Solid two-half-retainer two-sided electrical riveting processing method

A processing method and cage technology, which is applied in the field of bearing riveting, can solve problems such as insufficient adhesion between cold heading nail heads and cages, separation between rivets and cages, and reduced fracture resistance, achieving stable and controllable quality, Avoid rivet breakage and improve riveting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

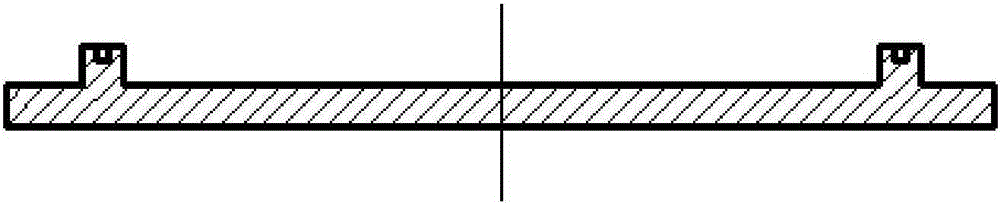

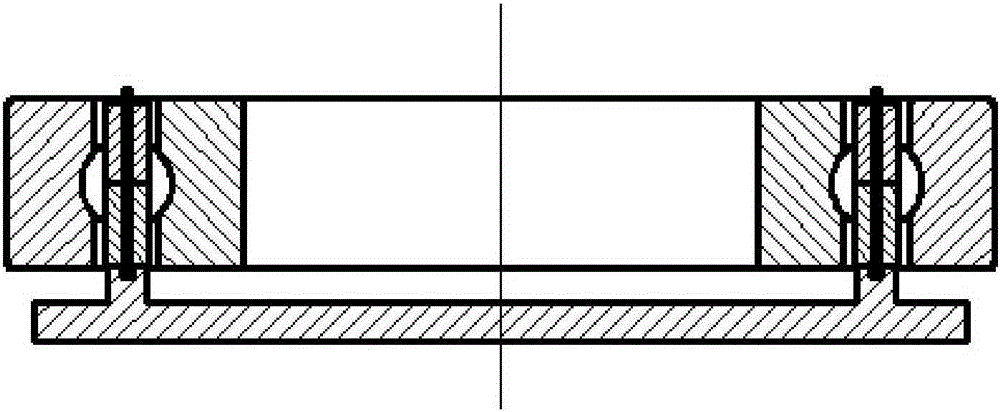

[0039] Specific implementation mode 1: This implementation mode is a method of electric riveting on both sides of a solid double-half cage, which is specifically completed according to the following steps:

[0040] 1. Nail cutting: When calculating single-sided electric riveting, the length L of the end surface of the rivet rod exposed to the cage 1 , according to the length L 3 Cut the rivet wire to obtain the length L 3 rivet rod, and L 3 = 2L 1 +L 2 , L 2 is the depth of the rivet hole to be riveted; then the length is L 3 The rivet rod is subjected to stress relief annealing treatment and deburring acute angle treatment in turn to obtain the rivet rod to be riveted;

[0041] 2. Preparation of nailed tires:

[0042] Prepare the nailing mold with annular groove according to the bearing to be riveted. The depth of the nailing mold groove ensures that the length D of the end surface of the cage is exposed after the rivet rod to be riveted is inserted into the rivet hole...

specific Embodiment approach 2

[0062] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the length L of the end surface of the cage to be riveted by the rivet rod to be riveted in step 1 1 =k 1 d, d is the diameter of the rivet rod to be riveted, k 1 is a coefficient, and when d=Φ1.0, k 1 =1.7; when d=Φ1.2, k 1 =1.65; when d=Φ1.5, k 1 =1.55; when d=Φ2.0, k 1 =1.52; when d=Φ2.5, k 1 =1.43; when d=Φ3.0, k 1 = 1.40. Others are the same as the first embodiment.

specific Embodiment approach 3

[0063] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the rivet wire in step 1 is ML15 steel wire, 1Cr18Ni9 steel wire or 1Cr18Ni9Ti steel wire. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com