Preparation method of WO3/Bi2WO6 composite heterojunction material for photocatalytic degradation of toluene

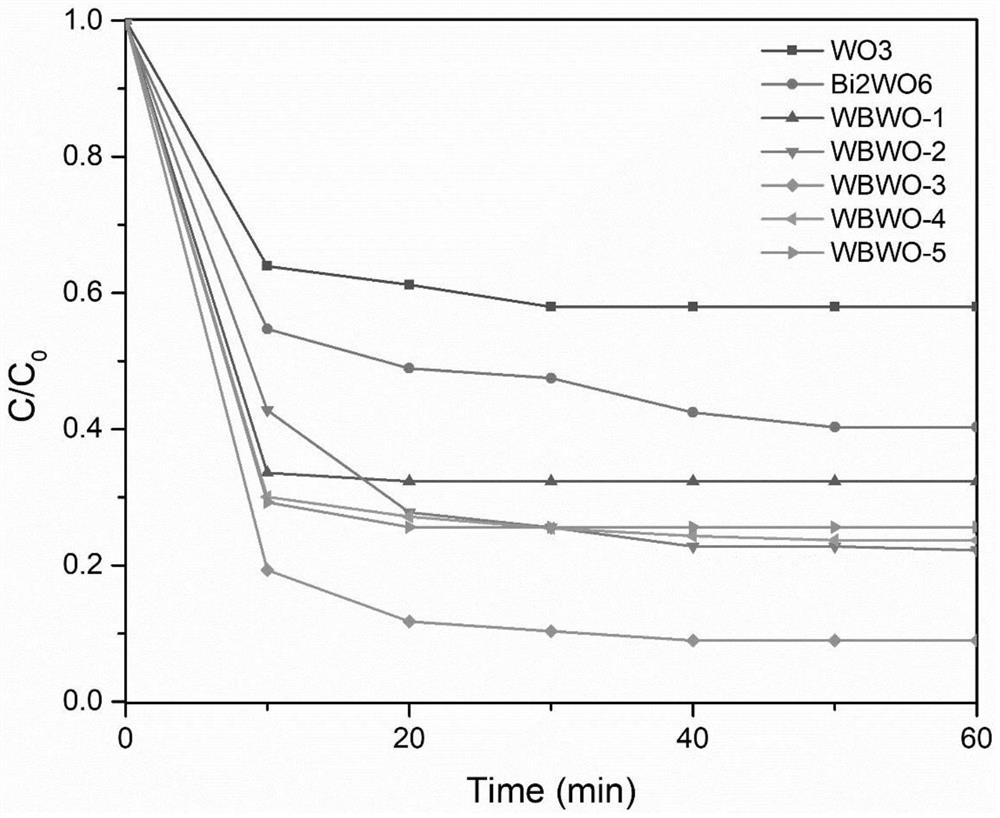

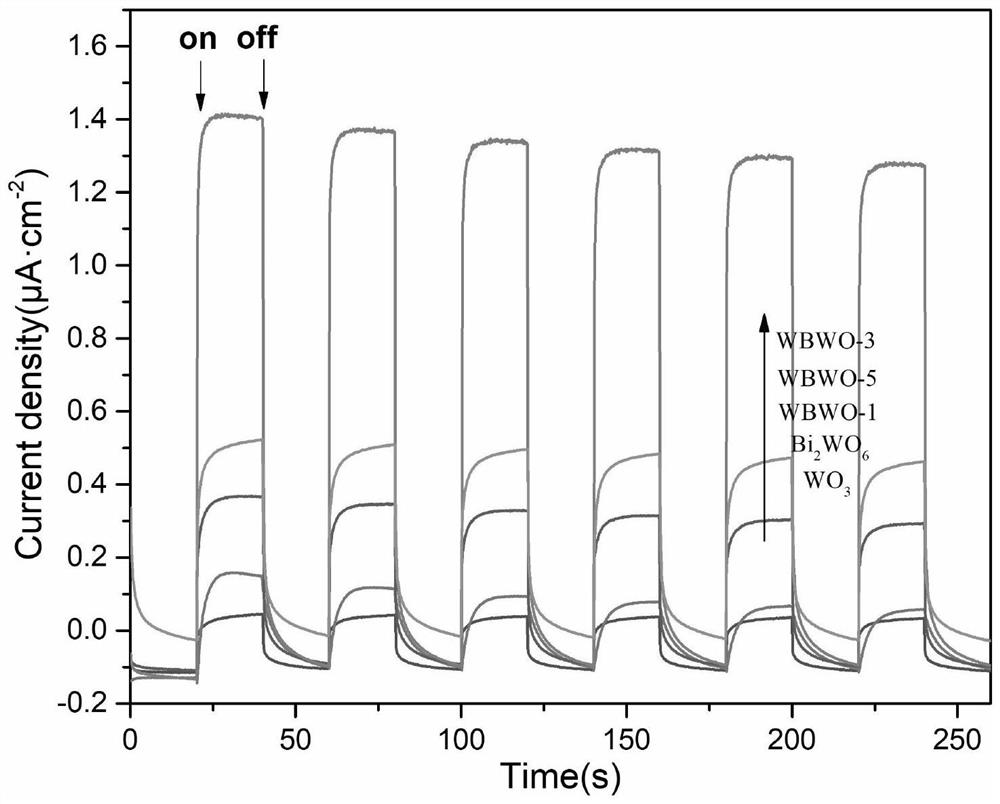

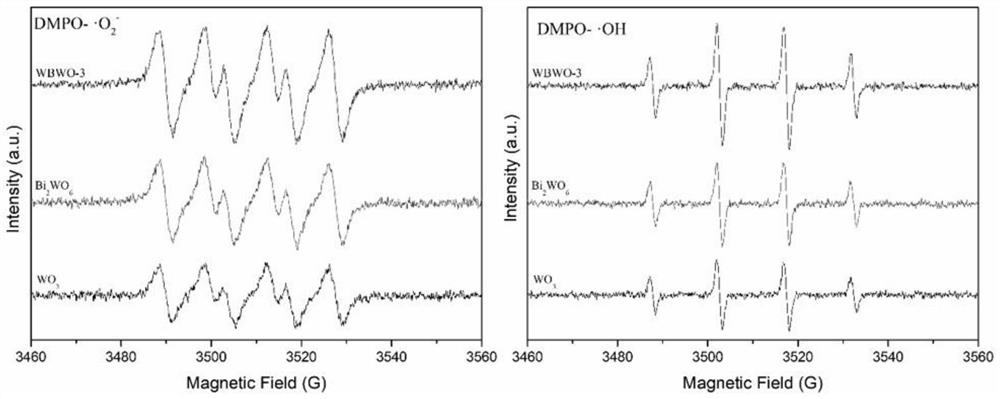

A composite heterojunction and photocatalysis technology, applied in the field of photocatalysis, can solve the problems of low separation efficiency of photogenerated electrons and holes, low toluene activity, low photocatalytic activity, etc., to enhance the utilization rate of light energy, and the preparation method. Simple, highly active effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a WO 3 / Bi 2 WO 6 The preparation method of the catalyst, the preparation method specifically comprises the following steps:

[0025] (1) Weigh 12g of sodium tungstate (Na 2 WO 4 ·2H 2 O) was dissolved in 80 ml of deionized water, and after continuous magnetic stirring for 30 min, 80 ml of 8M hydrochloric acid solution was slowly added dropwise to form a yellow dispersion. Subsequently, the mixed system was transferred to a Teflon-lined stainless steel autoclave with a volume of 200 ml. The autoclave was sealed and placed in an oven at 100 °C for 24 h. The obtained yellow substance was washed with deionized water and absolute ethanol for three times and centrifuged, dried at 80 °C for 12 h, and then calcined at 400 °C for 4 h to obtain WO 3 powder.

[0026] (2) 1 mmol Na 2 WO 4 ·2H 2 O was dissolved in 120 mL of deionized water and stirred for 30 min to obtain solution A, and 2 mmol of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) was dissolved in 10 mL of glacial...

Embodiment 2

[0028] a WO3 / Bi 2 WO 6 The preparation method of the catalyst, the preparation method specifically comprises the following steps:

[0029] (1): Weigh 12g of sodium tungstate (Na 2 WO 4 ·2H 2 O) was dissolved in 80 ml of deionized water, and after continuous magnetic stirring for 30 min, 80 ml of 8M hydrochloric acid solution was slowly added dropwise to form a yellow dispersion. Finally, the mixed system was transferred to a Teflon-lined stainless steel autoclave with an inner volume of 200 ml. The autoclave was sealed and placed in an oven at 100°C for 24 hours. The obtained yellow substance was washed with deionized water and absolute ethanol for three times and centrifuged, dried at 80 °C for 12 h, and then calcined at 400 °C for 4 h to obtain WO 3 powder.

[0030] (2): 1 mmol Na 2 WO 4 ·2H 2 O was dissolved in 120 mL of deionized water and stirred for 30 min to obtain solution A, and 2 mmol of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) was dissolved in 10 mL of gl...

Embodiment 3

[0032] a WO 3 / Bi 2 WO 6 The preparation method of the catalyst, the preparation method specifically comprises the following steps:

[0033] (1): Weigh 12g of sodium tungstate (Na 2 WO 4 ·2H 2 O) was dissolved in 80 ml of deionized water, and after continuous magnetic stirring for 30 min, 80 ml of 8M hydrochloric acid solution was slowly added dropwise to form a yellow dispersion. Finally, the mixed system was transferred to a Teflon-lined stainless steel autoclave with an inner volume of 200 ml. The autoclave was sealed and placed in an oven at 100°C for 24 hours. The obtained yellow substance was washed with deionized water and absolute ethanol for three times and centrifuged, dried at 80 °C for 12 h, and then calcined at 400 °C for 4 h to obtain WO 3 powder.

[0034] (2): 1 mmol Na 2 WO 4 ·2H 2 O was dissolved in 120 mL of deionized water and stirred for 30 min to obtain solution A, and 2 mmol of bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) was dissolved in 10 mL of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com