Steel pilling-up protective method for serial type rolling mill

A technology of tandem rolling mills and rolled pieces, which is applied in the direction of metal rolling, metal rolling, roll safety equipment, etc., can solve the problems of out-of-control of rolled pieces, inaccurate calculation of rolled piece positions, and production stoppage, so as to achieve protection, Avoid equipment damage and personal injury, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

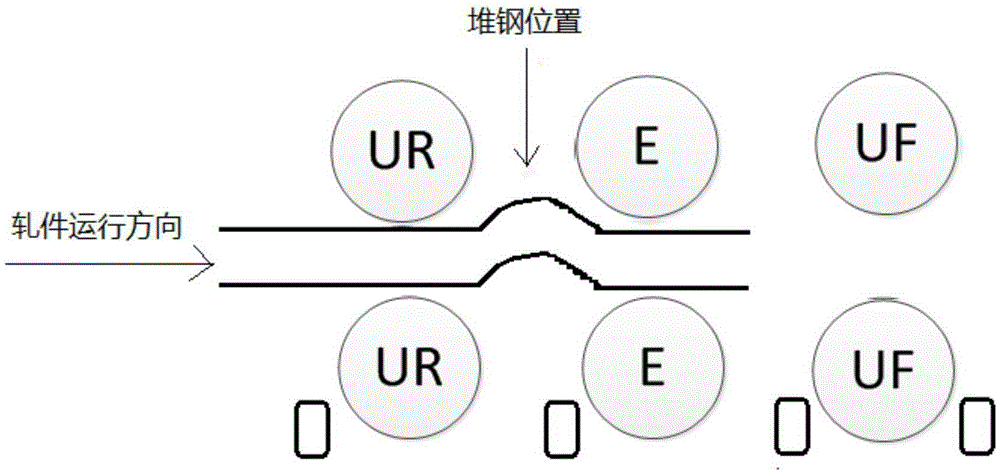

[0011] Such as figure 1 As shown, the rolling mill includes three stands of UR, E, and UF, and the rolled piece is 60kg / m heavy-duty steel rail. figure 1 The running direction of the rolled piece shown in is the running direction of the odd-numbered pass, and the running direction of the even-numbered pass is opposite to that of the odd-numbered pass. Hot metal detectors are installed on the entrance side and the exit side of the rolled piece of each stand. element.

[0012] After the billet bites into the three racks, the rolling speed generally does not cause steel holding accidents, but steel holding accidents will only occur during the steel biting process. Taking the entrance side of the E-frame of the odd track as an example, the control program is in the steel biting step, the automatic start condition is activated, and the hot metal detection element is used to determine that the end of the heavy rail enters the entrance side of the E-frame and reaches the exit side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com