A kind of preparation method of Prussian blue/graphene/carbon fiber composite material

A technology of Prussian blue and composite materials, which is applied in the field of preparation of Prussian blue/graphene/carbon fiber composite materials, can solve the problems of high surface inertness and lack of chemically active functional groups, etc. The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

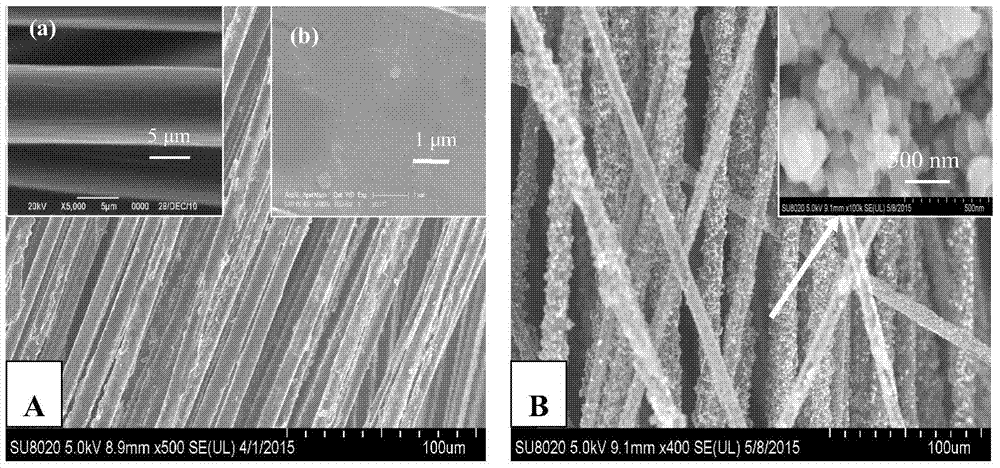

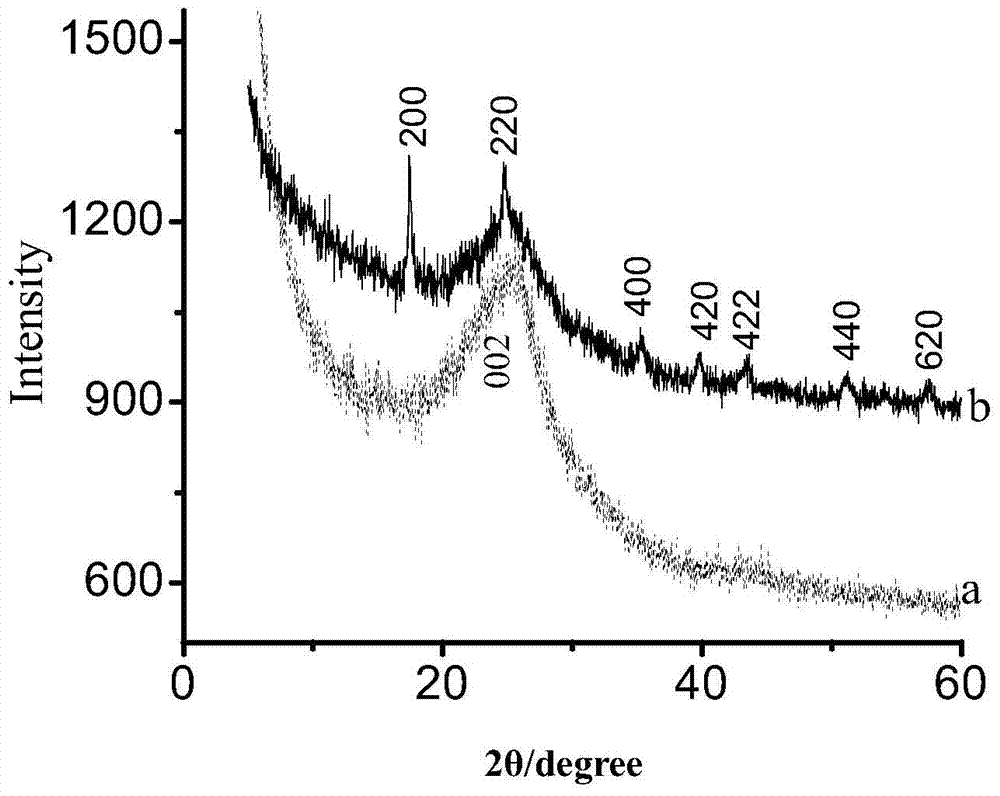

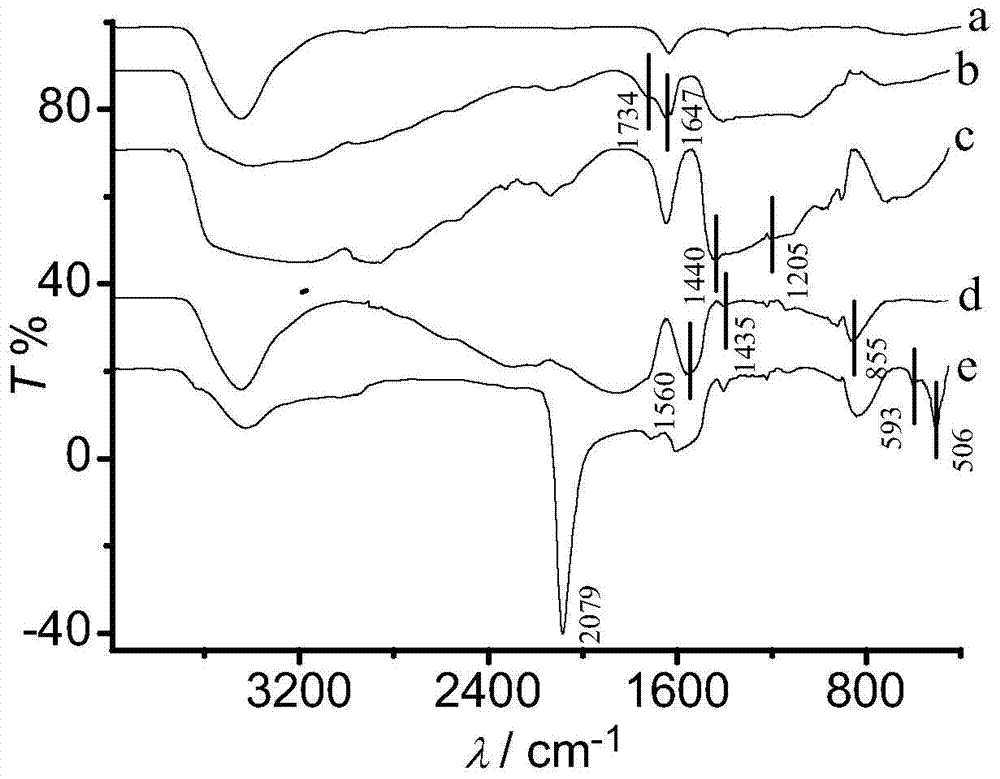

[0042] 1. Preparation of carbon fiber / graphene composite support (CFs / GNs)

[0043] ① Preparation of aminated graphene: Add 0.3g graphene oxide into 300mL absolute ethanol, mix well to make graphene oxide suspension, add 2g 1-ethyl-(3-dimethylaminopropyl) carbon Diimine and 200 g of dimethylethylenediamine were reacted at 70° C. for 1 hour to generate aminated graphene (GN).

[0044] ②Preparation of carboxylated carbon fiber: take conductive polyacrylonitrile carbon fiber as the working electrode, immerse it in 9.8g / L sulfuric acid solution, and anodize it at 1.8V for 30 minutes to form carboxylated carbon fiber, which is abbreviated as CFs;

[0045] ③Immerse 1g of CFs in 300mL of aminated graphene / acetone suspension with a concentration of 1.5g / L, adjust the pH of the solution to 5, add 3g of N-hydroxysuccinimide, and react at 70°C for 1 hour to form Single-layer graphene-modified carbon fibers (CFs / GN).

[0046] ④Immerse 1g of CFs / GN into 300mL of graphene oxide / ethanol su...

Embodiment 2

[0053] 1. Preparation of carbon fiber / graphene composite support (CFs / GNs)

[0054] ①Preparation of aminated graphene: Add 0.6g graphene oxide into 300mL dimethylformamide, mix well to make graphene oxide suspension, add 1g 1-ethyl-(3-dimethylaminopropyl ) carbodiimide and 50g of dimethylethylenediamine were reacted at 90° C. for 1.5 hours to generate aminated graphene (GN).

[0055] ②Preparation of carboxylated carbon fiber: take conductive polyacrylonitrile carbon fiber as the working electrode, immerse it in 9.8g / L sulfuric acid solution, and anodize it at 1.8V for 30 minutes to form carboxylated carbon fiber, which is abbreviated as CFs;

[0056] ③Immerse 1g of CFs in 300mL of aminated graphene / dimethylformamide suspension with a concentration of 2g / L, adjust the pH of the solution to 7, add 2g of N-hydroxysuccinimide, and react at 90°C for 1 hour , to generate single-layer graphene-modified carbon fibers (CFs / GN).

[0057] ④Immerse 1g CFs / GN into 300mL graphene oxide / di...

Embodiment 3

[0063] 1. Preparation of carbon fiber / graphene composite support (CFs / GNs)

[0064] ①Preparation of aminated graphene: Add 0.5g graphene oxide into 300mL acetonitrile, mix well to make a graphene oxide suspension, add 1.2g 1-ethyl-(3-dimethylaminopropyl)carbonitrile Imine and 150 g of dimethyl vinyl diamine were reacted at 30° C. for 2 hours to generate aminated graphene (GN).

[0065] ②Preparation of carboxylated carbon fiber: take conductive polyacrylonitrile carbon fiber as the working electrode, immerse it in 9.8g / L sulfuric acid solution, and anodize it at 1.8V for 30 minutes to form carboxylated carbon fiber, which is abbreviated as CFs;

[0066] ③Immerse 1g of CFs in 250mL of aminated graphene / acetonitrile suspension with a concentration of 1g / L, adjust the pH of the solution to 6, add 2g of N-hydroxysuccinimide, and react at 30°C for 1 hour to form a monolayer Graphene-modified carbon fibers (CFs / GN).

[0067] ④Immerse 1g of CFs / GN into 250mL of graphene oxide / aceton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com