Technique for sizing thick-walled seamless steel tubes through two-roller skew rolling mill and technique for rolling thick-walled seamless steel tubes through two-roller skew rolling mill

A technology of seamless steel pipe and skew rolling mill, which is used in metal rolling, rolling force/roll gap control, etc., can solve the problems of complex equipment and equipment, outward folding, narrow specification range, etc., and achieves high geometric dimensional accuracy and saves production. cost, the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

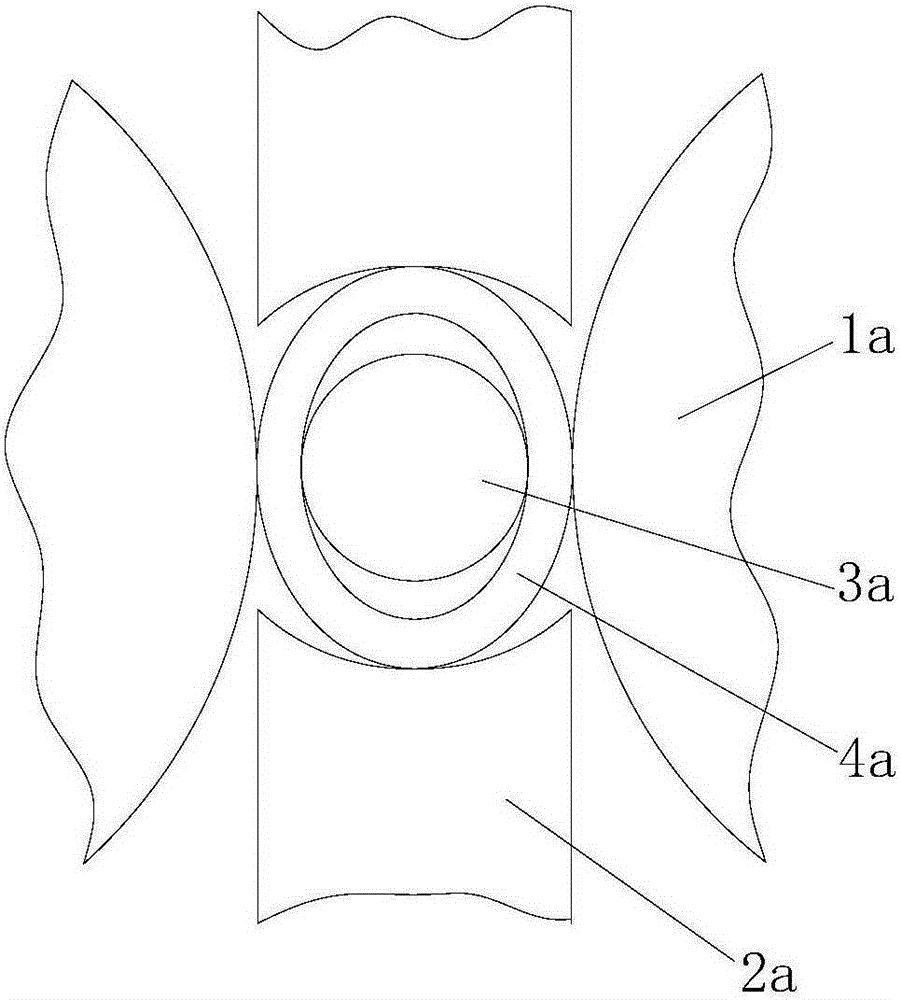

[0033] Example 1 The sizing process of thick-walled seamless steel pipes using a two-roll skew rolling mill

[0034] 1) If the outer diameter of the finished steel pipe to be obtained is 610mm, then adjust the roll 1 roll spacing of the two-roll skew rolling mill so that the roll 1 roll spacing is 616mm (610mm*1.01 times) the outer diameter of the finished steel pipe;

[0035] Adjust the guide disc distance of the two-roll skew rolling mill so that the guide disc distance is 628mm (616mm*1.02 times) of the roll distance of roll 1;

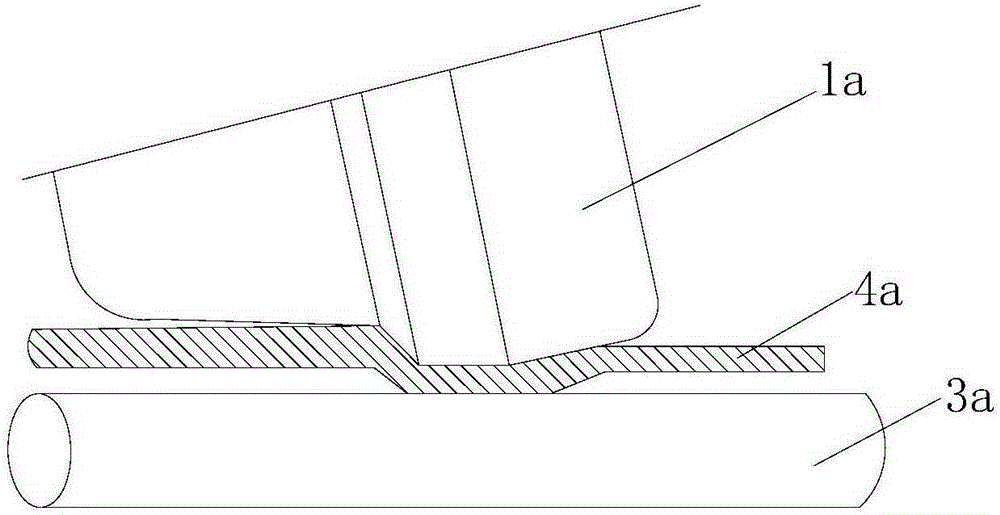

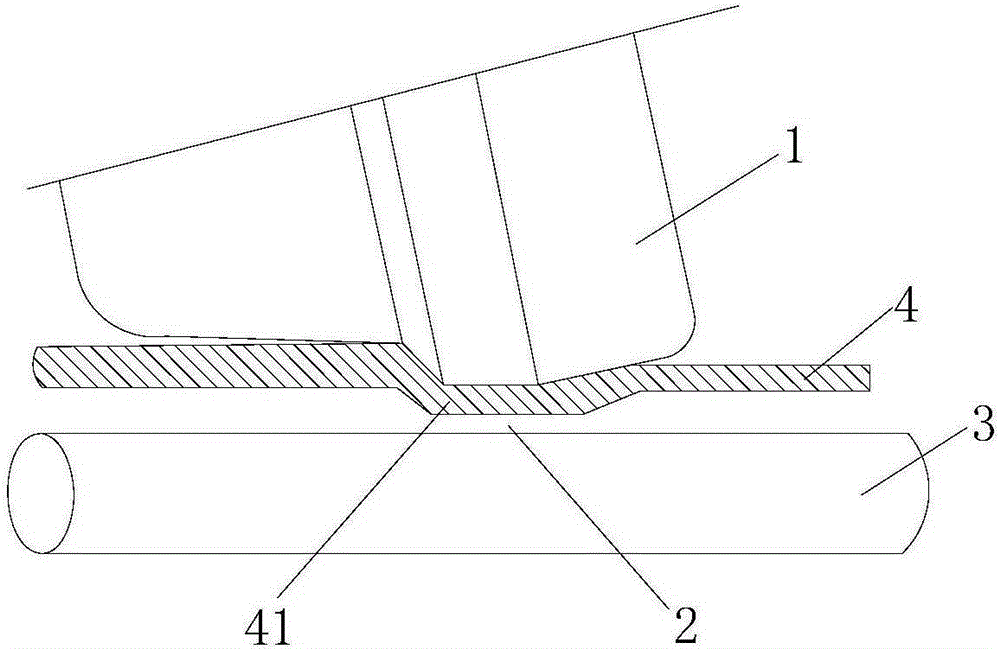

[0036] 2) Set the blank pipe 4 on the sizing mandrel 3 of the two-roll skew rolling mill, and carry out sizing rolling under the action of the roll 1 and the guide plate to obtain a thick-walled seamless steel pipe. The thickness of the thick-walled seamless steel pipe is The wall thickness is 120mm;

[0037] During sizing and rolling, the part of the blank pipe 4 that is in contact with the roll 1 is the rolling section 41, and there is always a ...

Embodiment 2

[0040] Embodiment 2 Rolling process of thick-walled seamless steel pipe

[0041] It includes a heating process, a piercing process, a wall reduction process and a sizing process in sequence, and the wall reduction process is carried out by a two-roll skew rolling mill.

[0042] The sizing process includes:

[0043] 1) If the outer diameter of the finished steel pipe is to be 660mm, then adjust the roll 1 roll distance of the two-roll skew rolling mill used during the wall reduction process so that the roll 1 roll distance is 1.01 times the outer diameter of the finished steel pipe;

[0044] Adjust the guide disc distance of the two-roll skew rolling mill so that the guide disc distance is 1.02 times the distance of roll 1;

[0045] 2) Replace the mandrel used in the wall-reducing process of the two-roll skew rolling mill with the sizing mandrel 3, and set the 4 sets of waste tubes obtained after the wall-reducing process on the sizing mandrel 3, and place them on the sizing m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com