Method of increasing perovskite film crystallinity

A technology of crystallinity and perovskite, applied in semiconductor devices, electrical components, photovoltaic power generation, etc., to achieve the effects of improving flatness, reducing preparation costs, and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

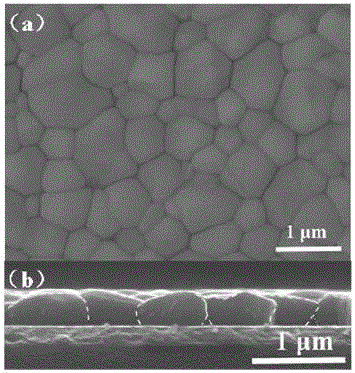

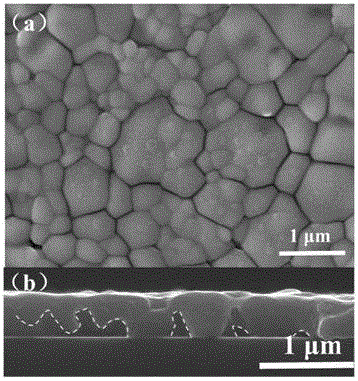

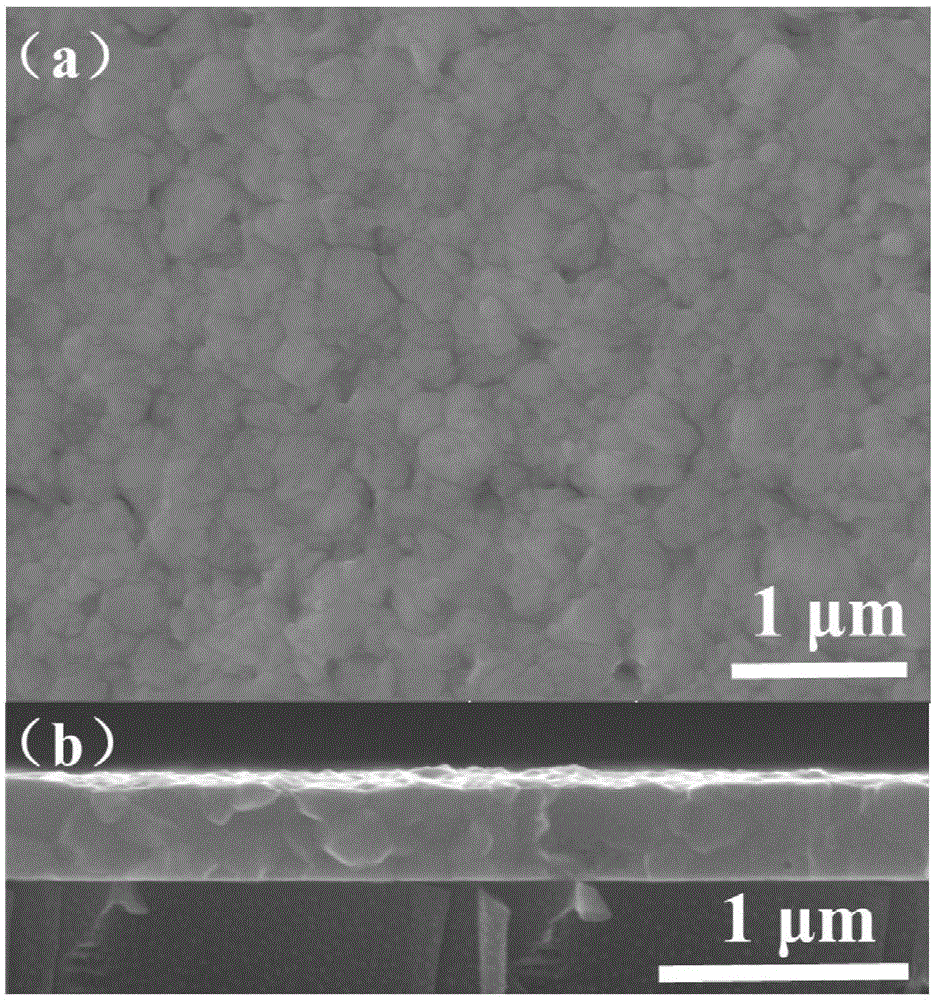

Image

Examples

Embodiment 1

[0025] Step 1: Take 2×2cm 2 The glass was ultrasonically cleaned with glass cleaner, acetone, and ethanol for 20 minutes, and then washed with N 2 blow dry.

[0026] Step 2: Add 2.3g of lead iodide and 0.8g of methyl ammonium iodide to a 10ml brown screw bottle, and then add 5ml of N,N-dimethylformamide and dimethyl sulfoxide to it, where N , The volume ratio of N-dimethylformamide and dimethyl sulfoxide is between 7:3 and 3:7. In order to promote the dissolution of the above solids, the screw bottle was sealed and placed on a magnetic stirrer at 70°C for 8 hours, and then sealed and placed on a hot plate at 70°C for use as solution A.

[0027] Step 3: Add 0.32g of zinc iodide and 0.16g of methylammonium iodide to a 10ml brown screw bottle, and then add 1ml of N,N-dimethylformamide solution to it. In order to promote the dissolution of the above solids, seal the screw bottle and place it on a magnetic stirrer at 70°C for 8 hours, then seal it and place it on a hot plate at ...

Embodiment 2

[0031] Step 1: Choose a piece with a size of 2×2cm 2 The glass was ultrasonically cleaned with glass cleaner, acetone, and ethanol for 20 minutes, and then washed with N 2 blow dry.

[0032] Step 2: Add 2.3g of lead iodide and 0.8g of methyl ammonium iodide to a 10ml brown screw bottle, and then add 5ml of N,N-dimethylformamide and dimethyl sulfoxide to it, where N , The volume ratio of N-dimethylformamide and dimethyl sulfoxide is between 7:3 and 3:7. In order to promote the dissolution of the above solids, seal the screw bottle and place it on a magnetic stirrer at 70°C for 8 hours, then seal it and place it on a hot plate at 70°C for use as solution A.

[0033] Step 3: Add 0.32g of zinc iodide and 0.16g of methylammonium iodide to a 10ml brown screw bottle, and then add 1ml of N,N-dimethylformamide solution to it. In order to promote the dissolution of the above solids, seal the screw bottle and place it on a magnetic stirrer at 70°C for 8 hours, then seal it and place i...

Embodiment 3

[0042] 1) Mix lead iodide and methyl ammonium iodide according to the molar ratio of lead:ammonium 1:1, and dissolve them in N,N-dimethylformamide, dimethyl sulfoxide or N,N-di In a mixed solution of methylformamide and dimethyl sulfoxide in any ratio, stirring at 60°C for 6 hours to obtain a perovskite precursor solution A, wherein the lead ion solubility of solution A is 0.5mol / L;

[0043] 2) Mix zinc iodide and methyl ammonium iodide according to the molar ratio of zinc:ammonium 1:1, dissolve them in N,N-dimethylformamide, and stir at 70°C for 8 hours to obtain calcium titanium Ore precursor solution B, wherein the zinc ion solubility in B solution is 0.5mol / L;

[0044] 3) Mix solution A in step 1) and solution B in step 2 according to a volume ratio of 95:5 to obtain a perovskite precursor solution, and stir at 70° C. for 4 hours to obtain a uniformly mixed solution;

[0045] 4) Put 2×2cm 2 The glass substrate was ultrasonically cleaned with glass cleaning agent, acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com