Prepn process of lithium aluminate substrate material

A technology of lithium aluminate substrate and lithium nitrate, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of volatile Li, poor thermal stability, and complicated preparation process, so as to promote the combination Separation, improvement of crystallinity, and the effect of inhibiting volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

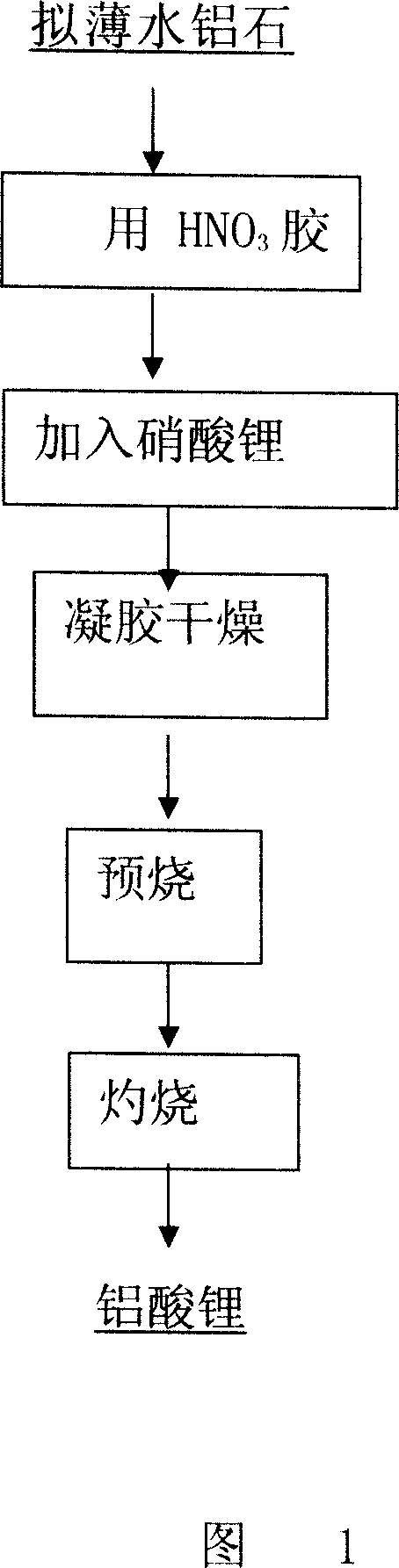

[0011] The preparation method of the lithium aluminate substrate material of the present invention adopts the sol-gel method, which mainly includes several steps: preparation of alumina sol, preparation of aluminum-lithium xerogel powder, pre-calcination, infiltration, and burning

[0012] Said sol-gel method is that the purity is 97-99%, and the pseudo-boehmite whose crystal grain size is 80-100nm compares boehmite according to mass: water=5-10%: 95-90% Ratio, adjust the pH of the solution to 1-3 with a 30% nitric acid solution to obtain an alumina sol.

[0013] Said sol-gel method is to add lithium nitrate with a purity of 99.999% into the alumina sol at a molar ratio of lithium nitrate:pseudoboehmite=1.1-1.2:1; mechanically stir for 6-12 After standing still for an hour, aluminum lithium gel was obtained.

[0014] In the sol-gel method, the aluminum-lithium gel is dried in a constant temperature oven at a temperature of 110°C-120°C for 48-96 hours to obtain aluminum-lithiu...

example 1

[0020] Example 1 is carried out according to the process flow described in Fig. 1. According to the ratio of mass comparison boehmite: water=5%: 95%, take by weighing pseudo-boehmite with a purity of 99%, add deionized water, stir at room temperature, and adjust with a concentration of 30% nitric acid solution The pH of the solution is 3 to obtain alumina sol; according to the ratio of lithium nitrate in molar ratio:pseudoboehmite=1.1:1, lithium nitrate with a purity of 99.999% is weighed and added to the alumina sol, mechanically stirred for 6 hours and left to stand , to obtain an aluminum-lithium gel; the gel is placed in a constant temperature oven for drying, the setting temperature is 110 ° C, and the time is 96 hours to obtain an aluminum-lithium xerogel powder; the aluminum-lithium xerogel powder is placed in a corundum crucible, Without a cover, the temperature is 600°C, the time is 2 hours, and the pre-burned powder is obtained; take another corundum crucible with a ...

example 2

[0022] Example 2 is carried out according to the process flow described in Fig. 1. According to the mass comparison boehmite: the ratio of water=8%:92%, take the pseudo-boehmite with a purity of 98%, add deionized water, stir at room temperature, and adjust with a 30% nitric acid solution Solution pH=2, obtain alumina sol; According to the ratio of molar ratio lithium nitrate:pseudoboehmite=1.15:1, take lithium nitrate with a purity of 99.999% and add it to alumina sol, mechanically stir for 8 hours and then let it stand , to obtain an aluminum-lithium gel; the gel is placed in a constant temperature oven for drying, the setting temperature is 110 ° C, and the time is 72 hours to obtain an aluminum-lithium xerogel powder; the aluminum-lithium xerogel powder is placed in a corundum crucible, Without a cover, the temperature is 700°C, and the time is 3 hours, to obtain pre-burned powder; take another corundum crucible with a cover, fill it with lithium nitrate, cover it, burn it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com