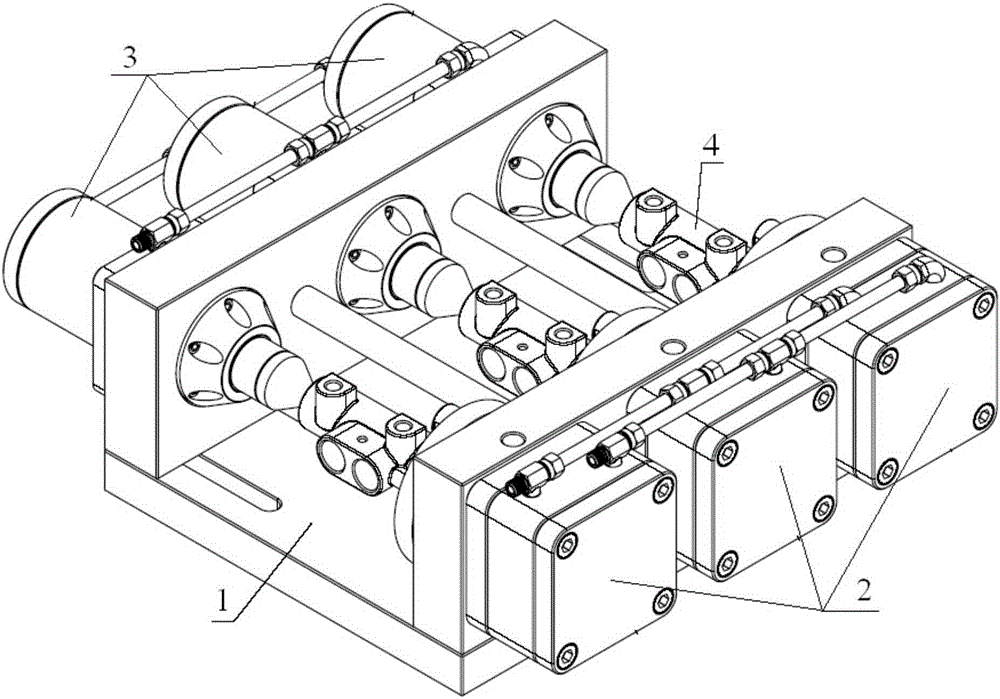

Automatic rotating clamp for multi-station main cylinder body

An automatic rotation, master cylinder technology, applied in the direction of manufacturing tools, clamping, positioning devices, etc., can solve the problems of high labor intensity, low production efficiency, many clamping times, etc., to reduce labor intensity and low maintenance costs. , The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

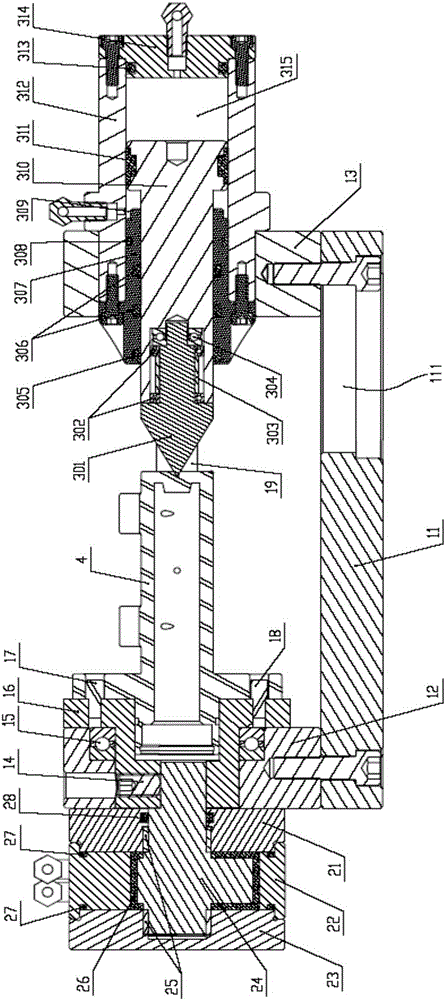

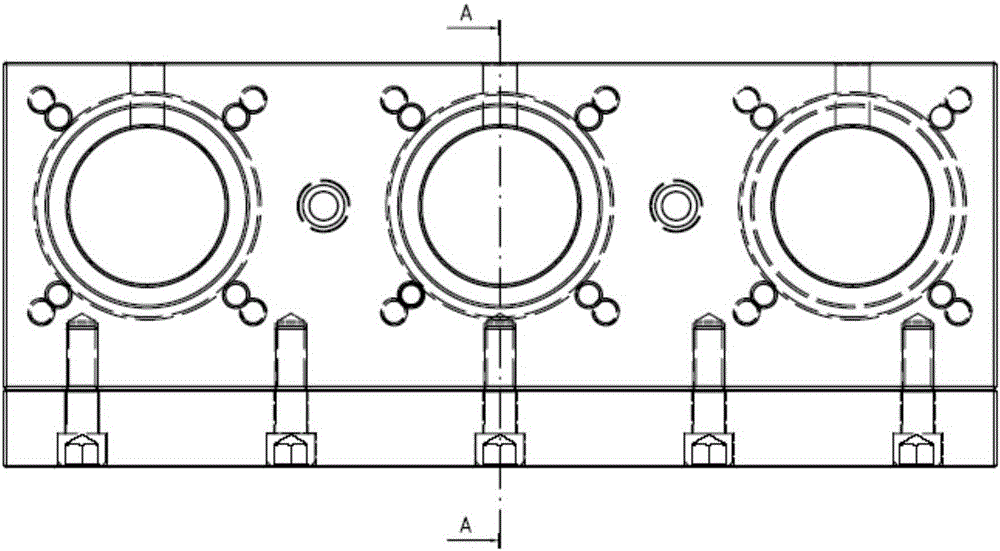

[0045] One embodiment of the present invention is: there are evenly distributed T-shaped slots 111 on the bottom plate 11 of the trough-shaped frame 1, which are used for adjusting the rear vertical plate 13 forward and backward along the T-shaped slots 111, and at the same time replace the corresponding pull rods 19, Realize the installation of main cylinder body 4 different lengths.

[0046] One embodiment of the present invention is: the fan angle α of the fan-shaped oil chamber is 1-160 degrees, Figure 5-4 As shown, it can be selected according to the processing needs of the workpiece. There is an input oil hole and an output oil hole at both ends of the fan-shaped oil chamber.

[0047] One embodiment of the invention is: the multifunctional sealing element 26 is a rectangular and circular integral structure, using rubber or polyurethane material, and the multifunctional sealing element 26 is installed in the groove 241 of the camshaft 24 to play a radial and axial role. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com