Pteroceltis tatarinowii bark processing method

A processing method, the technology of green sandalwood skin, applied in pulp beating method, pulping with inorganic alkali, chemical/chemical mechanical pulping, etc., can solve the problems affecting the production and preservation of rice paper works, uneven wet strength, long vertical and horizontal fractures Uneven and other problems, to achieve the effect of improving the appearance quality, the same wet strength, and the same tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

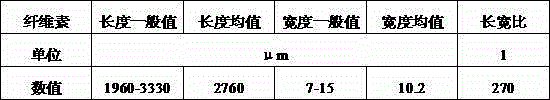

Image

Examples

Embodiment

[0016] A processing method of green sandalwood bark, the processing method of green sandalwood bark comprises the following steps:

[0017] (1) Cut the collected green sandalwood bark into about 1.2 meters, add an appropriate amount of sodium hydroxide, put it into the green sandalwood steaming stove, and cook it under water for 12-16 hours at room temperature, until the raw green sandalwood skin has a Kappa value of 22.5 -26.2 can be out of the cage;

[0018] (2) Soak the green sandalwood bark out of the cage in water at 10-15°C, add chlorine dioxide and bleach for 20-40 minutes, and after testing the whiteness to 72-80, wash it in running water;

[0019] (3) Remove the branches and bones, and remove the impurities and waste in the green sandalwood bark while drying;

[0020] (4) The green sandalwood bark from which impurities have been removed is put into a beater for beating after passing through the pestle, the beating degree is 26-28, and the wet weight is 7-9 degrees; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com