Abrasive paper production process and coating adhesive formula

A production process and technology of coating glue, applied in the direction of manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of scratches on the surface of the workpiece, poor quality of the sandpaper substrate, and the finish cannot meet the requirements, and achieve the surface flatness. High, excellent softness, good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described below in conjunction with specific embodiments.

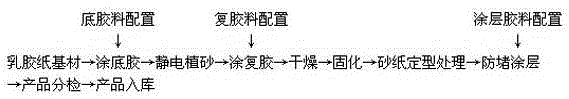

[0017] like figure 1 Shown, a kind of sandpaper production process and coating glue formula are characterized in that: described production process steps are as follows:

[0018] a. After the substrate is coated with primer, it is electrostatically sanded and dried;

[0019] b. Dry and cure after coating the glue;

[0020] c. Sandpaper shaping treatment;

[0021] d. Apply anti-blocking coating glue and dry it;

[0022] e. The products are put into storage after sorting.

[0023] Further, the formula of the coating glue, by weight percentage: 60% of lubricating filler, 10% of adhesive, 2% of antistatic agent, 28% of solvent, and the coating material of the coating glue has special lubricating properties for carbon fiber materials. And antistatic function, coated on the surface of sandpaper, sandpaper plays a lubricating and conductive effect when grinding carbon fiber materials...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com