Method for preparing supercapacitor material by alkaline hydrolysis on cobalt aluminum double metal hydroxide

A supercapacitor and hydroxide technology, applied in chemical instruments and methods, hybrid/electric double layer capacitor manufacturing, cobalt compounds, etc., can solve the problems of active material detachment, electrode conductive network damage, electrode performance degradation, etc., and achieve crystallization Enhanced performance, increased charge and discharge mass specific capacitance, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

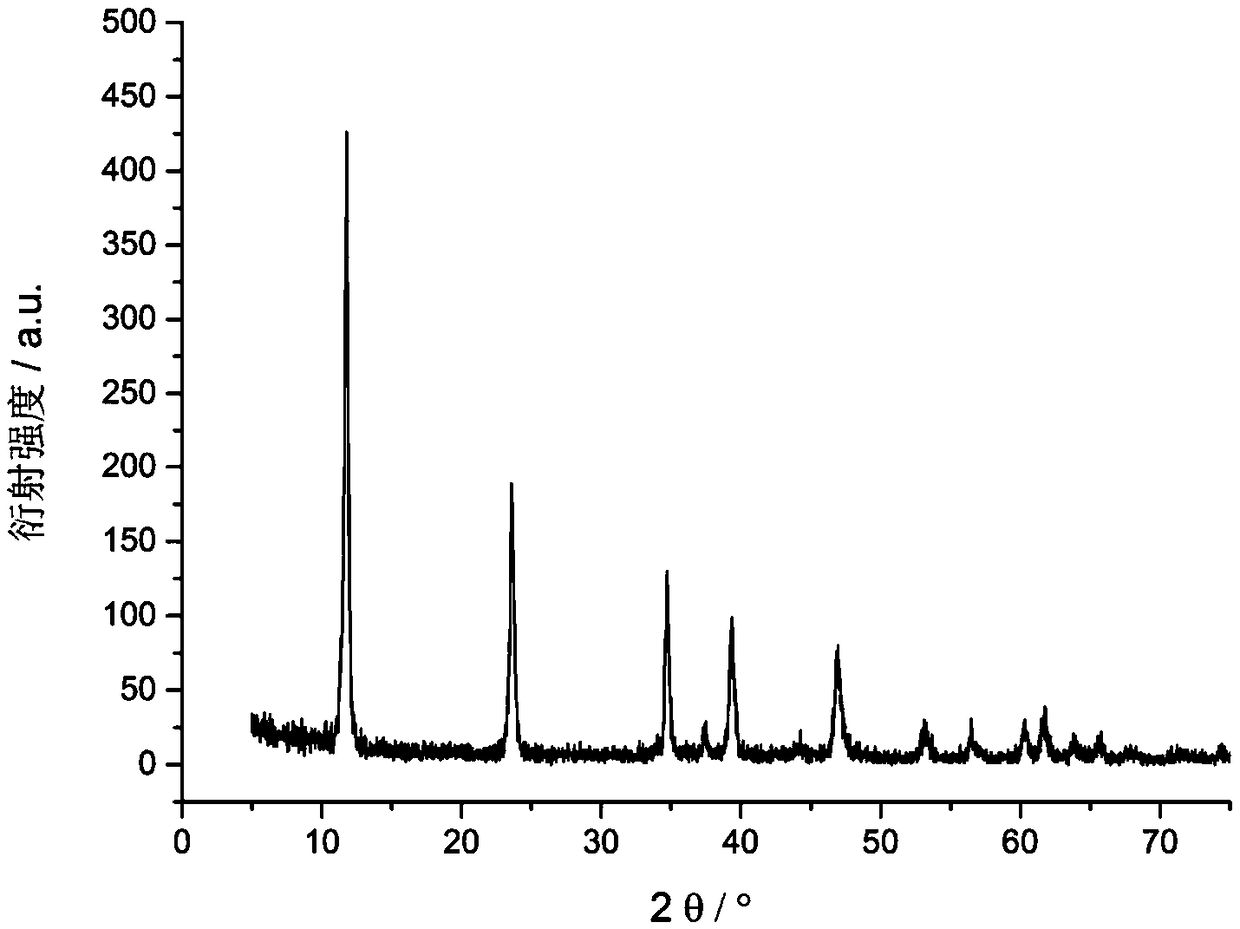

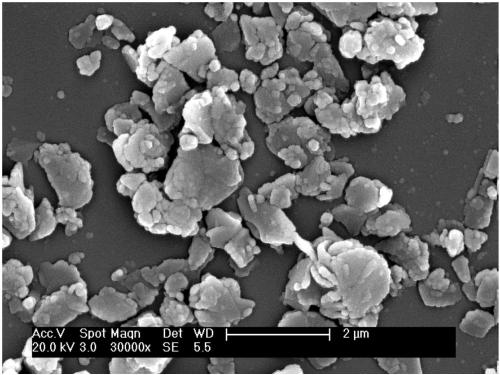

[0032] Dissolve 1.16 grams of cobalt nitrate, 1.50 grams of aluminum nitrate (the molar ratio of cobalt to aluminum is 1:1) and 5.0 grams of urea in 150 ml of distilled water, raise the temperature to 100 ° C, keep stirring for 10 hours, filter, wash and dry That is, 0.60 g of pink cobalt-aluminum double hydroxide solid was obtained with a yield of 80%. figure 1 It is the XRD spectrum of the cobalt, aluminum double metal hydroxide that embodiment 1 obtains. The material has the structural characteristics of layered hydroxides. figure 2 It is the SEM spectrum of the cobalt, aluminum double metal hydroxide that embodiment 1 obtains. As can be seen from the figure, the material is in the form of flakes.

Embodiment 2

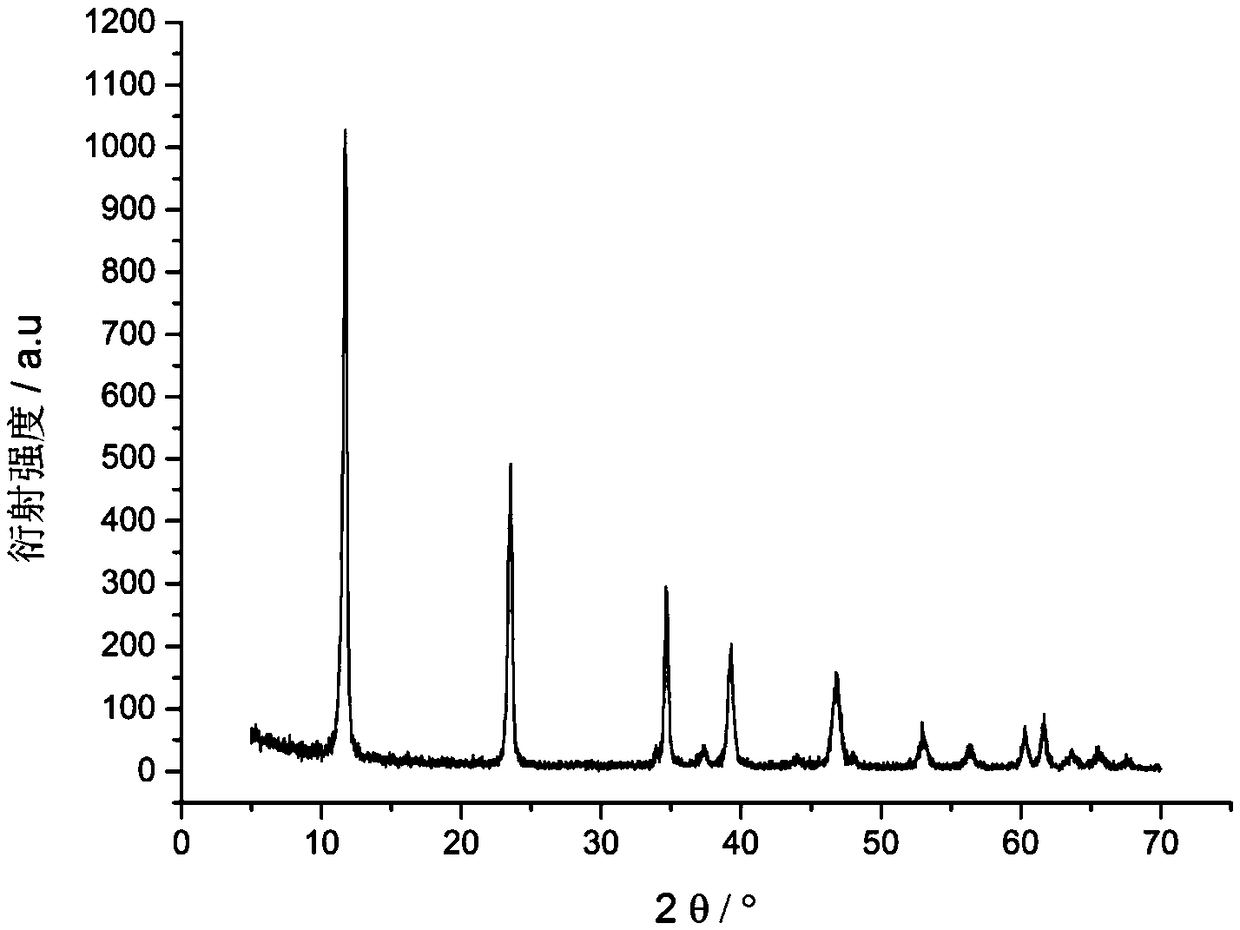

[0034] 10.0 g of cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and 12.9 grams of aluminum chloride hydrate (AlCl 3 ·6H 2 O) Mix, add 30.0 g of hexamethyleneimine into 500 ml of distilled water at room temperature; under rapid stirring, keep warm at 120° C. for 2 days, filter, wash with water three times, wash with ethanol three times, and dry to obtain a solid 0.67 g; about 67% yield. image 3 The XRD spectrum of cobalt, aluminum double metal hydroxide obtained by embodiment 2.

Embodiment 3

[0036] The implementation process of the alkaline hydrolysis process of the cobalt-aluminum double metal hydroxide obtained in embodiment 1 is: get 0.50 gram of solid product respectively, be placed in 20 milliliters of containers, add 16 milliliters of concentrations and be the potassium hydroxide of 7 moles per liter solution, stirred evenly, sealed, and placed in an environment of 60° C. for 2 hours; respectively cooled, filtered, washed three times with water and three times with ethanol, and dried to obtain 0.35 g of solids with a yield of 70%. Figure 4 For the XRD collection of supercapacitor materials obtained after alkali hydrolysis by embodiment 3. The results show that after alkaline hydrolysis treatment, the material still maintains the structural characteristics of layered hydroxide (LDH), and the crystallinity is enhanced. Figure 5 Obtain the SEM spectrum of supercapacitor material after the alkaline hydrolysis that is obtained by embodiment 3. It can be seen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com