Desktop-level 3D printer

A 3D printer, desktop-level technology, applied in the direction of additive processing, etc., can solve the problems of low precision of printed products, low printing precision, errors, etc., to achieve convenient control of feeding and discharging, convenient adjustment and positioning, Z-axis smooth motion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

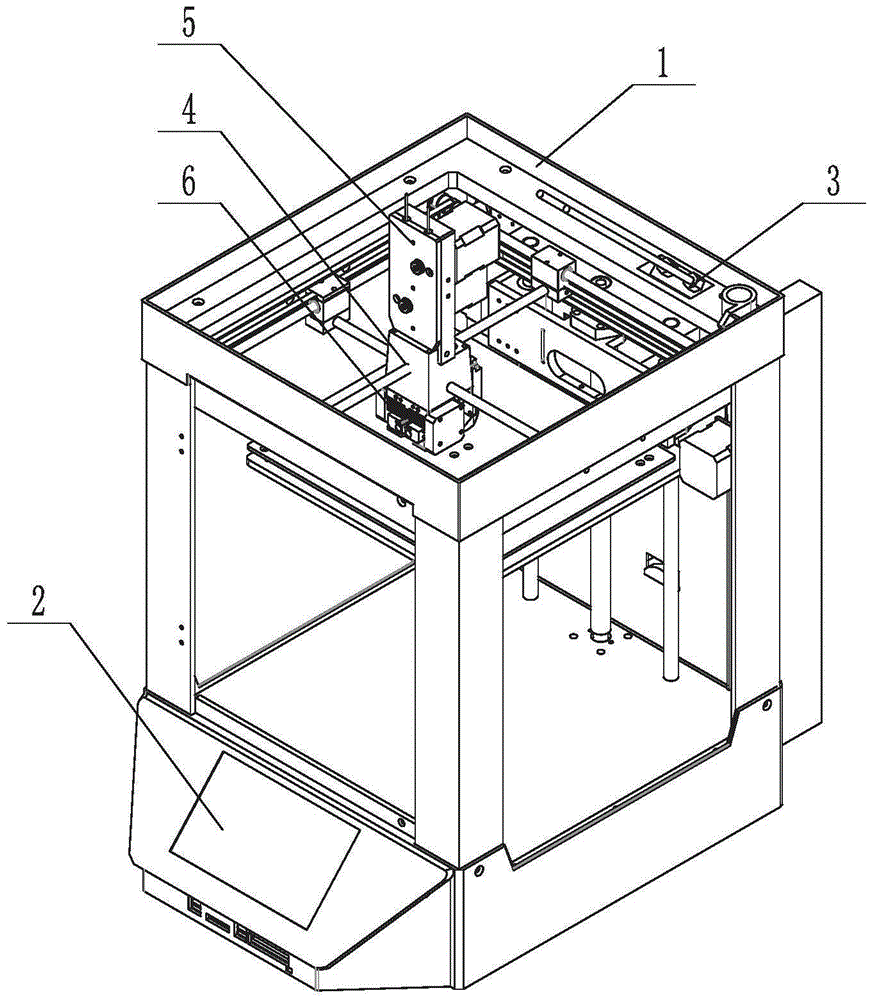

[0043] Embodiment one: if figure 1 , figure 2 and image 3 As shown, a desktop 3D printer includes a frame 1, a controller, a material transmission device 3, an XYZ axis motion device 4, a feeding device 5, and a nozzle device 6, and the material transmission device and the XYZ axis motion device are installed on On the frame, the feeding device and the nozzle device are installed on the XYZ axis movement device, the material transmission device is connected with the feeding device, the feeding device is connected with the nozzle device, and the controller is connected with the nozzle device. The material transmission device, the XYZ axis movement device, the feeding device, and the nozzle device are electrically connected, and it is characterized in that,

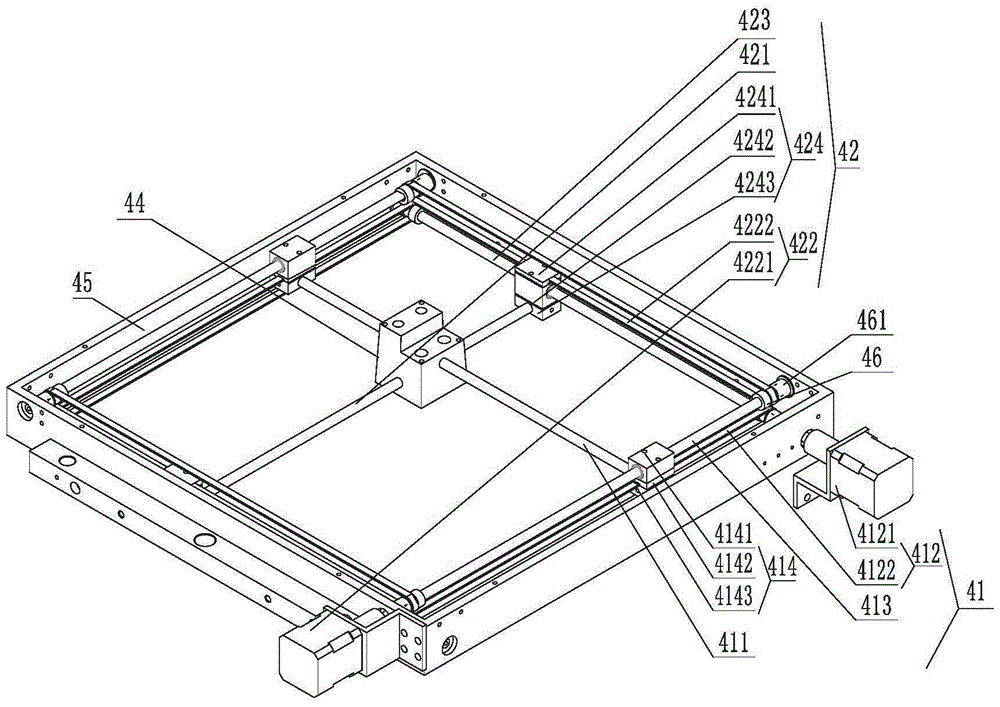

[0044] The XYZ axis motion device, the XYZ axis motion device includes an X axis motion assembly 41, a Y axis motion assembly 42, a Z axis lifting assembly 43, a print head carrier 44 and a fixed frame 45 for installing...

Embodiment 2

[0045] Embodiment two: if Figure 1-7 As shown, a desktop-level 3D printer includes a frame, a controller, a material transmission device, an XYZ axis motion device, a feeding device, and a nozzle device. The material transmission device and the XYZ axis motion device are installed on the frame. The feeding device and the nozzle device are installed on the XYZ axis movement device, the material conveying device is connected with the feeding device, the feeding device is connected with the nozzle device, and the controller is connected with the material conveying device , XYZ axis movement device, feeding device, and nozzle device are electrically connected, and it is characterized in that,

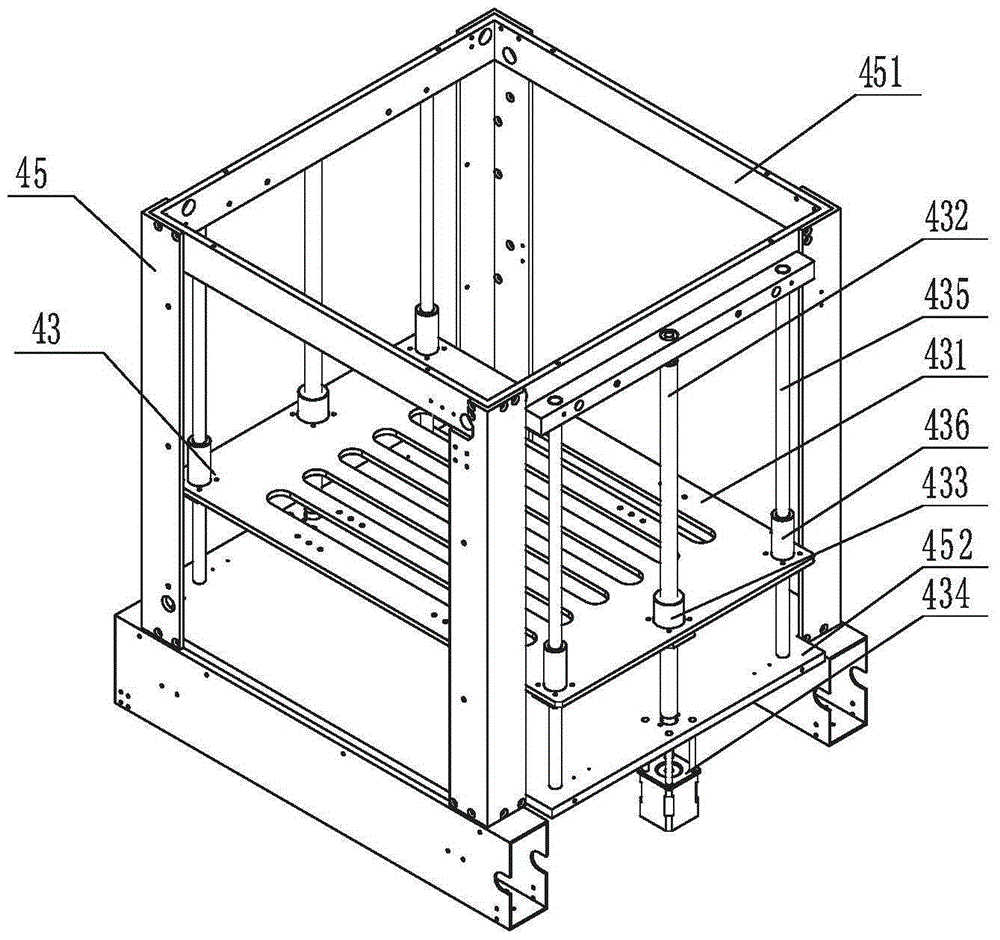

[0046] The XYZ axis motion device, the XYZ axis motion device includes an X axis motion assembly, a Y axis motion assembly, a Z axis lift assembly, a print head carrier for installing a 3D print head and a fixed frame, and the fixed frame is installed on the machine On the frame, the fixe...

Embodiment 3

[0057] Embodiment three: as Figure 1-7 As shown, a desktop-level 3D printer includes a frame, a controller, a material transmission device, an XYZ axis motion device, a feeding device, and a nozzle device. The material transmission device and the XYZ axis motion device are installed on the frame. The feeding device and the nozzle device are installed on the XYZ axis movement device, the material conveying device is connected with the feeding device, the feeding device is connected with the nozzle device, and the controller is connected with the material conveying device , XYZ axis movement device, feeding device, nozzle device are electrically connected.

[0058] The XYZ axis motion device, the XYZ axis motion device includes an X axis motion assembly, a Y axis motion assembly, a Z axis lift assembly, a print head carrier for installing a 3D print head and a fixed frame, and the fixed frame is installed on the machine On the frame, the fixed frame includes a quadrangular upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com