A shear-resistant pull-out connector

A connecting piece and anti-drawing technology, which is applied in the direction of construction and building structure, can solve the problems of inconvenient laying of steel mesh, increased construction complexity, increased height of ribs, etc., and achieves simple structure, convenient construction, and guaranteed holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

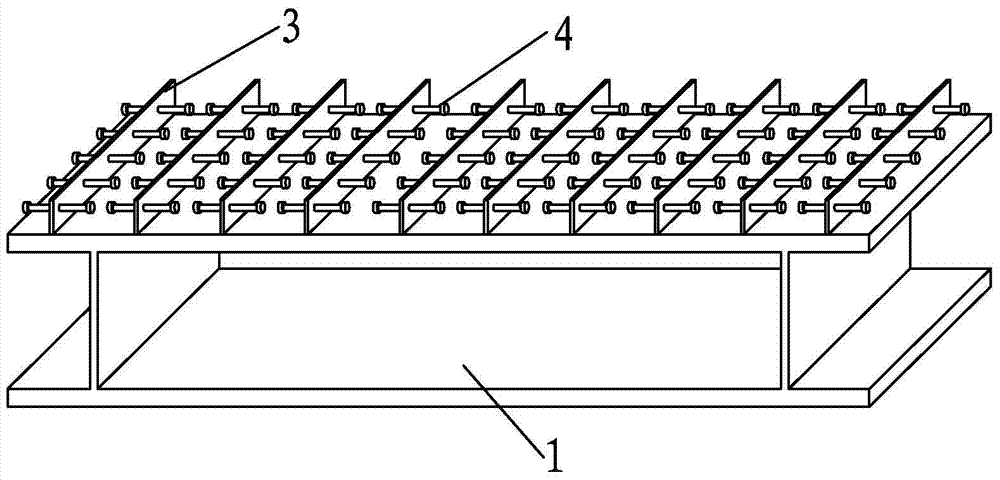

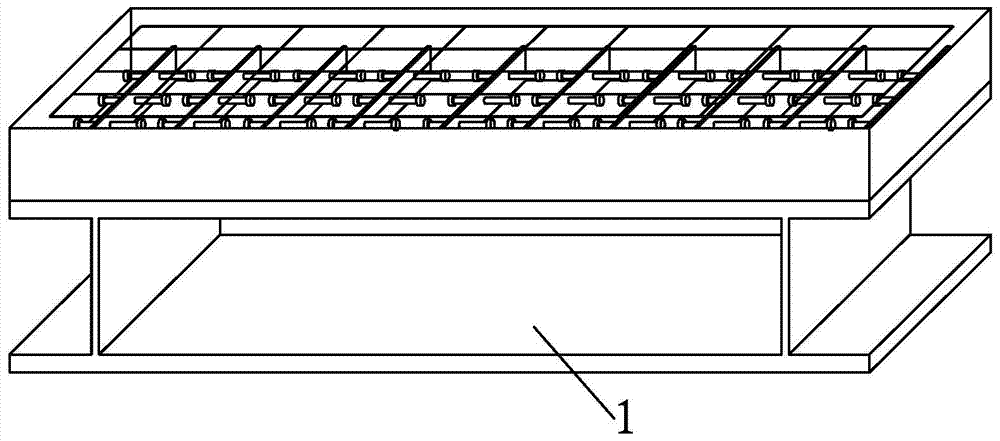

[0024] A shear-resistant and pull-resistant connector of the present invention can fix the steel structure 1 and the concrete structure 2 together to form a whole under common force. The steel structure 1 is I-shaped steel. Of course, other common steel structures can also be selected. .

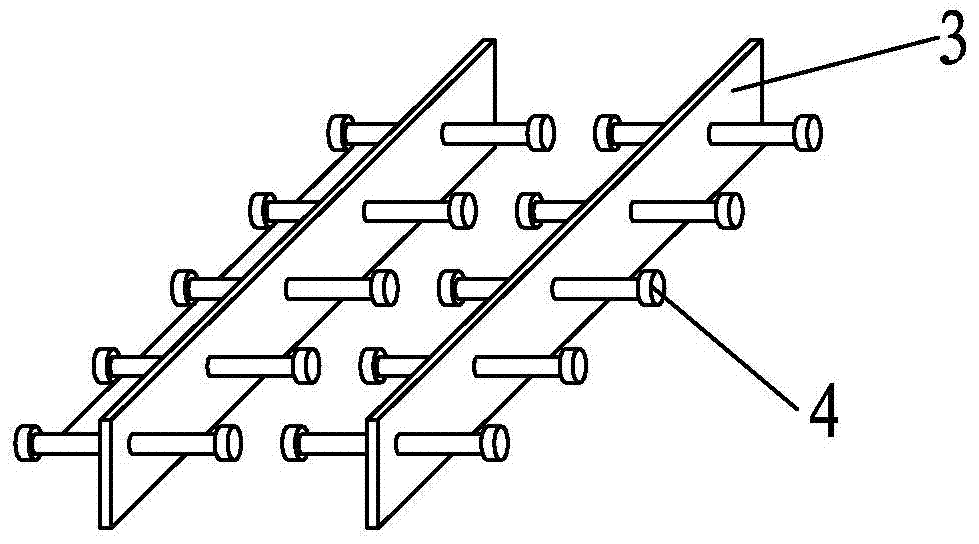

[0025] like Figure 1-4 As shown, a shear-resistant and pull-out connector includes a plurality of stiffening ribs 3 vertically arranged on the upper surface of a steel structure 1 and a plurality of studs 4 welded on both sides of the stiffening rib 3 . The stiffeners 3 are arranged in parallel along the length direction of the steel structure 1 .

[0026] The specifications of each stud 4 are the same, and each stud 4 is welded side by side and horizontally on both sides of the stiffener 3 along the length direction of the stiffener 3, so as to provide the concrete structure 2 with the shear strength in the horizontal direction and the vertical strength. Lift-off strength in the vertical...

Embodiment 2

[0031] In this embodiment, the structure of a shear-resistant and pull-resistant connector of the present invention is skillfully combined with the structure of the PBL shear member, such as Figure 5 As shown, specifically, several through-holes 5 are opened at the positions corresponding to the two adjacent stiffeners 3, and the same peg 4' penetrates through the corresponding through-holes 5 on the two stiffeners 3. , The studs 4 and the studs 4' are distributed at intervals on both sides of the same stiffener 3, so that a shear-resistant and pull-out resistant connector of the present invention is used in conjunction with a PBL shear member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com