Medium temperature coal pitch modification method and product

A technology of coal tar pitch and medium temperature, which is applied in the field of modification of medium temperature coal tar pitch, can solve the problems of complex modification process, difficult industrial application, expensive modifier, etc., and achieves simple process, increased β resin content, increased softening point and high temperature. The effect of the focus value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

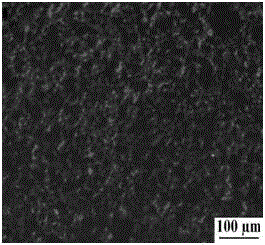

[0022] Embodiment 1: the anhydrous AlCl 3 Mix with medium-temperature coal tar pitch crushed to a particle size below 0.1mm at a weight ratio of 6wt% in a V-type mixer for 60 minutes, and then send it into the reactor; freely raise the temperature to 100°C and keep it for half an hour, and then set the temperature at 5°C / min Raise the temperature to 220°C and keep it warm for 3 hours. After cooling, take out the modified coal tar pitch and wash it three times with hydrochloric acid with a concentration of 0.1mol / L to remove the modifier. This is the prepared modified coal tar pitch. attached figure 1 That is the optical microstructure of the prepared modified coal tar pitch after carbonization at 420°C for 60 minutes.

Embodiment 2

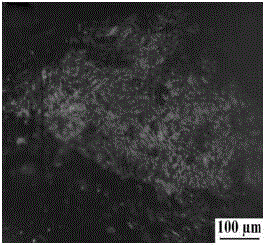

[0024] Anhydrous AlCl 3 Mix with medium-temperature coal tar pitch crushed to a particle size below 0.1mm at a weight ratio of 6wt% in a V-type mixer for 1 hour and then send it into the reactor; freely raise the temperature to 100°C and keep it for half an hour, and then set the temperature at 5°C / min Raise the temperature to 260°C and keep it warm for 3 hours. After cooling, take out the modified coal tar pitch and wash it three times with hydrochloric acid with a concentration of 0.1mol / L to remove the modifier. This is the prepared modified coal tar pitch. attached figure 2 This is the optical microstructure of the prepared modified coal tar pitch after being carbonized at 420°C for 60 minutes in a crucible resistance furnace.

Embodiment 3

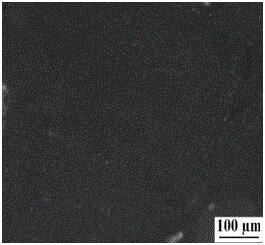

[0026] Anhydrous AlCl 3 Mix with medium-temperature coal tar pitch crushed to a particle size below 0.1mm at a weight ratio of 6wt% in a V-type mixer for 1 hour and then send it into the reactor; freely raise the temperature to 100°C and keep it for half an hour, and then set the temperature at 5°C / min The heating rate was raised to 300°C, and the temperature was kept for 3 hours. After cooling, the modified coal tar pitch was taken out, and washed three times with hydrochloric acid with a concentration of 0.1mol / L to remove the modifier. The modified coal tar pitch was obtained. attached image 3 That is the optical microstructure of the prepared modified coal tar pitch after carbonization at 420°C for 60 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com