Integrated anti-floating structure of underground diaphragm wall and concrete structure bottom plate and construction method of integrated anti-floating structure

An underground diaphragm wall and concrete structure technology, applied in underwater structures, infrastructure engineering, excavation, etc., can solve the problems of long construction period, short construction period, cumbersome procedures, etc., and achieve the effect of large amount of engineering and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

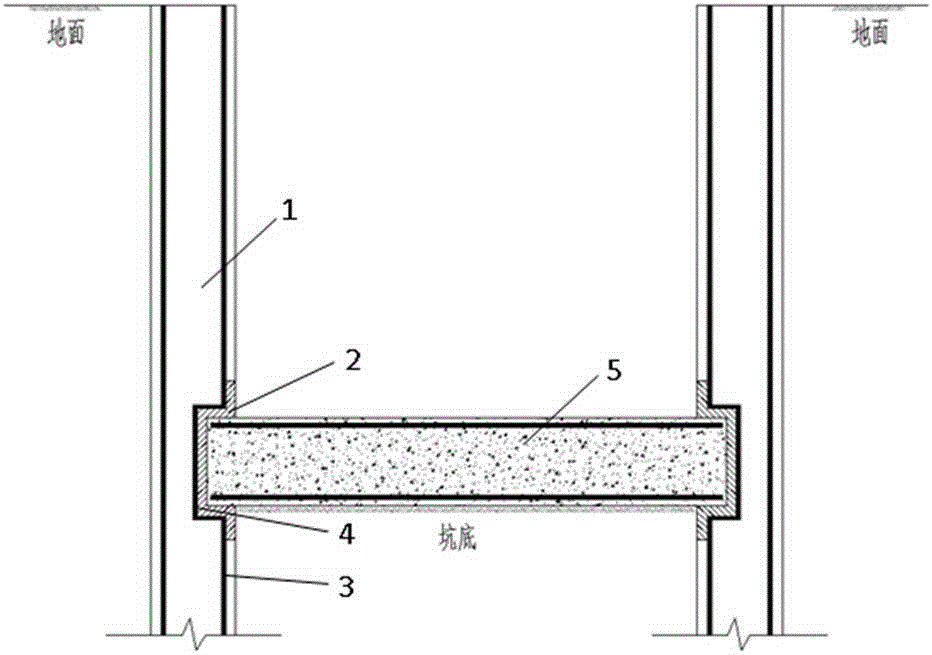

[0020] See attached figure 1 , which is a schematic cross-sectional view of an overall anti-floating structure in which an underground diaphragm wall and a concrete floor are embedded with each other provided in this embodiment; , the reinforcement cage and the U-shaped steel are fixed through the welding point 4, and the two ends of the concrete structure bottom plate 5 are respectively placed in the steel grooves of the U-shaped steel, so that the underground diaphragm wall and the concrete bottom plate form an integral anti-floating structure embedded with each other. In this structure, the underground continuous wall used for excavation and maintenance of deep foundation pit and the concrete bottom plate used for the permanent structure in the foundation pit are embedded with each other through steel grooves, so that the ground continuity and the structural bottom plate form an integral force-bearing structure, thus, in the foundation pit During the excavation process, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com