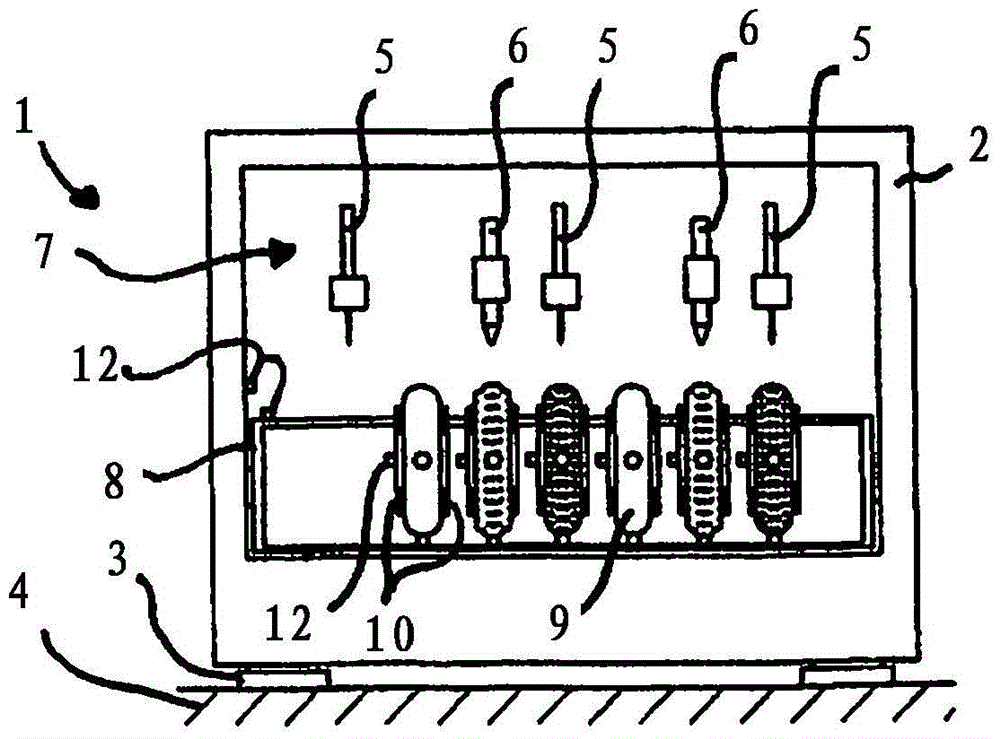

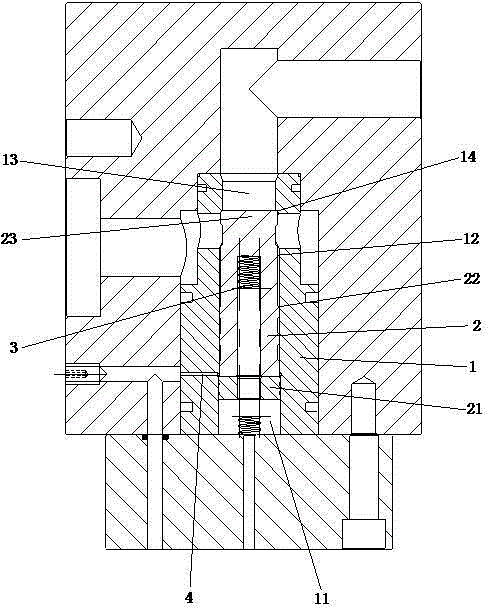

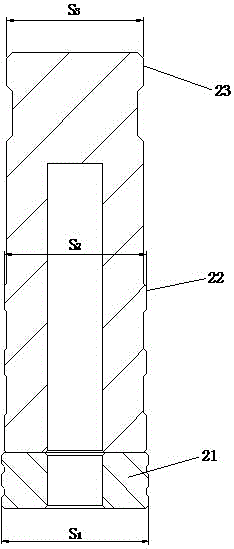

High-reliability clutch mechanism

The invention relates to a high-reliability clutch mechanism which comprises an inner shaft sleeve 1, an outer sleeve ring 2 and a driving component, wherein the outer edge of the inner shaft sleeve 1 is at least provided with a wedge-shaped groove; the driving component is arranged in the wedge-shaped groove, and the driving part, the outer sleeve ring 2 and the wedge-shaped groove form a one-way close fit structure capable of realizing forward-rotation clamping. The high-reliability clutch mechanism can be used for solving the problems of high fault occurrence possibility, poor reliability and high abrasion possibility of an existing clutch mechanism, has the advantages of high operation reliability, high stability, low noise, simple structure, easiness for manufacturing, high durability and the like, and is mainly used for manufacturing clutch devices of various vehicles and power devices.

Owner:马骥 +1

Method for Preparing Ferrite Catalyst

InactiveUS20160184806A1Increase conversion rateHigh selectivityMolecular sieve catalystHeterogenous catalyst chemical elementsDehydrogenationMixed metal

Disclosed are a ferrite catalyst, its preparation method and use. The catalyst has a formula of FeAaDbOc, wherein A is Mg atom, Zn atom or a mixture of these two atoms in any ratio; D is one or more atoms elected from the group consisting of Ni, Co, Mn, Ca, Mo or V; a=0.01˜0.6; b=0˜0.30; c is a number satisfying the valence. The catalyst is prepared by a method comprising mixing the metal oxide precursors according to the chemical ratios and grinding by ball milling to obtain the ferrite catalyst. The catalyst exhibits excellent activity and selectivity when used in a reaction for preparing butadiene by oxidative dehydrogenation of butene. The preparation of the catalyst is simple, controllable and well repeatable, with reduced waste water and waste gas during preparation.

Owner:SHANGHAI HUAYI ACRYLIC-ACID CO LTD +1

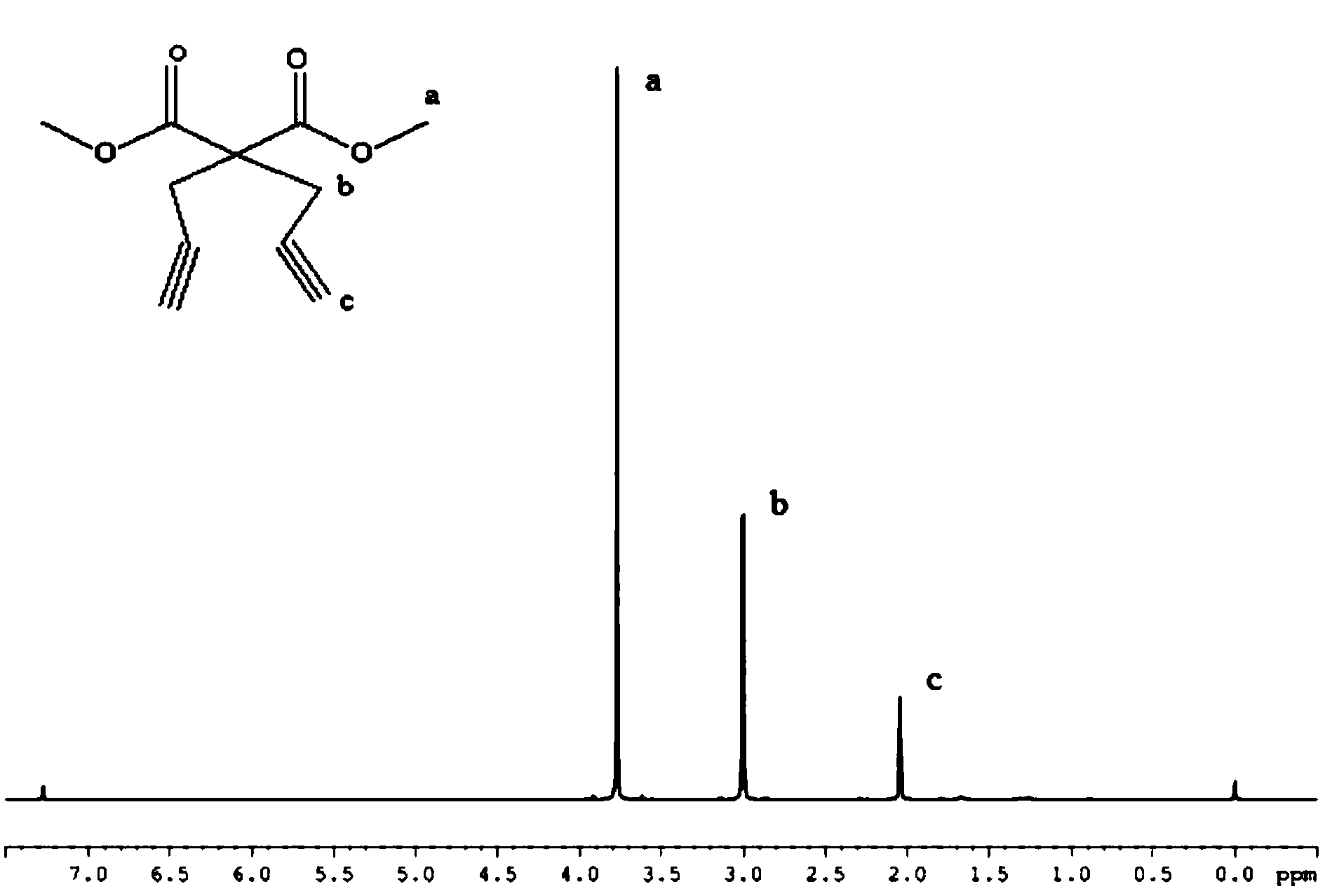

Preparation method for GAP base elastomer with non-isocyanate curing manner

ActiveCN103435800AThe reaction steps are simpleReduce distractionsOrganic compound preparationCarboxylic acid esters preparationMethyl malonateIsocyanate

The invention relates to a preparation method for a GAP base elastomer with a non-isocyanate curing manner. The preparation method comprises: 1) preparing 2,2-propargyl dimethyl malonate; 2) stirring under a N2 protection condition, adding a glycidyl azide polymer solution to the 2,2-propargyl dimethyl malonate solution to obtain a mixing solution H, adding cuprous chloride to the mixing solution H under N2 protection and stirring, maintaining a temperature of 0-25 DEG C, and carrying out a reaction under a light avoiding condition for 8-24 h to obtain a reaction solution J; and 3) carrying out suction filtration and rotary evaporation on the reaction solution J, and evaporating the solvent to obtain the GAP base elastomer with the non-isocyanate curing manner. According to the present invention, the preparation process is simple, the obtained product has good mechanical property, and the GAP content in the elastomer is high, such that the elastomer has high energy and has great potential application values in the development fields of high energy cleaning propellants based on azide, PBX explosives and the like.

Owner:WUHAN UNIV OF TECH

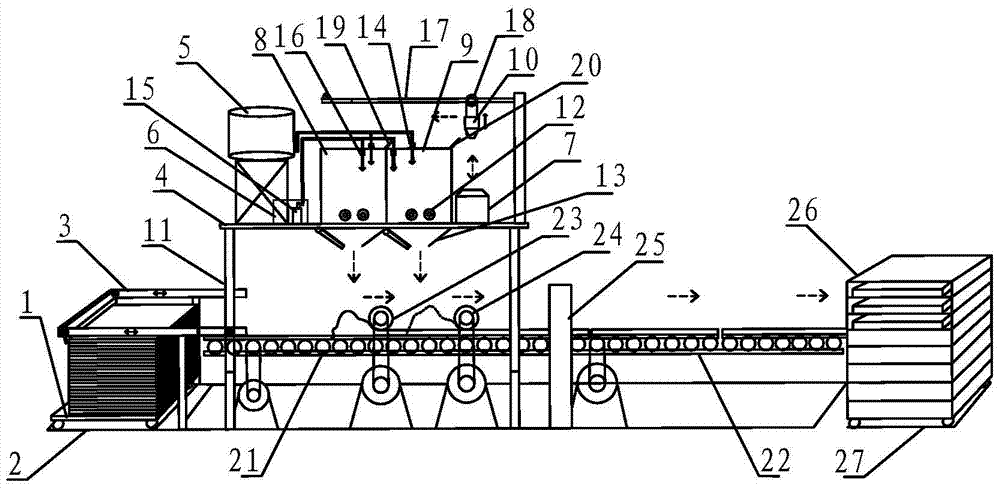

Adhesive polystyrene granule heat preservation plate automatic production apparatus and method

InactiveCN105573280AImprove cutting accuracyImprove yieldTotal factory controlProgramme total factory controlProduction lineMaterials preparation

The invention discloses an adhesive polystyrene granule heat preservation plate automatic production apparatus and method. The apparatus comprises a control device as well as a liner plate laying device, a material preparation device, a plate conveying belt, a leveling device, a cutting device and a finished product plate storage device; the liner plate laying device is arranged at the inlet of the plate conveying belt; the material preparation device is arranged above the front end of the plate conveying belt; the material paving device is arranged above the plate conveying belt and is located behind the material preparation device; the cutting device is arranged above the rear end of the plate conveying belt; and the finished product plate storage device is arranged at the exit of the plate conveying belt. According to the apparatus and method of the invention, the control device controls various kinds of devices, so that each link can perform automatic production according to technical control so as to work stably and orderly, so that a set of full-automatic adhesive polystyrene granule heat preservation plate production line can be formed; the production efficiency of adhesive polystyrene granule heat preservation plates can be improved; plate cutting precision is high; the rate of finished products of the plates is high; and production scraps will not be generated.

Owner:山东美鹰食品设备有限公司

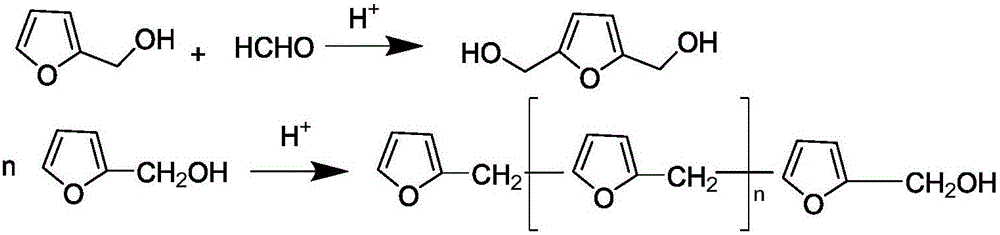

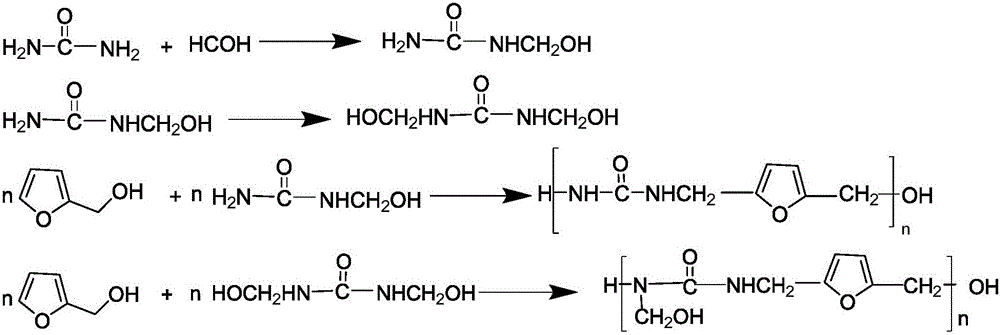

Non-dewatering production method of quick-hardening furan resin

The invention discloses a non-dewatering production method of a quick-hardening furan resin. The method comprises the following steps: adding 50-100 parts by weight of formaldehyde, 75-150 parts by weight of polyformaldehyde and 150-300 parts by weight of furfuryl alcohol into a reaction kettle, stirring uniformly, adding 0.01-0.05 part by weight of organic acid catalyst, heating, and keeping the temperature to react; continuing adding 50-100 parts by weight of urea into a reaction kettle, heating, and keeping the temperature to react; and continuing adding 400-800 parts by weight of furfuryl alcohol, cooling to room temperature by stirring, and discharging. Polyformaldehyde is used instead of part of formaldehyde to react with furfuryl alcohol, thereby lowering the water content in the reaction environment, enhancing the reaction speed, eliminating the dewatering process, lowering the energy consumption and material loss, and achieving the effect of wastewater-free production. When the non-dewatering production method provided by the invention is in actual use, the ratio of the stripping time to the usable time can reach 9:1, thereby greatly enhancing the production efficiency.

Owner:共享新材料(山东)有限公司

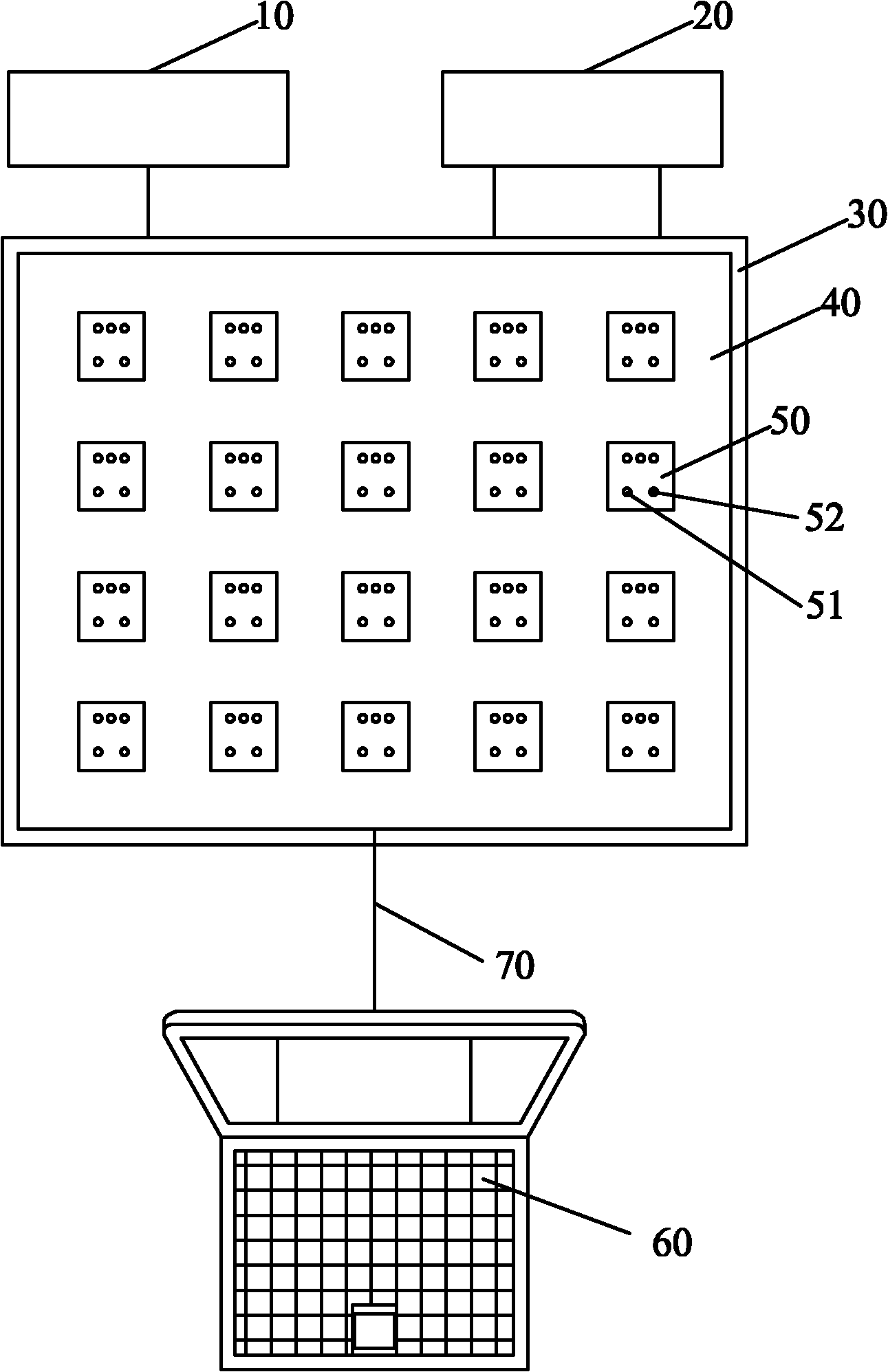

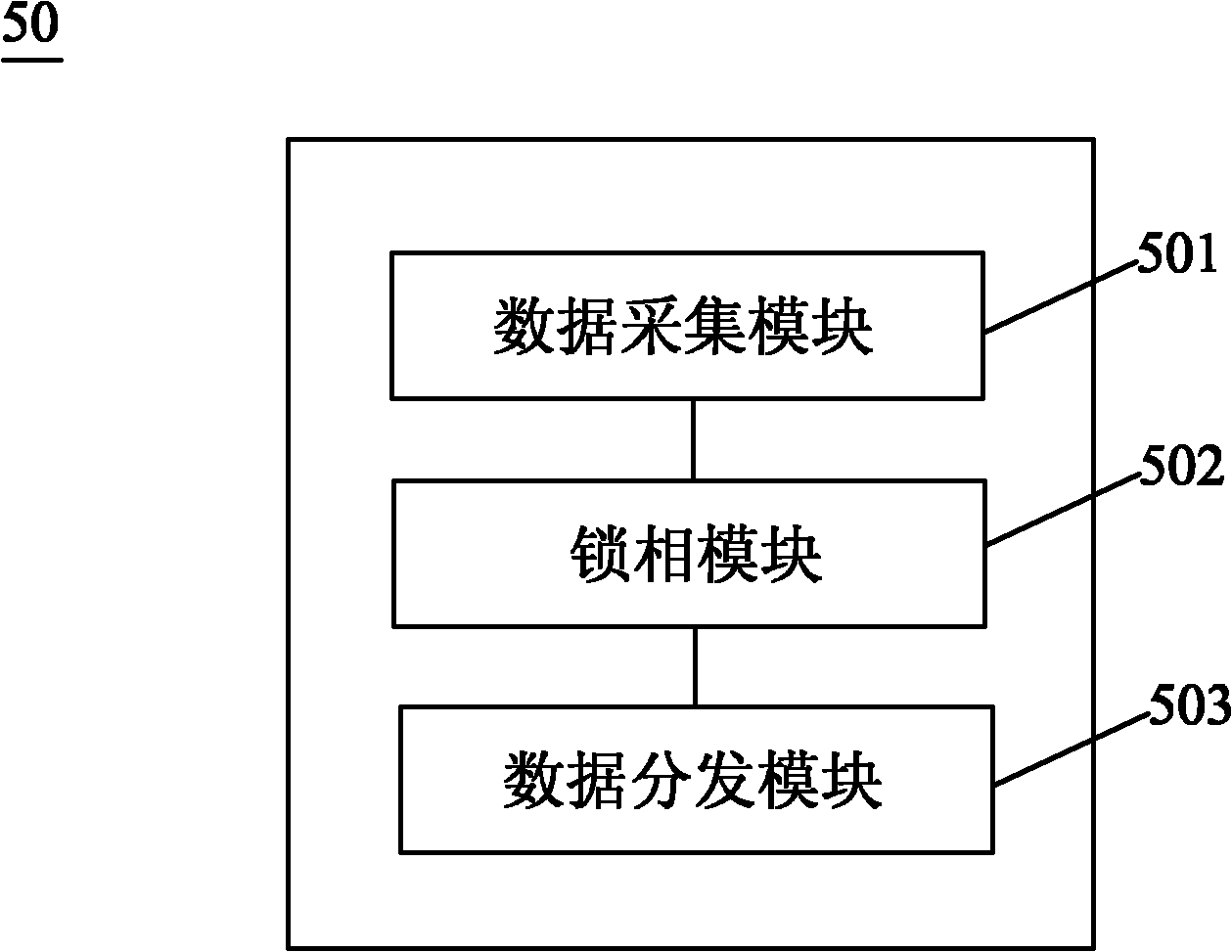

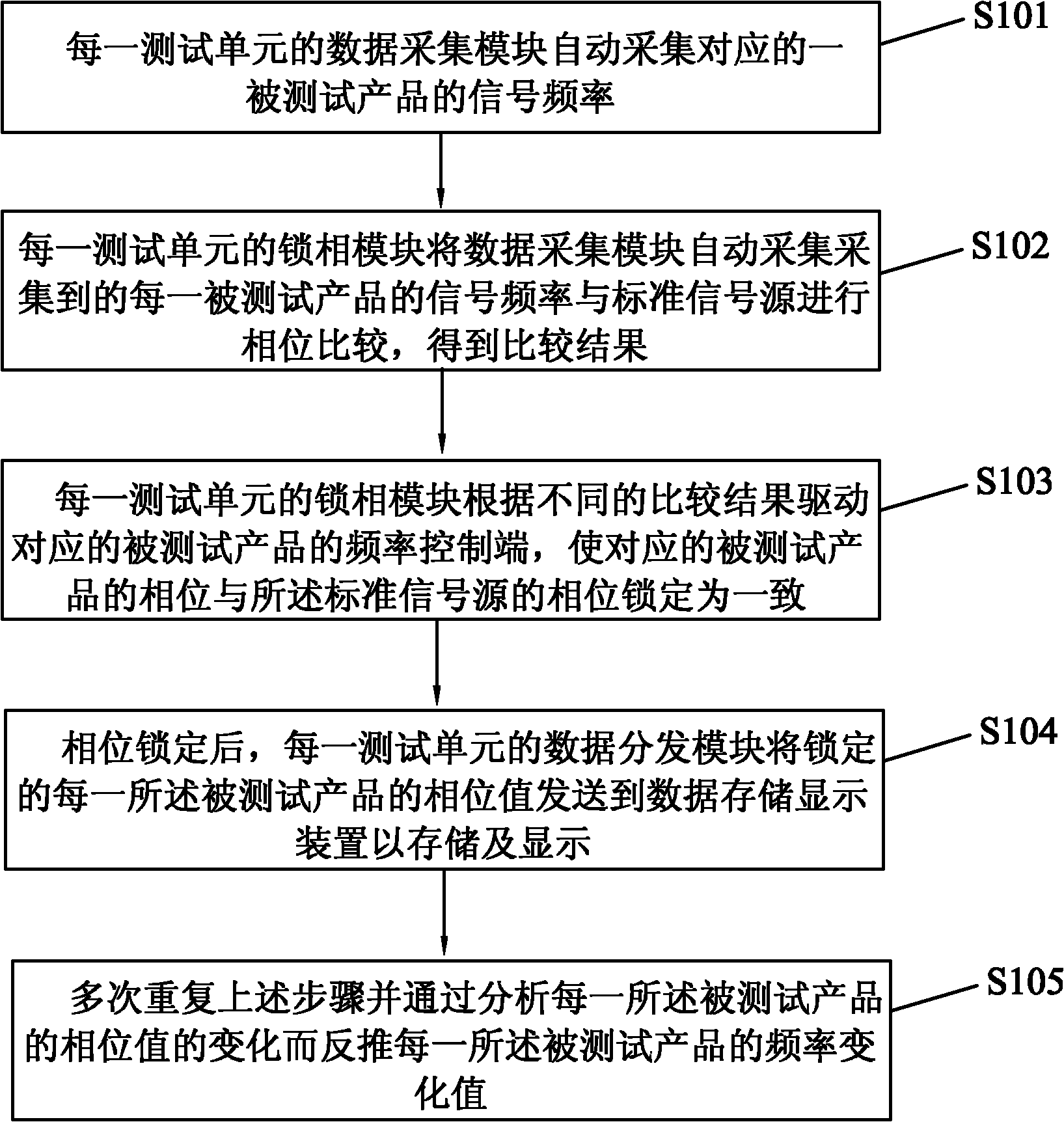

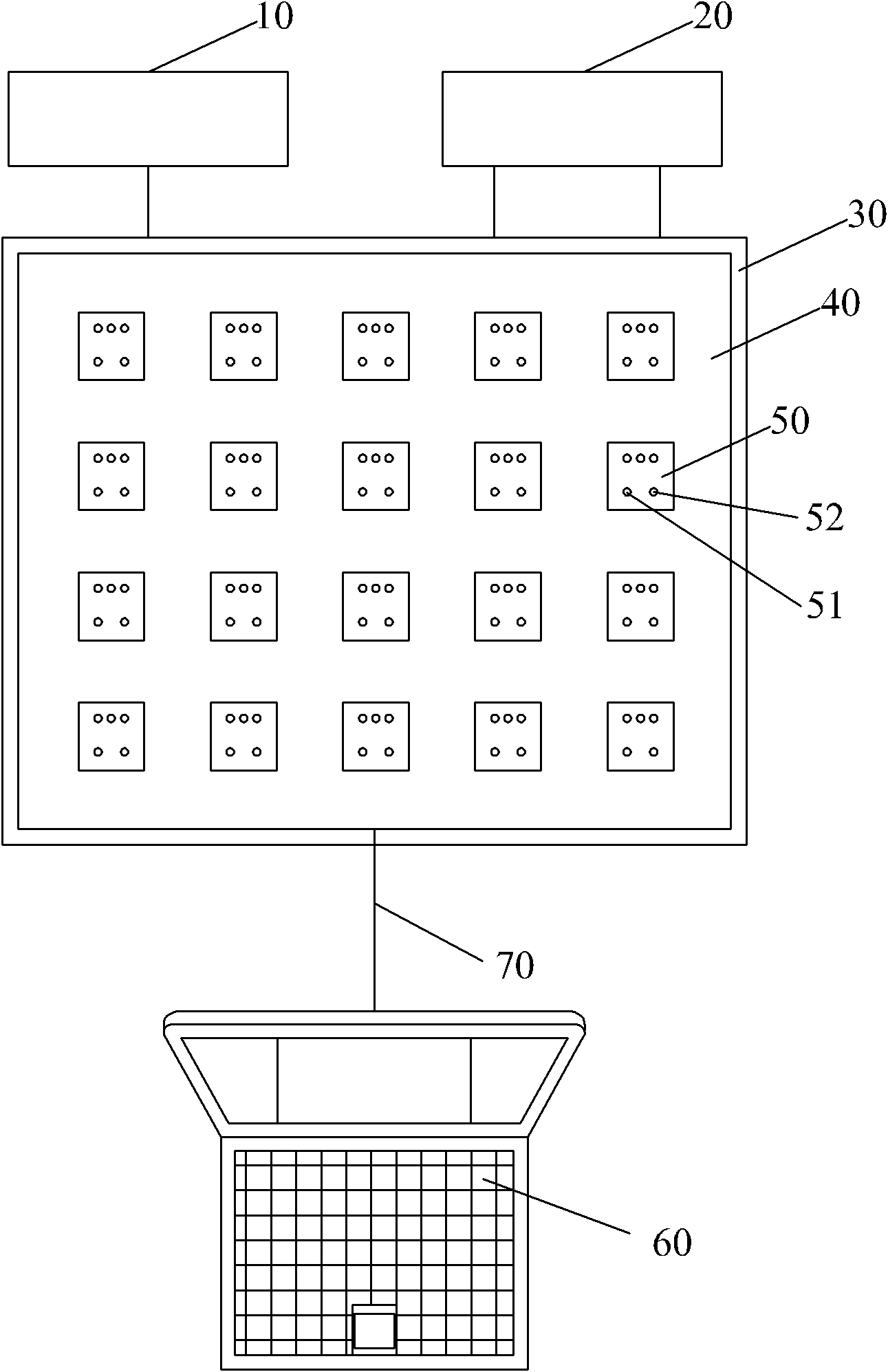

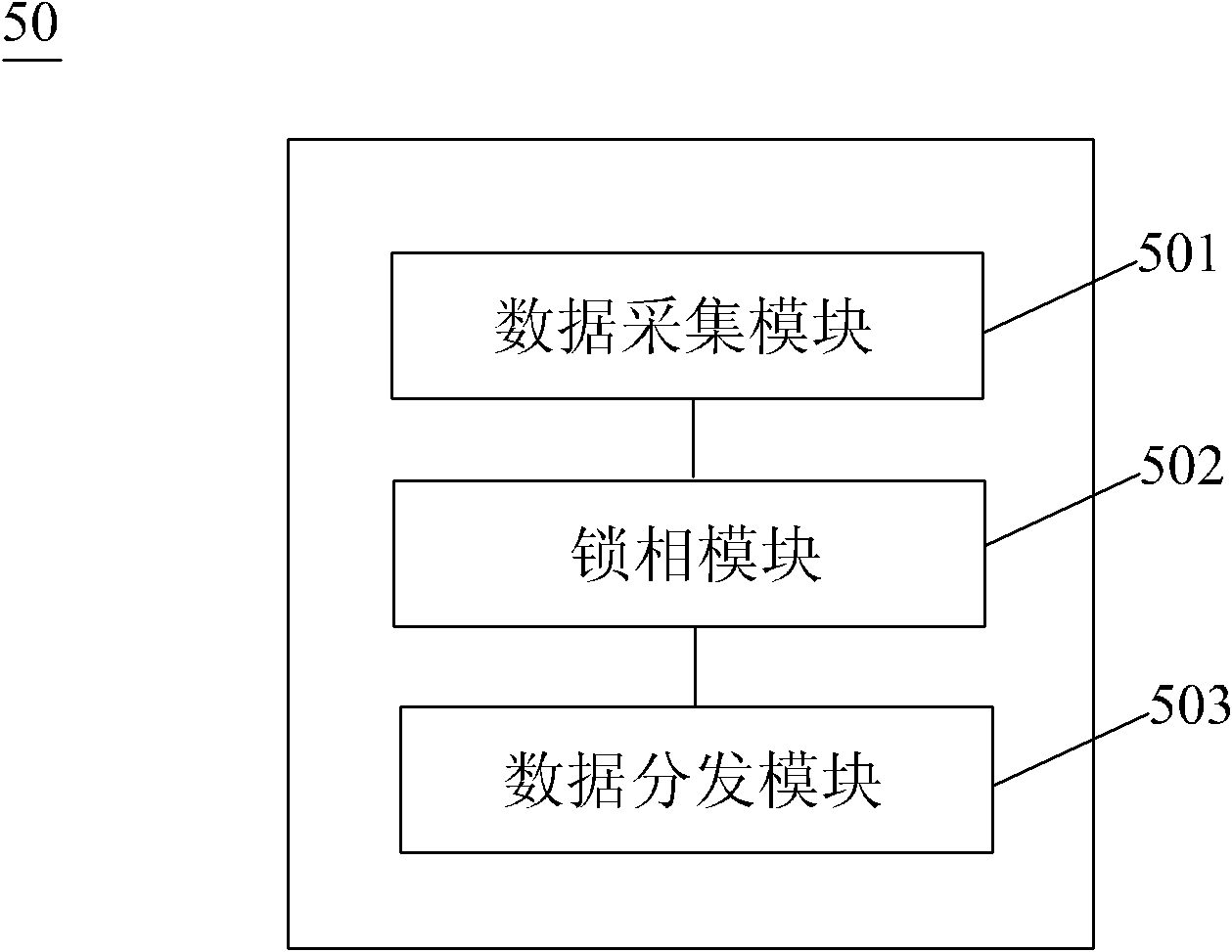

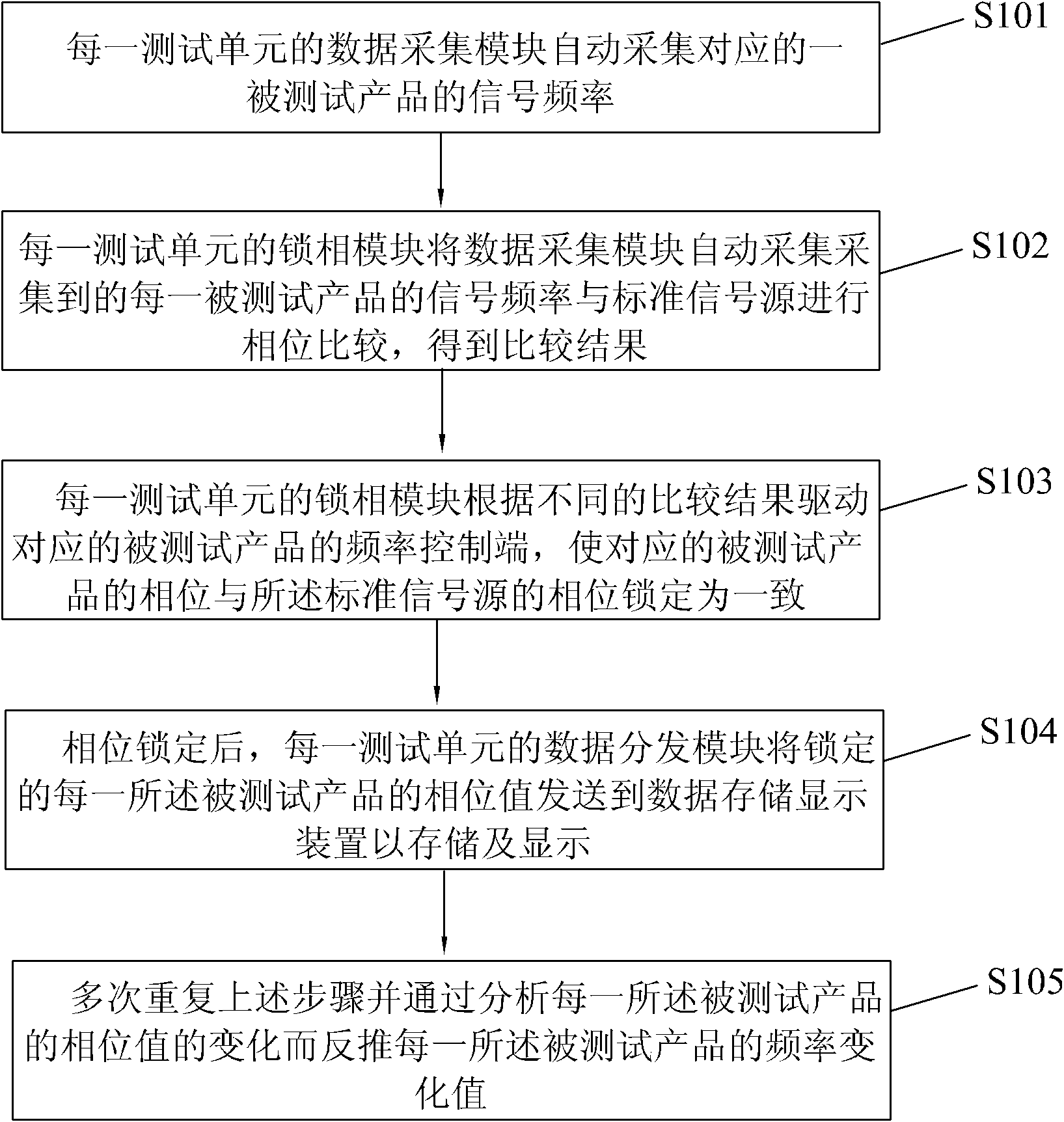

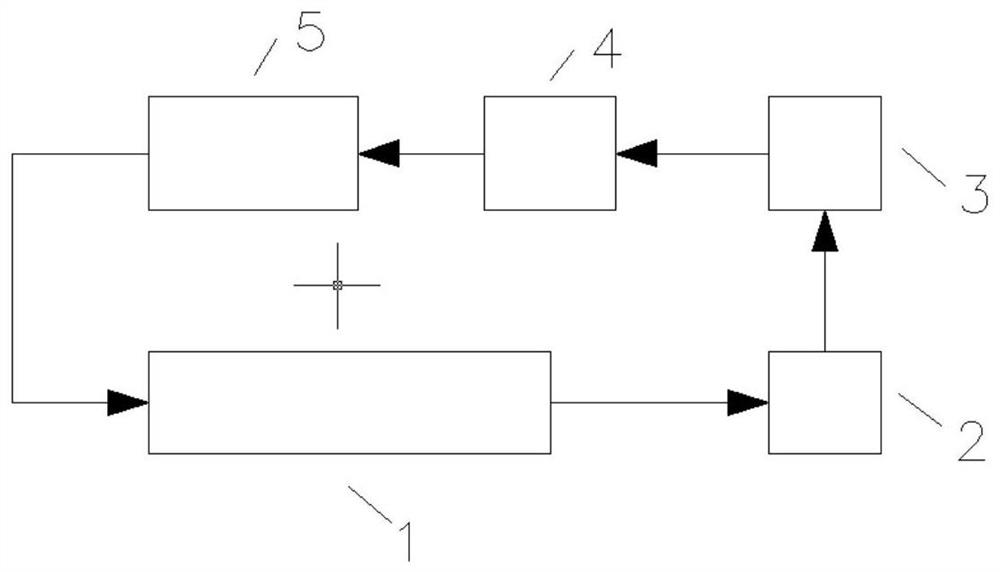

High-frequency and high-speed frequency testing system and method based on phase locking technique

ActiveCN102109552AImprove isolationImprove anti-interference abilityFrequency to phase shift conversionDisplay deviceData acquisition

The invention discloses a high-frequency and high-speed frequency testing system based on a phase locking technique, comprising a standard signal source, a power supply device, a PCB (printed circuit board), a plurality of testing units arranged on the PCB and a data storage and display device, wherein the standard signal source is electrically connected with each testing unit respectively; each testing unit comprises a data acquisition module, a phase locking module and a data distribution module; the data acquisition module is used for acquiring the signal frequency of a tested product correspondingly; the phase locking module is used for carrying out phase comparison on the acquired signal frequency of the tested product and the standard signal source so as to obtain a comparison result, driving the corresponding tested product according to the comparison result and leading the phase of the tested product to be consistently locked with the phase of the standard signal source; and the data distribution module is used for outputting a phase value of the locked tested product to the data storage and display device for storage and display. The invention also discloses a high-frequency and high-speed frequency testing method based on the phase locking technique.

Owner:GUANGDONG DAPU TELECOM TECH CO LTD

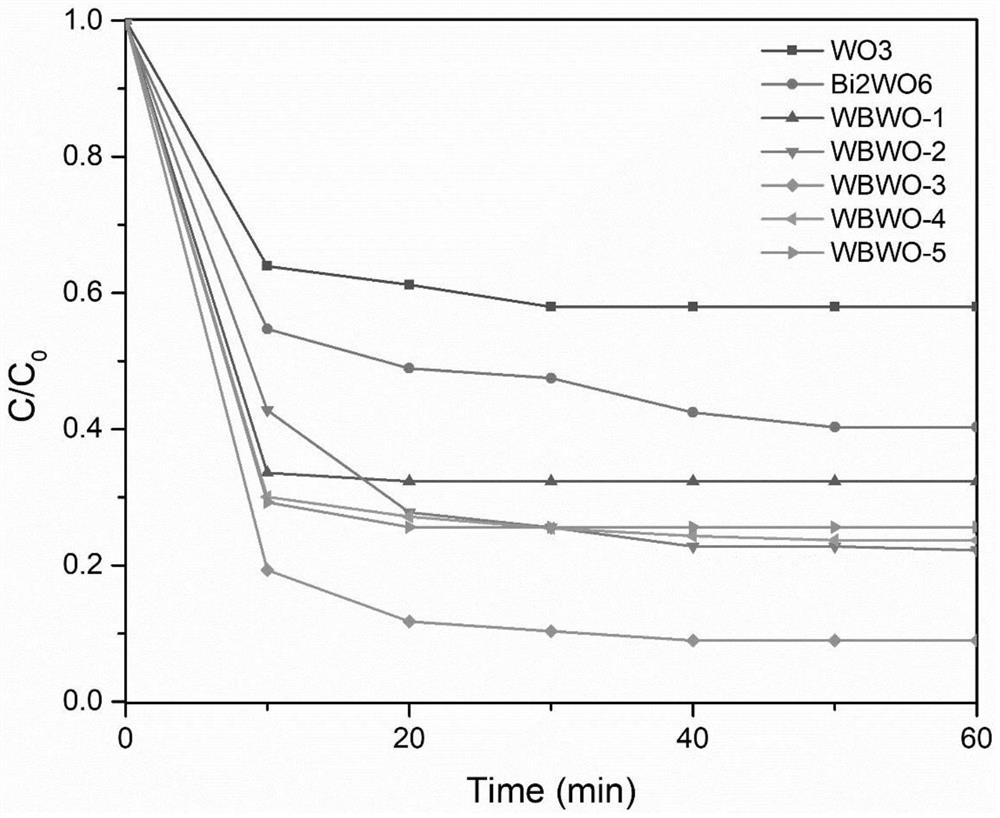

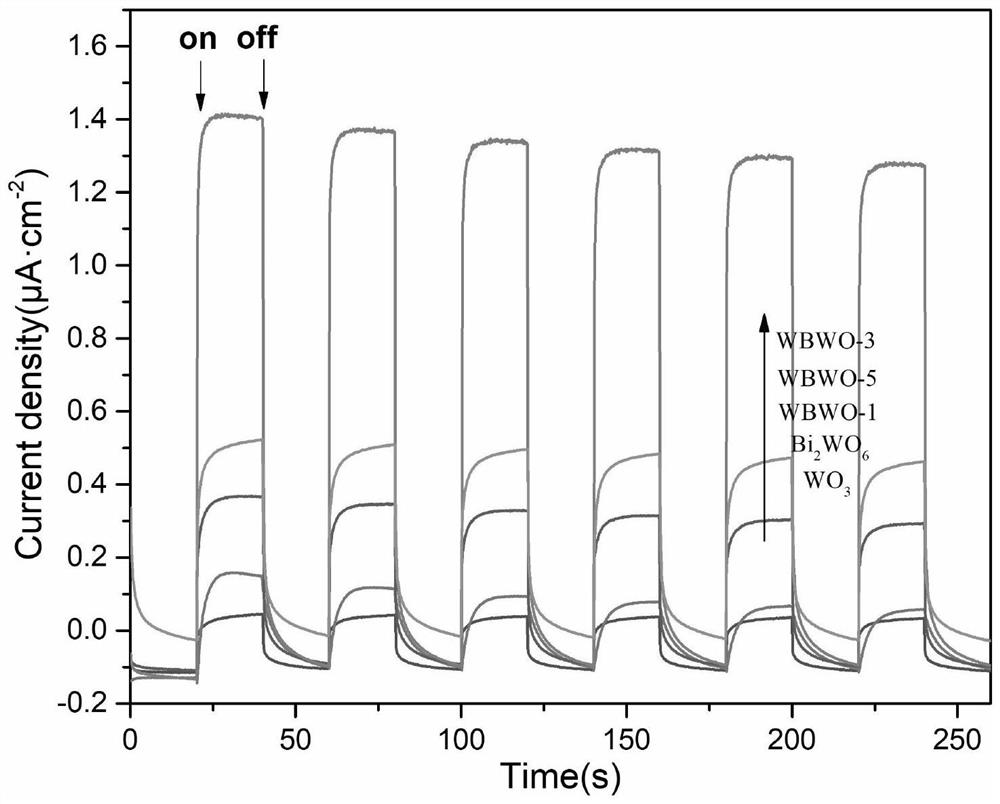

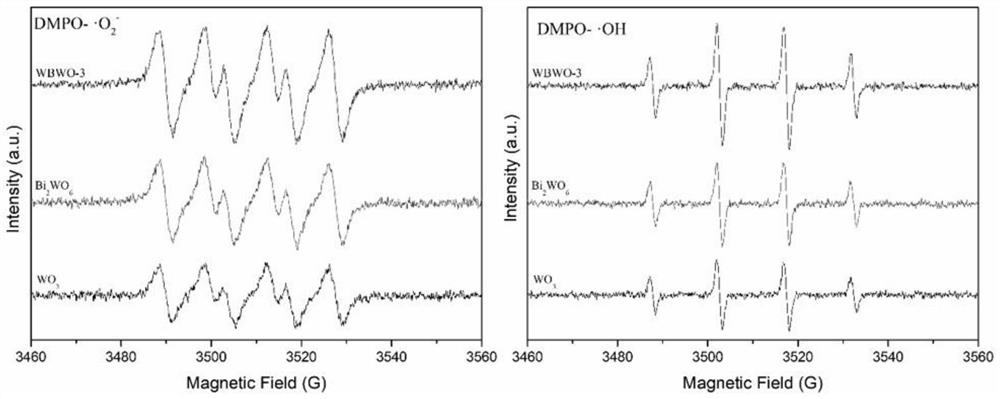

Preparation method of WO3/Bi2WO6 composite heterojunction material for photocatalytic degradation of toluene

PendingCN114832808AImprove crystallinityEasy to prepareGas treatmentDispersed particle separationPhotocatalytic degradationPhoto catalysis

The invention discloses a preparation method of a WO3 / Bi2WO6 composite heterojunction material for photocatalytic degradation of toluene, and belongs to the technical field of photocatalysis. The preparation method comprises the following steps: firstly, taking sodium tungstate and hydrochloric acid as raw materials, and preparing WO3 through the steps of hydrothermal reaction, washing, drying, high-temperature calcination and the like; uniformly mixing a sodium tungstate solution dissolved in deionized water and a bismuth nitrate solution dissolved in acetic acid, and adding the previously prepared WO3; the WO3 / Bi2WO6 heterojunction catalyst is prepared by carrying out ultrasonic treatment and solvothermal reaction on the mixed system, centrifuging, washing and drying. The prepared WO3 / Bi2WO6 catalyst has a matched energy band structure, a direct Z-type heterojunction can be formed, the WO3 / Bi2WO6 catalyst inhibits rapid recombination of electrons and holes under the condition of visible light, effective separation of the electrons and the holes is achieved, and meanwhile the maximum oxidation-reduction capacity of an original catalyst is reserved. The WO3 / Bi2WO6 prepared by the invention is applied to the field of photocatalysis of toluene for the first time, the activity of photocatalysis of toluene is high, and the removal rate of toluene within 60 minutes can reach 91%.

Owner:法尔曼环保科技(苏州)有限公司 +1

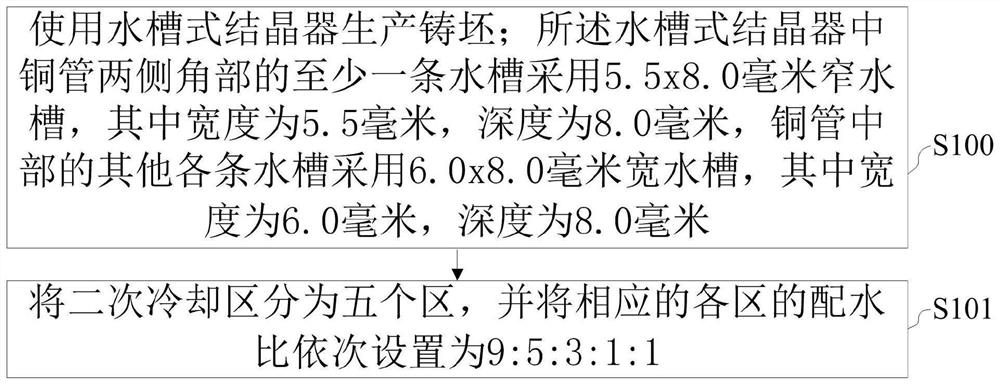

Defect-free casting blank production method for direct rolling

According to the defect-free casting blank production method for direct rolling, the improved efficient water tank type crystallizer is matched with the high-precision water jacket to improve the cooling uniformity of the copper pipe, guarantee is provided for increasing the pulling speed of a casting machine, and the defect-free casting blank production method for direct rolling is achieved through the improved special direct rolling water distribution model and the improved dense spraying nozzles which are matched at intervals. The casting speed of a casting machine is increased to 4.5 m / min from 2.8 m / min at most, the bleed-out rate of the casting machine is greatly reduced, the main components of the high-casting-speed casting powder are improved, and a guarantee is further provided for increasing the casting speed of the casting machine.

Owner:广西钢铁集团有限公司 +1

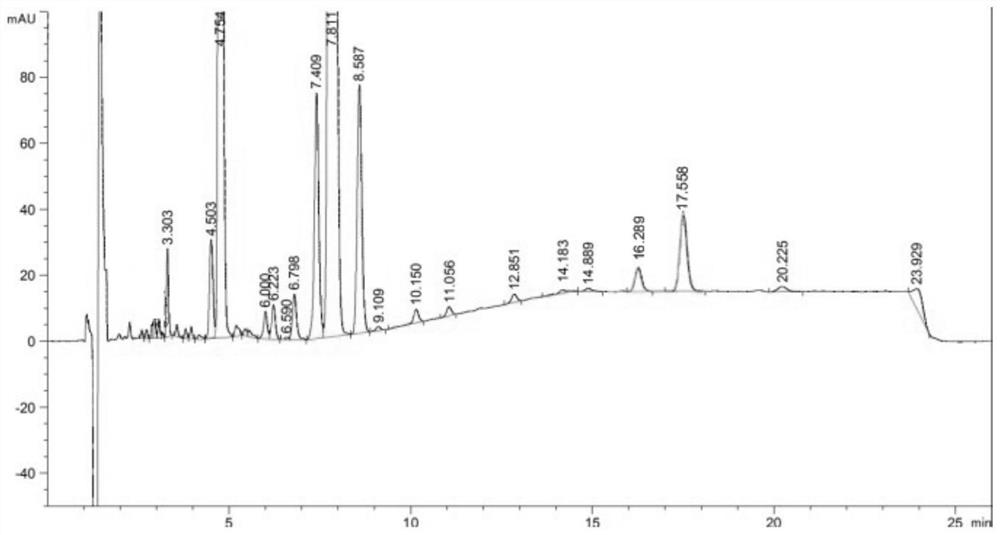

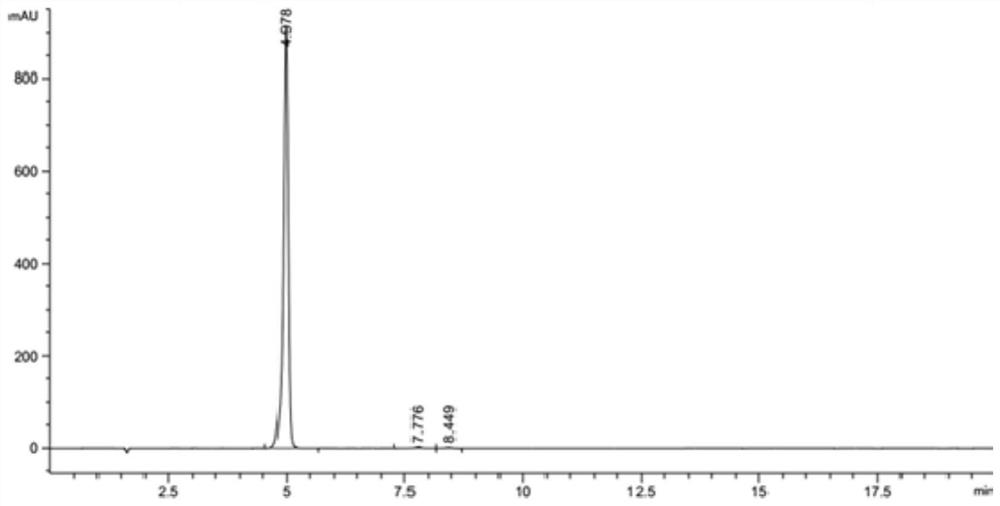

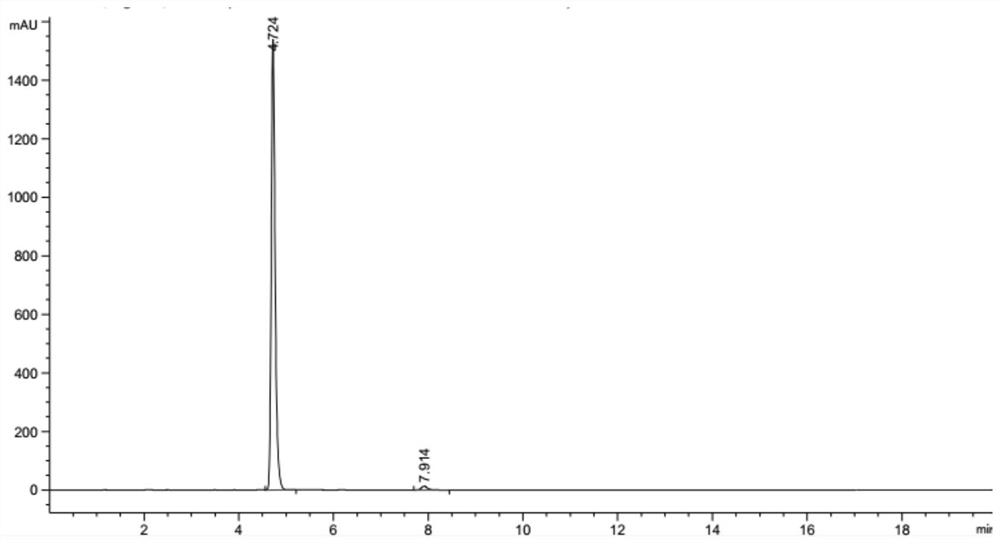

Method for preparing cannabidiol

PendingCN114057551AHigh extraction rateLess impuritiesOrganic chemistryOrganic compound preparationAlcoholSorbent

The invention discloses a method for preparing secondary cannabidiol, which at least comprises the following steps: a) pretreating a raw material containing industrial hemp to obtain a pretreated material; b) performing alcohol extraction on the pretreated material, concentrating an extracting solution I to obtain a concentrated solution, adding water for decarboxylation, and concentrating II to obtain a dry extract; c) mixing the dry extract and an adsorbent I to form a solid dispersion system, and performing solid-phase extraction to obtain a secondary cannabidiol primary product solution; d) subjecting the crude cannabidiol solution to concentration III, decoloration and crystallization so as to obtain the secondary cannabidiol. The preparation method is simple in process, high in product transfer rate, time-saving, labor-saving, large in treatment capacity, high in product purity and suitable for industrial large-scale production.

Owner:YUNNAN HEMPMON PHARMA CO LTD

Method for producing chromium sesquioxide through chromium-rich sludge

InactiveCN108275723AHigh purityQuality improvementChromium trioxideHydrofluoric acidChromium sesquioxide

The invention belongs to the technical field of environmental protection, and relates to the recycling of chromium-rich sludge, in particular to a method for producing chromium sesquioxide through chromium-rich sludge. The method comprises the following effective steps: a, firstly, washing and drying chromium-containing sludge; b, then, evenly grinding the dried chromium-containing sludge, transferring the chromium-containing sludge into a calcining kiln to directly heat the chromium-containing sludge, increasing the temperature of the chromium-containing sludge to 530 to 570 DEG C within 1.5to 2 hours, and then maintaining the temperature for 1 to 1.5 hours; c, transferring the chromium-containing sludge into a cooling kiln after heating is accomplished, reducing the temperature of the chromium-containing sludge to 60 to 90 DEG C, adding hydrochloric acid and water at the end of cooling, and uniformly stirring; d, transferring the uniformly stirred chromium-containing sludge into a filter press to perform filter pressing on the chromium-containing sludge, and washing filter residue to be neutral; e, adding water and hydrofluoric acid to the washed filter residue, stirring for 0.5hour, then transferring the filter residue into a filter press to perform filter pressing on the filter residue, and washing the filter residue to be neutral; f, then transferring the filter residueinto a high-temperature calcining kiln, performing burning and heating on the filter residue through coal gas, increasing the temperature of the filter residue to 1320 to 1400 within 2 hours, maintaining the temperature for 50 to 80 minutes, and then transferring the filter residue into the cooling kiln to reduce the temperature of the filter residue to below 40 DEG C, so as to obtain a finished product namely the chromium sesquioxide.

Owner:SHANDONG HUASHENG CHEM TECH

High-frequency and high-speed frequency testing system and method based on phase locking technique

ActiveCN102109552BImprove isolationImprove anti-interference abilityFrequency to phase shift conversionElectricityDisplay device

The invention discloses a high-frequency and high-speed frequency testing system based on a phase locking technique, comprising a standard signal source, a power supply device, a PCB (printed circuit board), a plurality of testing units arranged on the PCB and a data storage and display device, wherein the standard signal source is electrically connected with each testing unit respectively; each testing unit comprises a data acquisition module, a phase locking module and a data distribution module; the data acquisition module is used for acquiring the signal frequency of a tested product correspondingly; the phase locking module is used for carrying out phase comparison on the acquired signal frequency of the tested product and the standard signal source so as to obtain a comparison result, driving the corresponding tested product according to the comparison result and leading the phase of the tested product to be consistently locked with the phase of the standard signal source; and the data distribution module is used for outputting a phase value of the locked tested product to the data storage and display device for storage and display. The invention also discloses a high-frequency and high-speed frequency testing method based on the phase locking technique.

Owner:GUANGDONG DAPU TELECOM TECH CO LTD

Preparation method and system of trimethylsilylamine

ActiveCN113213439AEfficient responseMild conditionsEnergy based chemical/physical/physico-chemical processesNitrogen and non-metal compoundsTrisilylamineSide product

The invention discloses a preparation method and system of trimethylsilylamine, and the method comprises the following steps: carrying out a reaction on a mixed gas of N2, H2 and SiClxH4-x under the action of an electromagnetic field, wherein x is larger than or equal to 0 and smaller than or equal to 2. According to the method, efficient reaction of non-thermal plasma of nitrogen and hydrogen and chlorosilane is achieved, trimethylsilylamine is successfully prepared under the low-temperature and low-pressure conditions, the conditions are mild, and safety is high; and no solid by-product is produced, the product separation difficulty is low, solid waste treatment is not needed, the process is simple, the operability is high, and large-scale industrial production is facilitated.

Owner:ASIA SILICON QINGHAI +1

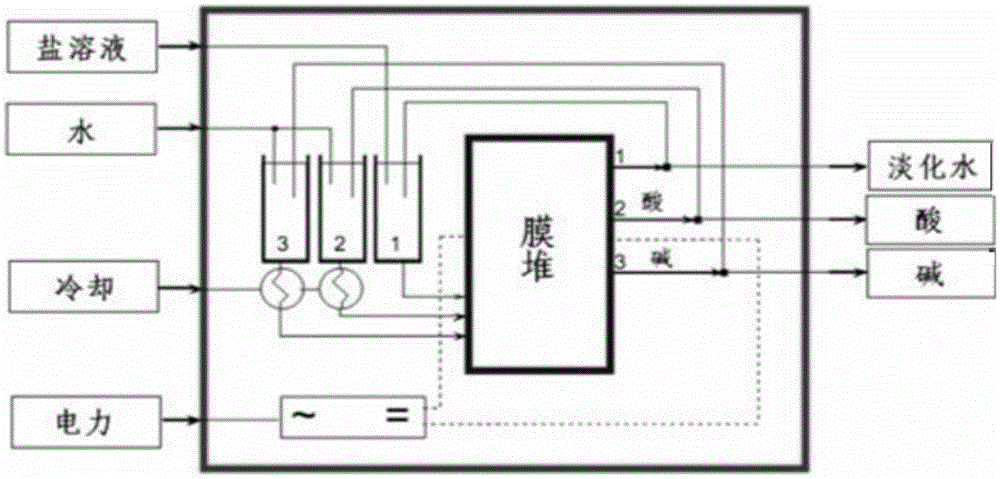

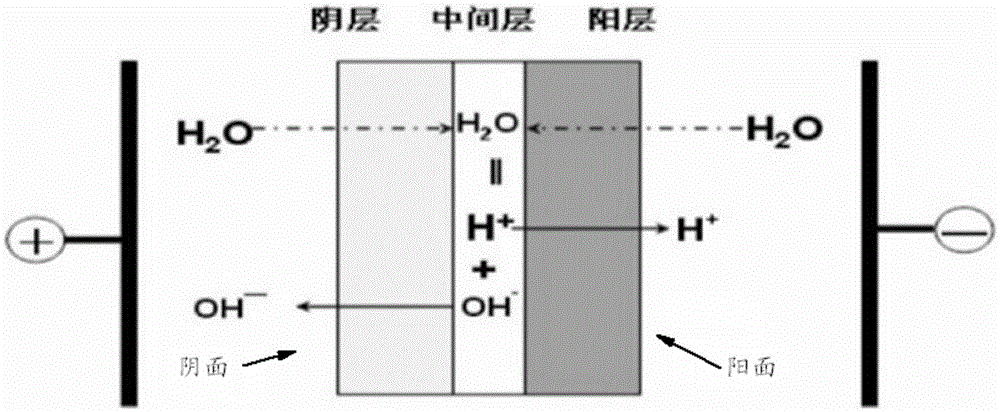

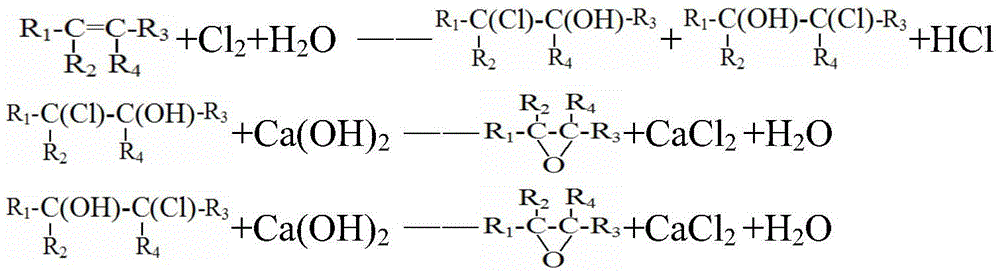

Preparation method for halogenohydrin and epoxide

ActiveCN106518589ASolve intractableSolve processing problemsDispersed particle separationHydroxy group formation/introductionHalogenEpoxide

The invention provides a preparation method for halogenohydrin and an epoxide. The method comprises the following steps: (1) halogenohydrination: adding H2O2 (or hydrogen peroxide), elemental halogen and an olefinic unsaturated compound with one or more C=C double bonds into a reaction apparatus for halogenohydrination so as to prepare halogenohydrin; (2) saponification: subjecting halogenohydrin prepared in the step (1) and a hydroxide of an alkali metal to saponification and carrying out separation so as to obtain the epoxides and a halogenated alkali metal salt; and (3) electrodialysis: subjecting the halogenated alkali metal salt obtained in the step (2) to bipolar membrane electrodialysis so as to obtain the hydroxide of the alkali metal and halogen hydride. The method has realizes high selectivity and yield in preparation of halogenohydrin or the epoxide, and greatly reduces discharge of waste water and waste residues.

Owner:JIANGXI SUKEER NEW MATERIAL

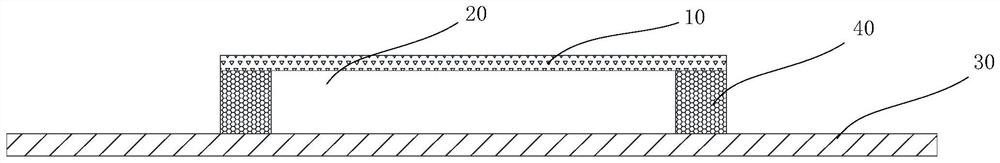

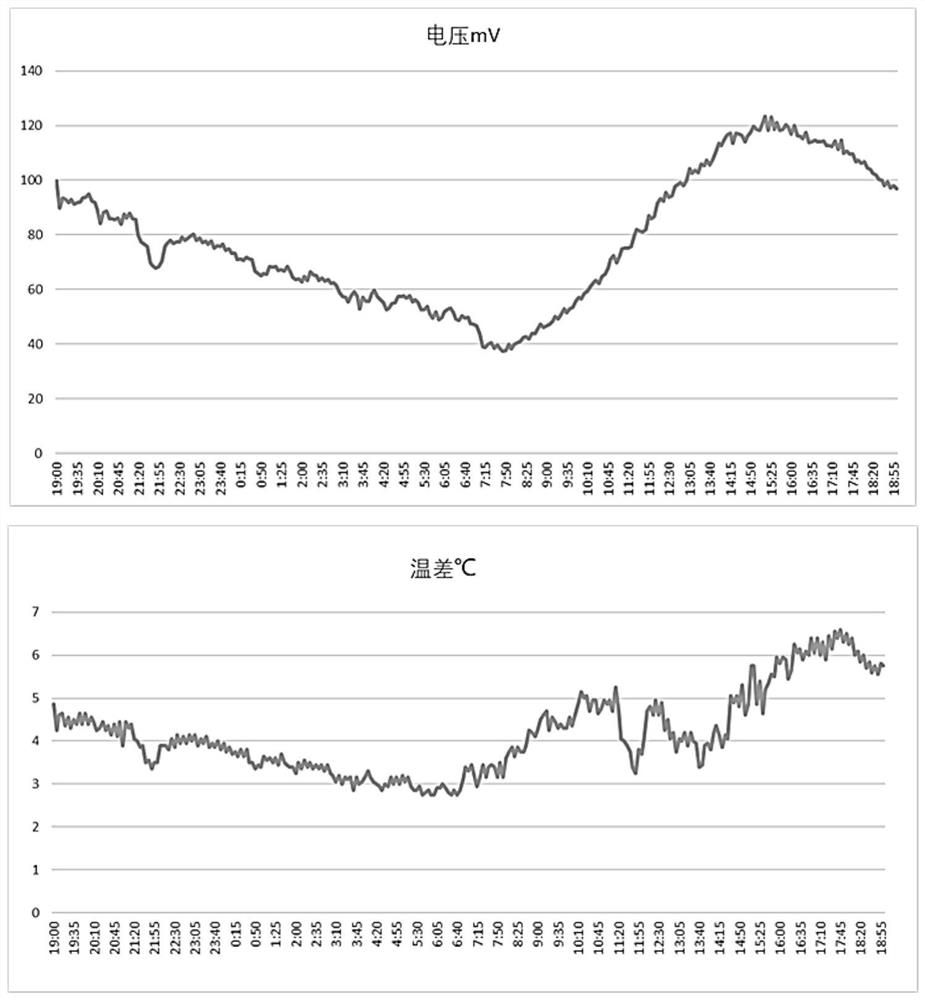

Thermoelectric power generation device based on radiation cooling and preparation method thereof

PendingCN114220905AIncrease power generation capacityReduce the greenhouse effectThermoelectric device manufacture/treatmentGenerators/motorsEngineeringMechanical engineering

The invention discloses a thermoelectric power generation device based on radiation cooling and a preparation method thereof, the device takes a sheet-shaped thermoelectric power generation element as a core, the cold end of the thermoelectric power generation element is attached to the lower part of a film-shaped radiation cooling element, and all-day cooling is realized by utilizing a space cold source through radiation cooling; the hot end of the temperature difference power generation element is attached to the plate-shaped temperature conduction element, the area of the temperature conduction element is large, the temperature conduction element can be arranged on any outdoor flat object, and in the day or sunny day, the temperature conduction element is used for absorbing solar radiation, heating the temperature difference power generation element and heating the surface near the temperature conduction element at the same time. In cloudy days or at night, the temperature conduction element can absorb nearby waste heat to heat the power generation sheet, so that the two sides of the thermoelectric power generation element can form a temperature difference in all weather / all seasons, and voltage is output to a load based on the Seebeck effect.

Owner:HEBEI UNIV OF TECH

Preparation method of catalyst for oxidative synthesis of folic acid from 6-R-tetrahydrofolic acid

PendingCN114029089AImprove oxidation reaction efficiencyHigh selectivityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsMANGANESE ACETATEPtru catalyst

The invention mainly relates to a preparation method of a supported composite catalyst for oxidative synthesis of folic acid from 6-R-tetrahydrofolic acid. The preparation method of the supported composite catalyst for oxidative synthesis of folic acid from 6-R-tetrahydrofolic acid comprises the following steps: suspending a certain amount of a SBA-15 molecular sieve in chloroform / ethanol (2: 1) solution accounting for 10 times of the volume of the SBA-15 molecular sieve, adding a certain amount of tetraphenylporphyrin, conducting dissolving while stirring, performing refluxing for 2 hours, adding a certain amount of ethanol / water (5: 1) solution of nickel acetate and manganese acetate, and continuing refluxing for 4 hours; and carrying out filtering, performing washing with distilled water three times, and carrying out drying in vacuum to obtain the supported composite catalyst. The catalyst is used in a reaction for synthesizing folic acid through hydrogen peroxide oxidation of 6-R-tetrahydrofolic acid, and catalytic effect is good. The catalyst accounting for 2% of the weight of the raw material is used, the purity of the refined folic acid product can reach 98.5% or above, and yield is 90% or above.

Owner:HARBIN UNIV OF SCI & TECH

A preparation method of polyethylene glycol and organic quicklime composite desiccant

ActiveCN106732386BGood hygroscopicityReduced responseOther chemical processesDispersed particle separationPolyethylene glycolNitrogen

The invention discloses a preparation method of a polyethylene glycol and organic quicklime composite drying agent. According to the preparation method, quicklime and ethanediol are introduced into a vacuum ball mill tank of a planetary ball mill, air in the vacuum ball mill tank is removed via pumping, nitrogen is introduced into the vacuum ball mill tank, grinding is carried out, and after grinding, an obtained product is taken out from the vacuum ball mill tank and is dried so as to obtain the polyethylene glycol and organic quicklime composite drying agent. The polyethylene glycol and organic quicklime composite drying agent is excellent in moisture absorption effect; reaction after water absorption is mild; safety is high; preparation process is simple; cost is low; no side product is generated; and the preparation method is friendly to the environment, and is suitable for large-scale production.

Owner:ZHEJIANG SCI-TECH UNIV

Tomato gray mold antagonistic strain B-04-glu

The invention provides a tomato gray mold antagonistic strain B-04-glu which is characterized by comprising four steps for the preparation: firstly, a strain of Bacillus cereus for high-efficient antagonistic gray mold is filtered from a soil sample infected by gray mold, and is named as B-04; secondly, bacteria solution which contains the B-04 bacteria is cultured; thirdly, ultrapure water, 1mM Hepes and electric shock buffer solution are used for washing in turn; fourthly, beta-1, 3-dextranase genes are transformed into the B-04 bacteria through electric shock method, and then the antagonistic strain B-04-glu is obtained. The antagonistic strain B-04-glu belongs to biological prevention and cure and does not contain compositions such as pyrilamine, pyrrole, acylamide and so on of chemical pesticide, thereby the antagonistic strain B-04-glu has the advantages of innocuity, no environmental pollution, difficult production of drug resistance, no residue, easy production, long effective period, strong curing ability, good application effect, safety on non-targeted organisms and so on and has wide application prospect.

Owner:SHANDONG UNIV OF TECH

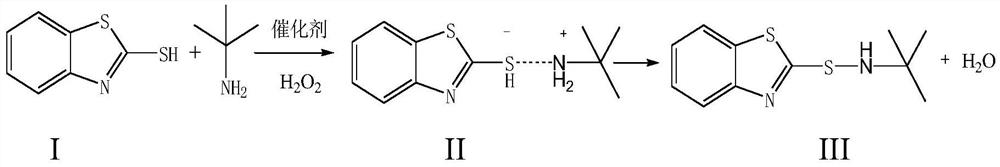

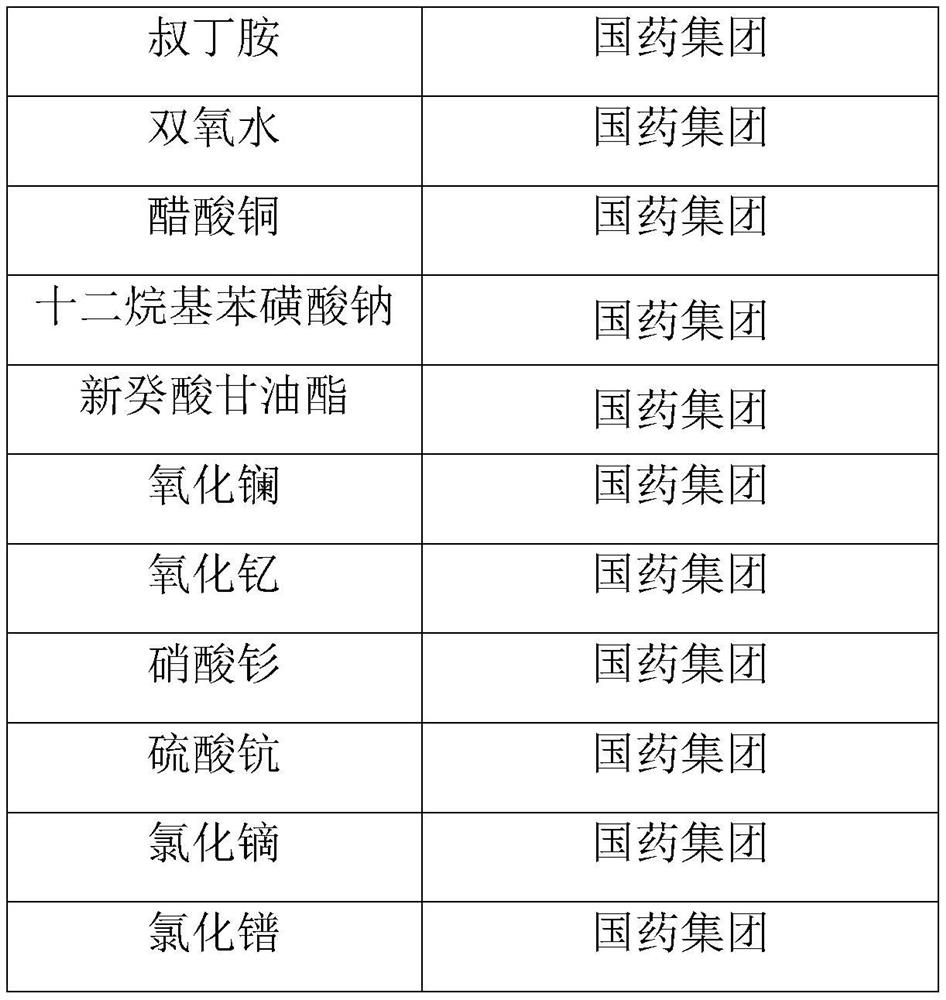

A kind of method for preparing rubber accelerator ns and rubber accelerator ns

The invention relates to a method for preparing rubber accelerator NS and the rubber accelerator NS in the field of rubber accelerator preparation. The method comprises the following steps: a. Oxidation process: Add hydrogen peroxide dropwise to the reaction raw material to oxidize until the end of the reaction to obtain a material; the reaction raw material includes a promoter M, tert-butylamine, and a rare earth compound catalyst; b. Post-treatment of the reactant: Recycle the material to obtain tert-butylamine; process the remaining material to obtain the finished accelerator NS. The molar ratio of the accelerator M, tert-butylamine, and hydrogen peroxide is 1: (5-15): (1-2); except for the hydrogen peroxide participating in the reaction, the method does not add water and organic solvents, which can effectively improve the reaction efficiency; The rare earth compound with high activity and high selectivity is used as the catalyst, the product has high purity, good color, almost no by-products and waste water are generated, the process is simple, clean and environmentally friendly.

Owner:BEIJING RED AVENUE INNOVA +1

A kind of preparation method of composite desiccant with polyethylene oxide and organic quicklime

ActiveCN106732446BGood hygroscopicityReduced responseOther chemical processesDispersed particle separationPolyethylene oxideEthylene oxide

The invention discloses a preparation method of a poly(ethylene oxide) and organic quicklime composite drying agent. According to the preparation method, quicklime is introduced into a vacuum ball mill tank of a planetary ball mill, air in the vacuum ball mill tank is removed via pumping, nitrogen is introduced into the vacuum ball mill tank, ethylene oxide is added, grinding is carried out, and after grinding, an obtained product is taken out from the vacuum ball mill tank and is dried so as to obtain the poly(ethylene oxide) and organic quicklime composite drying agent. The poly(ethylene oxide) and organic quicklime composite drying agent is excellent in moisture absorption effect; reaction after water absorption is mild; safety is high; preparation process is simple; cost is low; no side product is generated; and the preparation method is friendly to the environment, and is suitable for large-scale production.

Owner:ZHEJIANG SCI-TECH UNIV

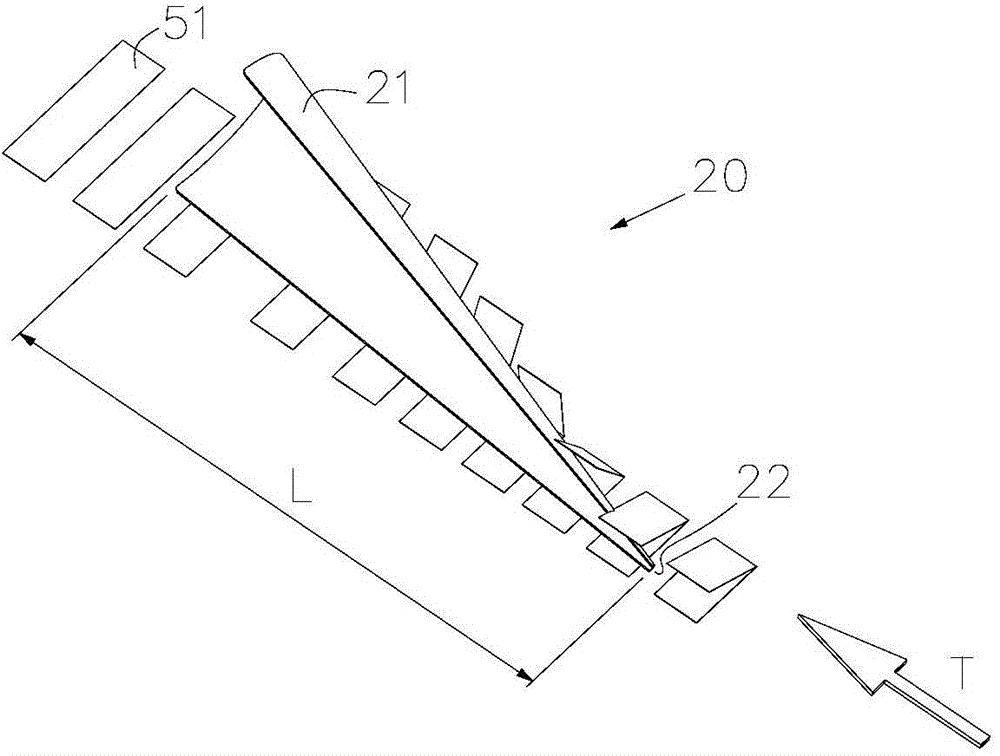

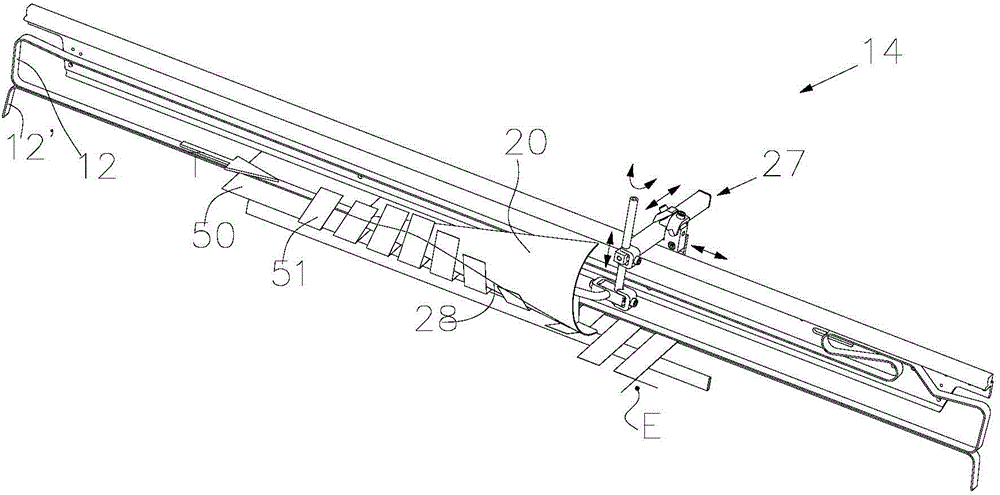

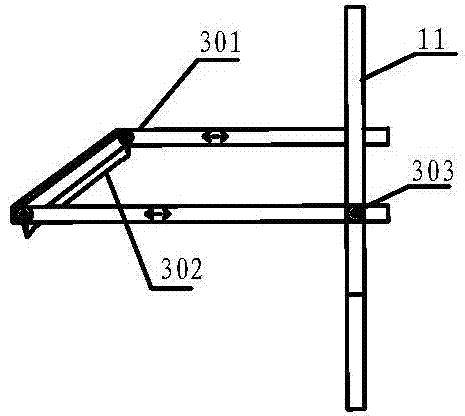

Unfolding device

InactiveCN104786554APrecise positioningPromote safe productionBox making operationsPaper-makingPaperboardBiomedical engineering

An unfolding device is used to unfold a folded face of a blank of a folding box, and is suitable for paper, card paper or a paperboard as the blank of the folding box. A fixed unfolding body is disposed in the unfolding device, and the unfolding body is installed a scope of a conveying device conveying the blank. The unfolding device is characterized in that the unfolding body is a cone or a pyramid especially a side face of a cone or a pyramid. The unfolding device is advantageous in that the folding box and the unfolding device can perform long-term contact through a pyramidal unfolding device model not according to the shape of the blank so that safe folding without loss can be performed.

Owner:MASTERWORK GROUP CO LTD

A kind of engineering bacterium and the method for preparing (3r, 5r) 6-cyano-3,5-dihydroxyhexanoic acid tert-butyl ester

ActiveCN104087547BSimple production processNo productionBacteriaMicroorganism based processesCatalytic effectMicrobiology

The invention discloses an engineering bacterium and a method for preparing tert-butyl (3R, 5R) 6-cyan-3, 5-dyhydroxyl hexanoate. The engineering bacterium comprises a host cell and a target gene transformed into the host cell, wherein the target gene is a halohydrin dehalogenase gene. The method comprises the following steps: culturing the engineering bacterium and inducing the halohydrin dehalogenase gene to express; centrifuging to take the cell; resuspending by a buffer liquid to obtain a resting cell suspension; adding tert-butyl (3R, 5S) 6-chloro-3, 5-dyhydroxyl hexanoate and NaCN to the resting cell suspension for reacting, and after reaction, separating and purifying a reaction liquid to obtain a product. Through the catalytic effect of the enzyme, the method disclosed by the invention simplifies the production process of tert-butyl (3R, 5R) 6-cyan-3, 5-dyhydroxyl hexanoate, is free from a lot of reaction byproducts and lowers the production cost.

Owner:ZHEJIANG UNIV

Method and machine for making brushes

Owner:ZAHORANSKY AG

Automatic production equipment and method of rubber powder polystyrene particle insulation board

InactiveCN105573280BImprove cutting accuracyImprove yieldTotal factory controlProgramme total factory controlProduction lineMaterials preparation

The invention discloses an automatic production equipment and method for rubber powder polystyrene particle insulation boards. The device includes a control device, a lining board laying device, a material preparation device, a board conveyor belt, a leveling device, a cutting device, and a storage device for finished boards; The liner laying device is arranged at the entrance of the board conveyor belt; the material preparation device is arranged above the front end of the board conveyor belt; the material laying device is arranged above the board conveyor belt and behind the material preparation device; the cutting device is arranged at Above the rear end of the plate conveyor belt; the finished plate storage device is arranged at the exit of the plate conveyor belt. The present invention controls each device through the control device, so that each link can be automatically produced in an orderly manner according to the process control, forming a set of fully automatic rubber powder polystyrene particle insulation board production line, which not only improves the rubber powder polystyrene particle heat preservation board. The production efficiency is high, and the cutting precision of the plate is high, the finished product rate of the finished plate is high, and there is no production waste.

Owner:山东美鹰食品设备有限公司

Passive overpressure relief valve

ActiveCN104088845BHigh work pressureGuaranteed reliabilityServomotor componentsHigh pressureOil pressure

Owner:ZHUZHOU WENJIA IND

A preparation method of polyacrylic acid and organic quicklime composite desiccant

InactiveCN106552605BHigh purityUniform particlesGas treatmentOther chemical processesDesiccantNitrogen

The invention discloses a preparing method for a polyacrylic acid and organic quick lime composite desiccant. Quick lime and crylic acid are added into a vacuum ball-milling tank of a planet ball mill, air in the vacuum ball-milling tank is pumped away, nitrogen is inflated in for ball milling, an obtained product is taken out to be dried after milling is finished, and the polyacrylic acid and organic quick lime composite desiccant is prepared. The prepared polyacrylic acid and organic quick lime composite desiccant is good in moisture absorption effect, an reaction is alleviated after water absorption, the safety is good, the process is simple, the cost is low, no by-products are produced, environmental protection and energy saving are achieved, and the preparing method is suitable for mass production.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com