Method for manufacturing brand logo and trademark label using synthetic resin film

A synthetic resin and marking technology, applied to cardboard items, instruments, identification devices, etc., can solve the problems of unsmooth printing, color state, drop, and difficulty in reflecting a variety of colors, etc., to achieve elegance and beauty. Elegant style, the effect of improving mass production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention are described below with reference to the accompanying drawings. Through the following detailed description, the purpose, structure and characteristics of the present invention will be more clearly understood.

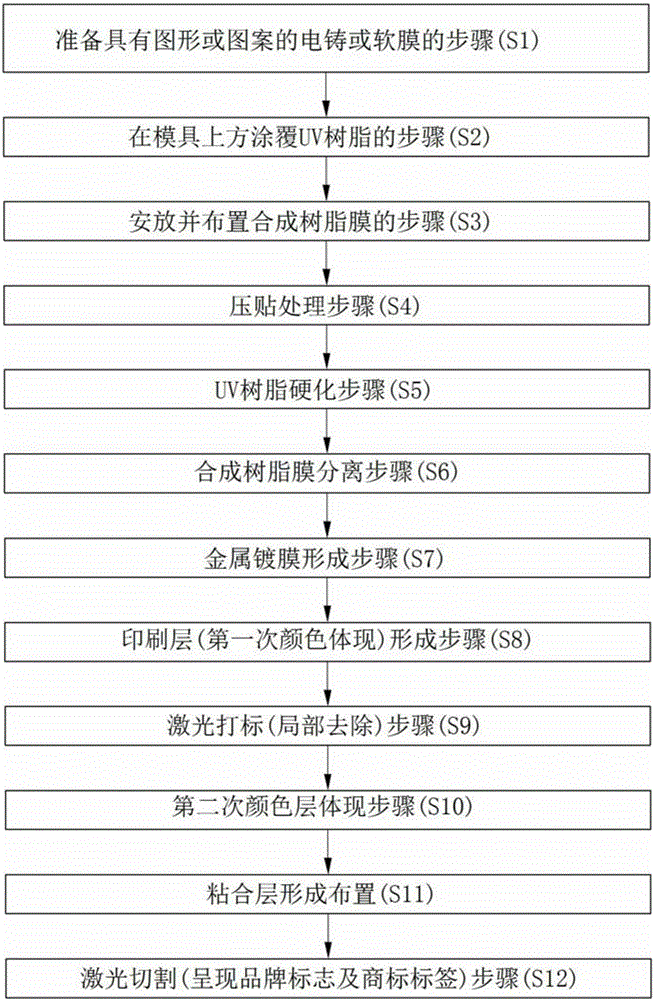

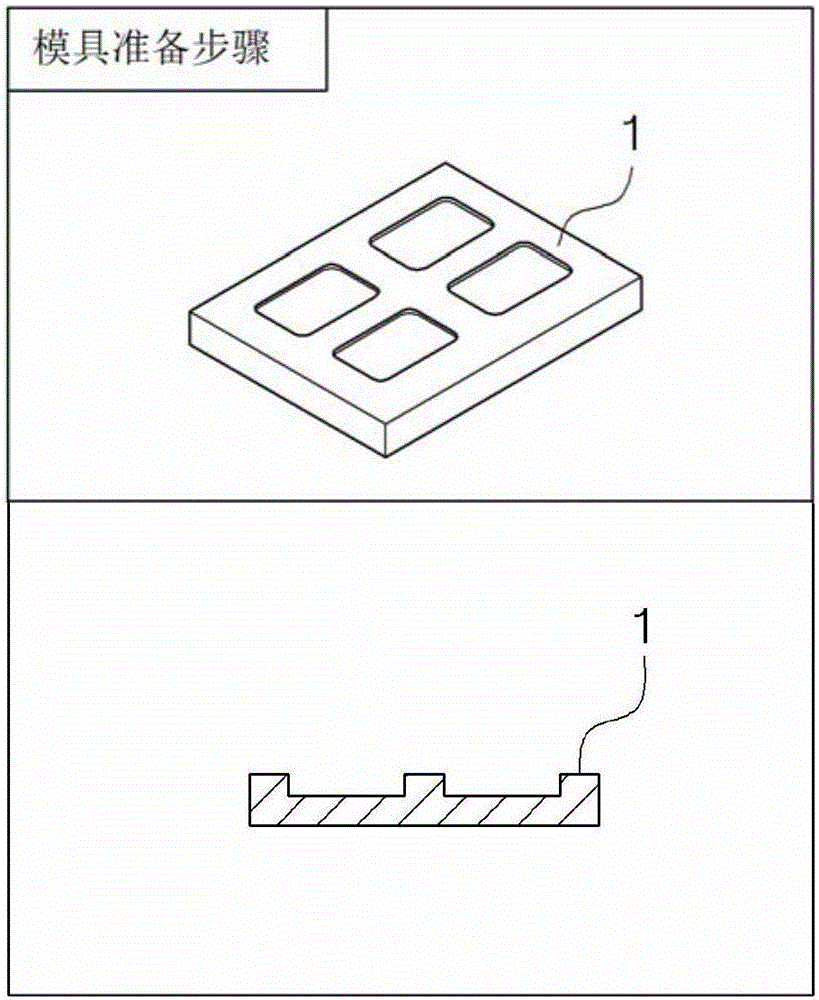

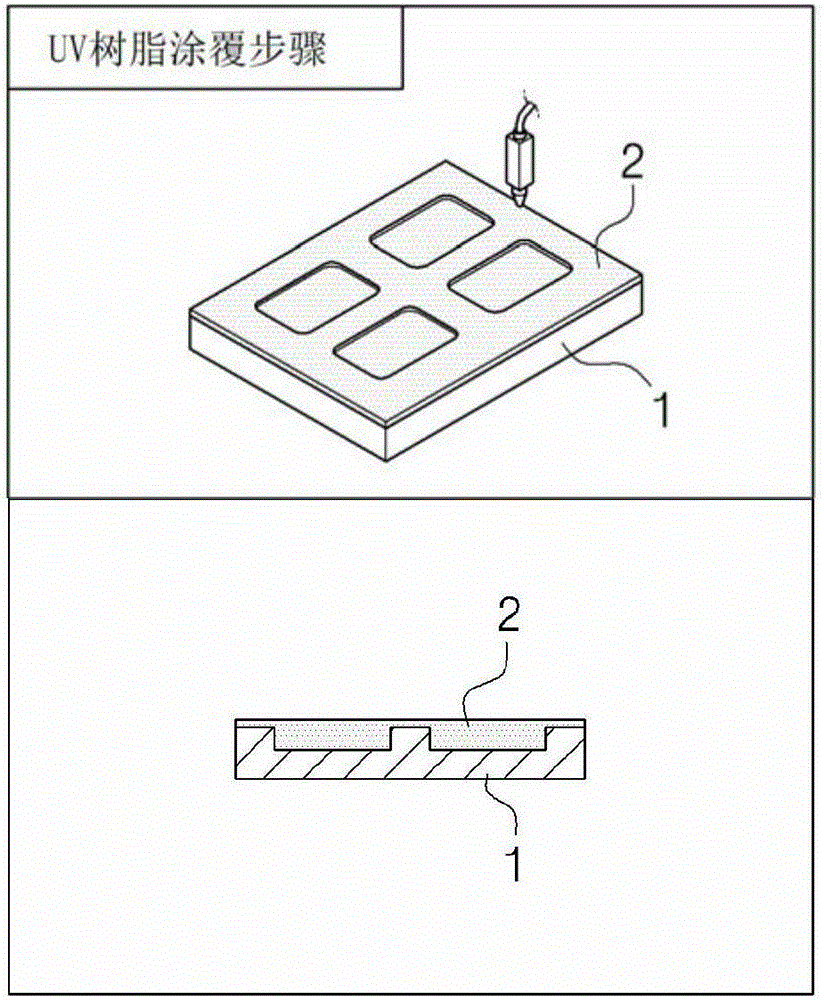

[0028] refer to figure 1 , Figure 2a to Figure 2k , the method for making a brand logo and a trademark label using a synthetic resin film according to an embodiment of the present invention is described as follows.

[0029] Such as Figure 2a As shown, prepare a mold 1-step S1 having various patterns or figures required by customers such as a rotating shape (convoluted shape) or a wave shape (water wave shape) or a hologram (interference fringe).

[0030] At this time, in order to improve the precision and fineness of the pattern in the above-mentioned mold 1, it is better to use an electroforming mold made by electroforming (electroforming), and in order to save the pressure of manufacturing costs, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com