Preparation method of oxidation-resistant PPS filter material and prepared modified PPS fiber

A technology of filter material and production method, applied in the chemical characteristics of fibers, melt spinning, stretch spinning, etc., can solve the problems of decreased performance of fiber products, uneven film formation on the surface of PPS fibers, and improved crystallinity, The effect of good thermal dimensional stability, good high temperature resistance and oxidant corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

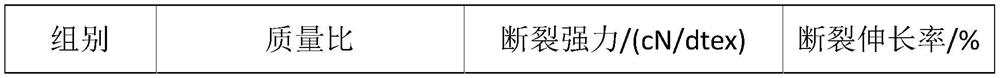

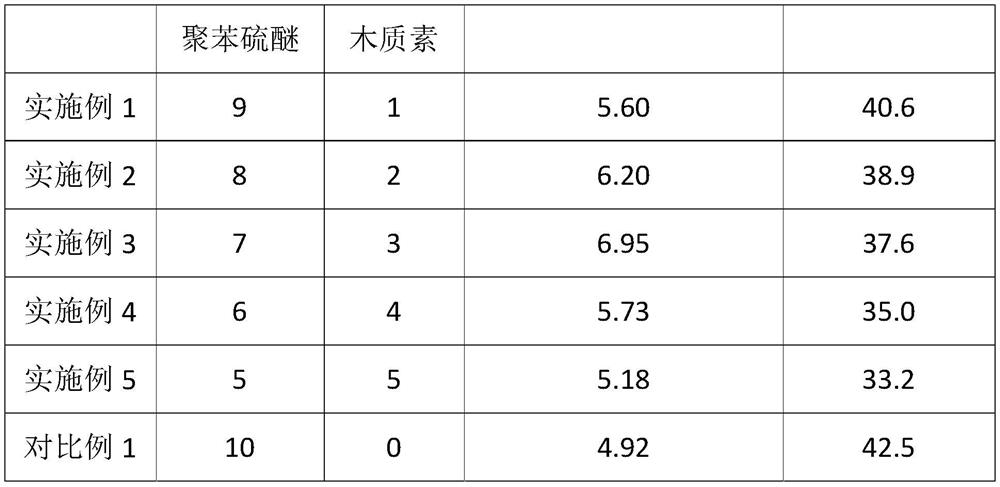

Embodiment 1

[0029] A kind of manufacture method of anti-oxidation PPS filter material, comprises the following steps:

[0030] (1) Preparation of modified PPS resin

[0031] According to the mass ratio of 1:9, polyphenylene sulfide resin slices and lignin are mixed, heated and melted, extruded and granulated, and dried to obtain a modified polyphenylene sulfide resin; the temperature of heating and melting is 200°C , the drying temperature is 70°C;

[0032] (2) Melt spinning

[0033] The modified polyphenylene sulfide resin prepared in step (1) is spun in a melt spinning machine, and passed through a screw extruder, a melt filter, a spinning box and components, wherein the modified polyphenylene sulfide resin is put into The temperature of zone 1-4 of the screw extruder for phenylene sulfide resin slices is 290°C / 305°C / 315°C / 315°C respectively to obtain a spinning melt. The spinneret is ejected, the temperature of the spinning box is 320°C, the ring blowing nitrogen is 325Pa, and the s...

Embodiment 2

[0037] The difference between this example and Example 1 is that the mass ratio of polyphenylene sulfide resin slices to lignin is 4:1. Other steps and processing parameter are identical with embodiment 1.

Embodiment 3

[0039] The difference between this example and Example 1 is that the mass ratio of polyphenylene sulfide resin slices to lignin is 7:3. Other steps and processing parameter are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com