Novel high-speed and high-precision multi-axis servo motion controller circuit

A servo motion, high-precision technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of high hardware development cost, low degree of automation, and low system scalability, and achieve strong software upgrade capabilities, good real-time performance, and system The effect of simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

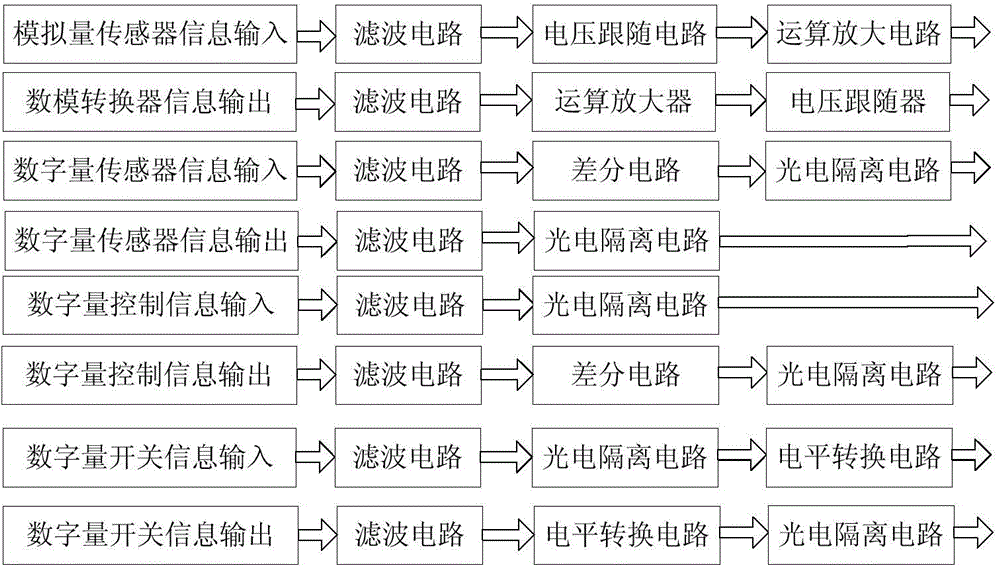

[0019] A new type of high-speed and high-precision multi-axis servo motion controller circuit, in which the servo motion controller has 64 points of general I / O, 32 points of digital optical isolation output, 32 points of digital optical isolation input, 32 analog inputs, 4 External communication interface and a control network bus interface.

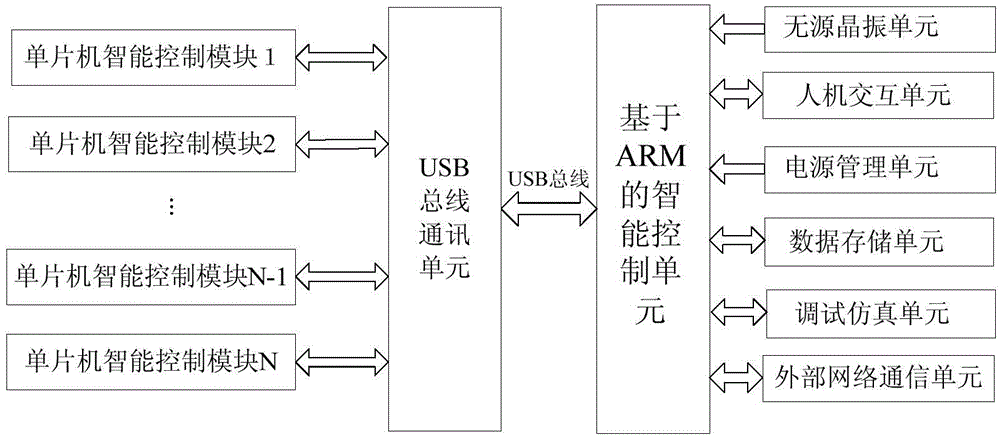

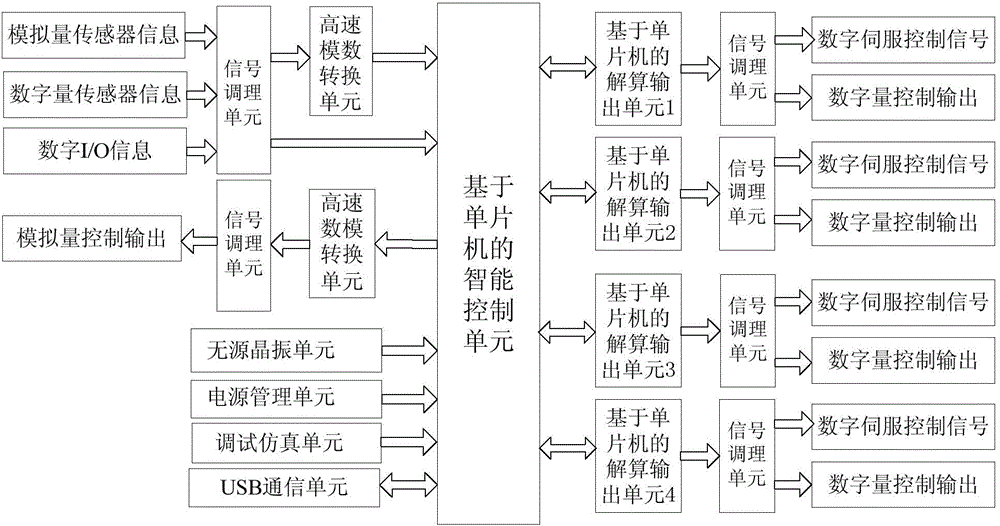

[0020] like figure 1 As shown, the hardware circuit includes an ARM-based intelligent control unit, an SCM intelligent control module, a USB bus communication unit, a data storage unit, an external network communication unit, a power management unit, a debugging simulation unit, a passive crystal oscillator unit and a human-computer interaction unit; Among them, the SCM intelligent control module includes an intelligent control unit based on a single-chip microcomputer, a high-speed analog-to-digital conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com