Non-dewatering production method of quick-hardening furan resin

A production method and technology of furan resin, applied in the field of casting, can solve problems such as difficult wastewater treatment, and achieve the effects of reducing energy consumption, reducing moisture, and reducing material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

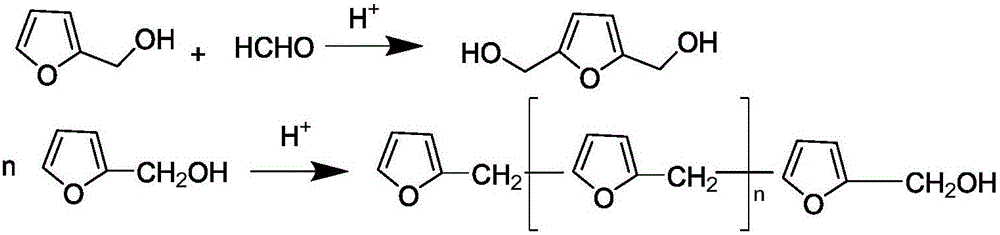

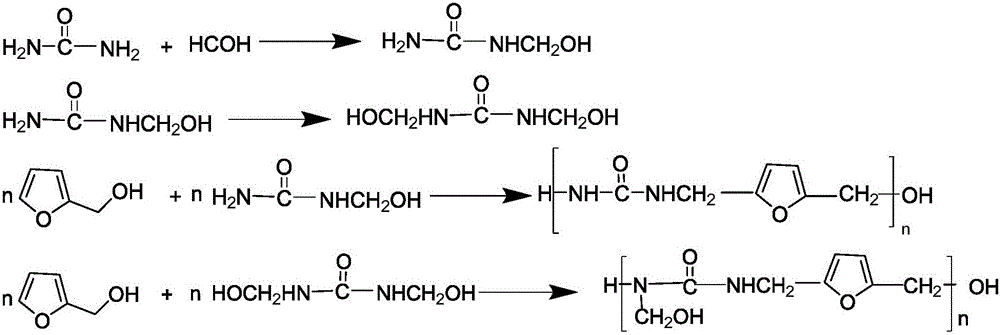

Method used

Image

Examples

Embodiment 1

[0024] Add 50 parts of formaldehyde, 100 parts of paraformaldehyde, and 180 parts of furfuryl alcohol into the reaction kettle, stir evenly, add 0.01 parts of propionic acid, heat to 100°C, keep the temperature for 3 hours; then continue to add 50 parts of urea to the reaction kettle, The reaction temperature is increased to 105°C, and the reaction is kept for 50 minutes; 400 parts of furfuryl alcohol are continuously added, and the material is discharged while stirring and cooling to room temperature. Wherein, the parts of each raw material component are parts by weight.

Embodiment 2

[0026] Add 60 parts of formaldehyde, 90 parts of paraformaldehyde, and 200 parts of furfuryl alcohol into the reaction kettle, stir well, add 0.02 parts of propionic acid, heat to 102°C, keep warm for 3.5 hours; then continue to add 60 parts of urea to the reaction kettle, The reaction temperature is increased to 106°C, and the reaction is kept for 55 minutes; 500 parts of furfuryl alcohol are continuously added, and the temperature is lowered to room temperature with stirring to discharge. Wherein, the parts of each raw material component are parts by weight.

Embodiment 3

[0028] Add 100 parts of formaldehyde, 80 parts of paraformaldehyde, and 250 parts of furfuryl alcohol into the reactor, stir evenly, add 0.04 parts of propionic acid, heat to 104°C, keep the temperature for 4 hours; then continue to add 80 parts of urea to the reactor, The reaction temperature is increased to 108°C, and the reaction is kept for 60 minutes; 600 parts of furfuryl alcohol are continuously added, and the temperature is lowered to room temperature with stirring to discharge. Wherein, the parts of each raw material component are parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com